Introduce:

DELO DUALBOND IC343 is an isotropic electrically conductive adhesive by adding conductive silver particles (Ag) to the glue, so the glue has very high conductivity, the volume resistance is only about 0.1 mOhm.cm. IC343 glue has many advantages such as:

- Glue is derived from modified polycarbamine acid, 1 component, no solvent.

- The glue can be quickly fixed by light in just a few seconds, then cured at a low temperature.

- Glue is thixotropic, anti-creep when applying glue.

- Compliant with RoHS 2015/863/EU standard;

- Halogen-free according to IEC 61249-2-21;

- Compliant with VOC volatile organic matter content limits according to GB33372-2020.

Application:

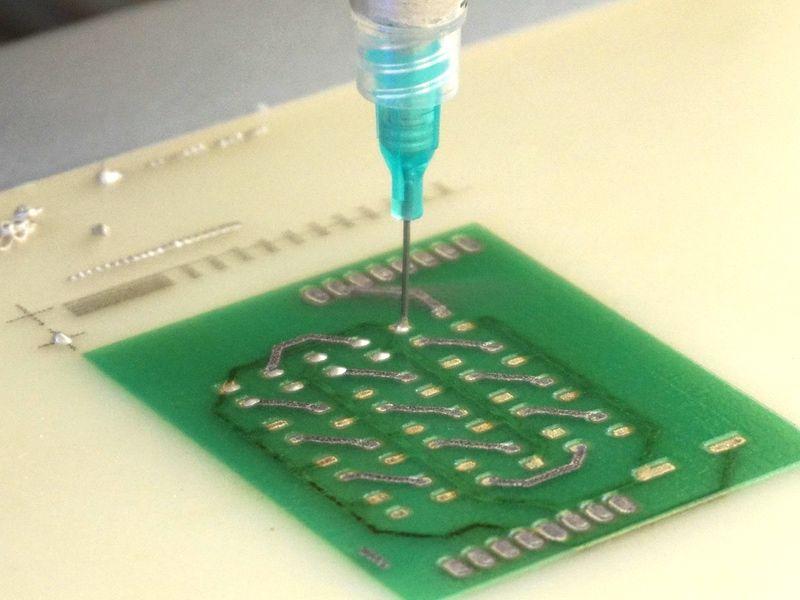

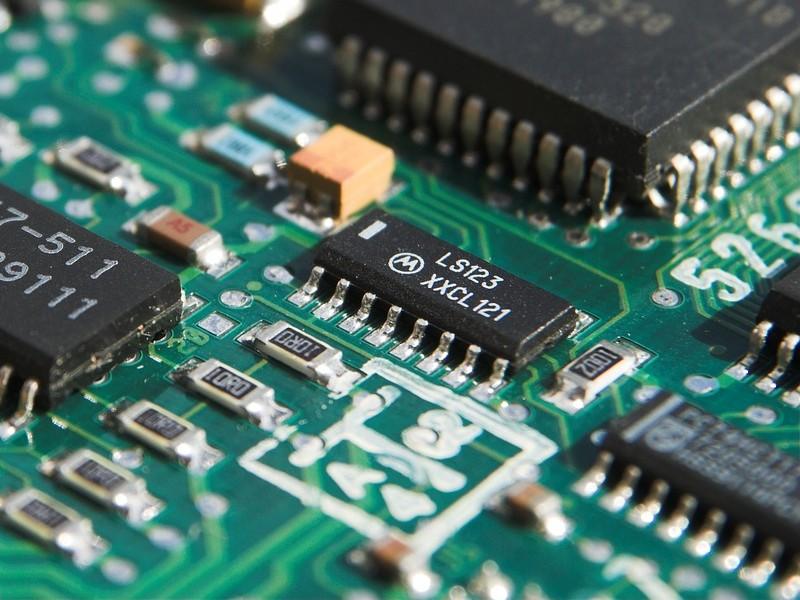

- IC343 glue is specialized in gluing electronic component pins on printed PCB boards, repairing electronic components.

- To use the adhesive effectively, it is recommended to use a specialized DELO dispensing such as DELOMAT 101, the surface to be bonded should be clean, dry, free of dust or grease.

- For a clean and well-activated surface, use the DELOTHEN surface cleaner.

- Suitable temperature range: -40 ~ +130 oC.

Specifications:

Curing:

- Use UV or visible light with wavelengths 365 and 400 nm.

- Refer to the standard wavelength range of DELOLUX 20/50/80 lamps.

Lamp Type | DELOLUX 20/50/80 | ||

Wavelength Range (nm) | 365, 400 | ||

UV exposure time | 1~5 s | ||

Curing time (in forced drying oven) | 80 o C | 90 o C | 100oC |

10 minutes | 15 minutes | 30 minutes | |

Technical parameters:

Stabilization time to room temperature | Container volume <10 ml | 30 minutes | |

Container volume <50 ml | 1 hour | ||

Time allowed to dispense glue: | 72 h | ||

Storage time (at -40 ~ -15 o C) | 6 months | ||

Color (with 1.0 mm adhesive layer): | Silver gray, opaque | ||

Density: | 3.0 g/cm3 | ||

Viscosity (Liquid, Rheometer measurement, PP20, gap 200 μm, shear rate 10 1/s): | 42000 mPa.s | ||

Glue surface after curing | Dry, hard | ||

Compression shear strength: | FR4/FR4 | 12 MPa | |

FR4/PBT | 7 MPa | ||

PBT/PBT | 4 MPa | ||

PC/ABS | 10 MPa | ||

PC/PC | 13 MPa | ||

PETP/PETP | 5 MPa | ||

CTE coefficient of thermal expansion in the range 35~150 0 C: | 150 ppm/K | ||

Shrinkage: | 2.2 %vol. | ||

Water Absorption: | 0.2 %wt. | ||

Thermal conductivity (ASTM E 1461): | 1.5 W/(m.K) | ||

Electrically Resitance: | 0.11 mOhm.cm | ||

Contact HUST Vietnam for more detailed information.

HUST Vietnam is proud to be the exclusive distributor of adhesive, dispensing equipment, UV curing lamp, and technology transfer from DELO in Vietnam!