Application of DELO adhesive in production | HUST Vietnam

MEDMIX - Disposable Static Mixers

- Medmix Industry offers a wide range of static and dynamic mixers compatible with cartridge-based systems and other meter-mix-dispense equipment.

- Mixing tips for two-component materials See more

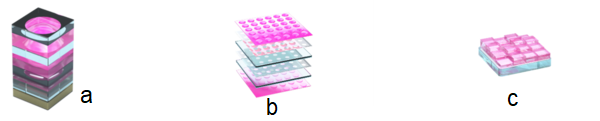

Cheaper and simpler micro-optics production

Thanks to micro- and nano-optics, ever more compact optical systems are being created. These pave the way for completely new functionalities that conventional optics cannot achieve. UV imprint, meanwhile, makes the cost-efficient mass production of such optics has become a reality.

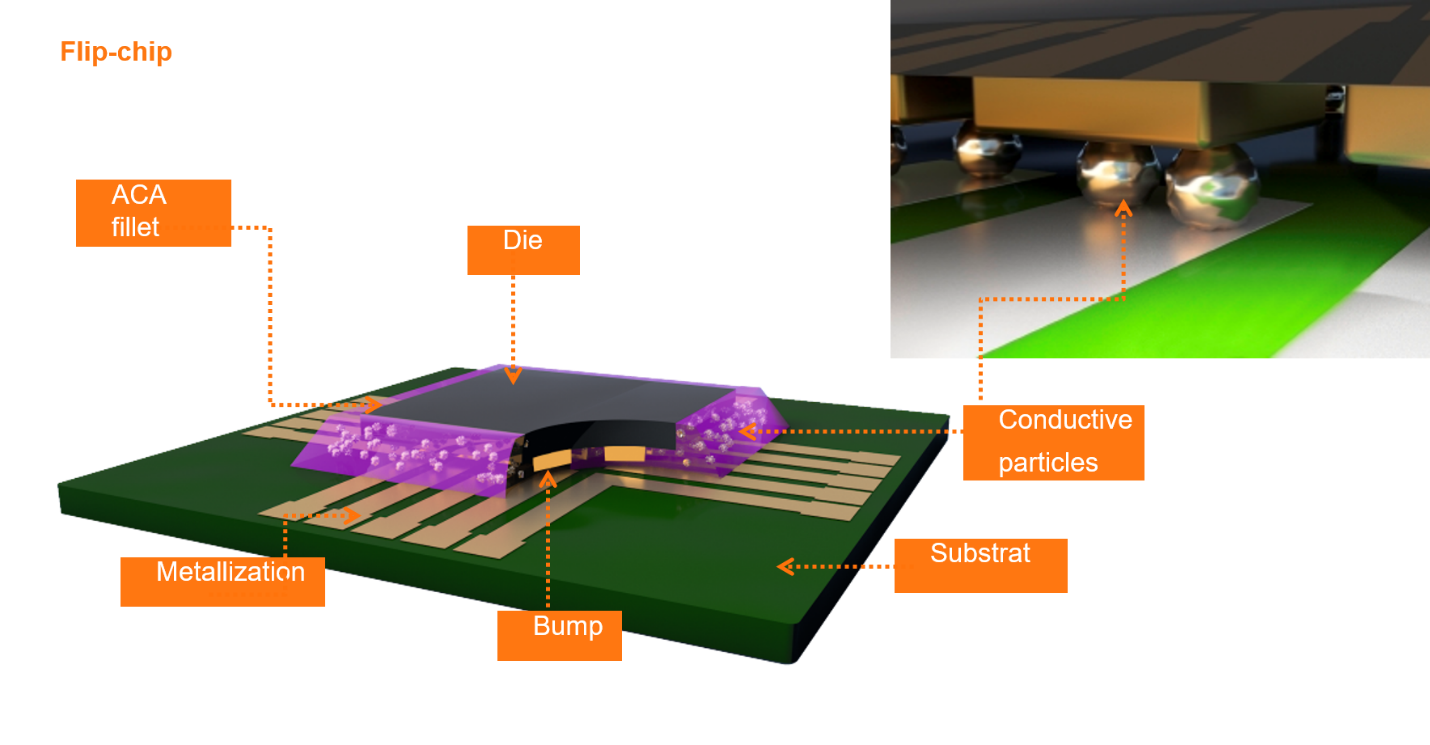

See moreAdhesive for chip RFID in the smart card

- DELO is the world's leading manufacturer of RFID adhesives. Approximately 80% of RFID tags globally contain a drop of DELO adhesive. Depending on the process, anisotropic conductive (ACA) or non-conductive (NCA) adhesives are used to bond the chips.

