Introduce:

- A glue that is compatible with both heat and UV curing methods;

- Ingredients: double curing modified polycarbamine acid derivative, 1-component glue, solvent-free;

- Especially for quick fixation of components that need to be cured at low temperature;

- Cured products are generally used in the temperature range of -40°C to +130°C; depending on the application, other limits may be more reasonable;

- Complies with RoHS directive 2015/863/EU;

- Halogen-free according to the criteria of IEC 61249-2-21;

- Compliant VOC content limit according to GB33372-202 criteria.

Photo of actual glue bottle (Photo HUST)

Application:

- Applied in many fields, especially the production of electronic components, microchips, electrical engineering, telephones... used for quick fixation of components after irradiation, bringing high durability.

- Glue is manufactured to be ready to use, if stored in cold storage, the glue needs to wait to room temperature before use. For 10 ml glue vial is 0.5h, 160ml is 2h and 600ml is 5h, no heating is allowed;

- The adhesive surface needs to be dry, clean of grease, durt, acetone, and butyl diglycol acetate can be used to clean the surface. Do not use ethanol or water to clean the surface.

- The glue should be placed in the specialized adhesive dispensing system DELOMAT 100.