- See more

ICA, ACA and TCA adhesives: Classification and applications

Distinguish between isotropic conductive adhesives ICA, anisotropic conductive adhesives (ACA), and thermally conductive adhesives TCA and typical applications.

See more

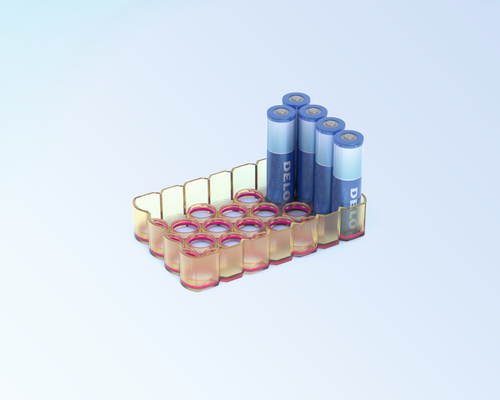

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

For high-volume applications like bonding cylindrical cells into a carrier, battery manufacturers benefit from DELO's vast portfolio of high-speed adhesives. These UV-curing ac

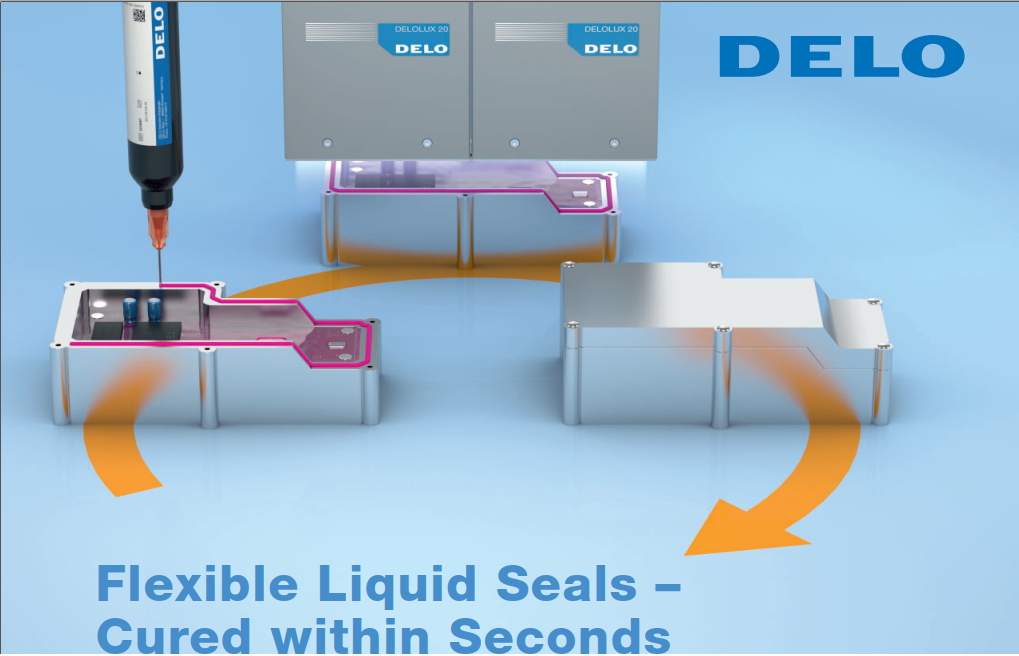

See moreDELO ADHESIVE FOR GASKETS, CURES IN JUST 3 SECONDS

DELO has developed a new light-curing liquid sealant (FIPG / CIPG = Form In Place Gasket / Cure In Place Gasket) to seal and protect the housing. These products can be easily dispersed in a liquid state directly from the glue bottle onto body parts. The adhesive will then cure within seconds under UV light. Therefore, they meet the increasing requirements for shortening production time and automating easily.

See more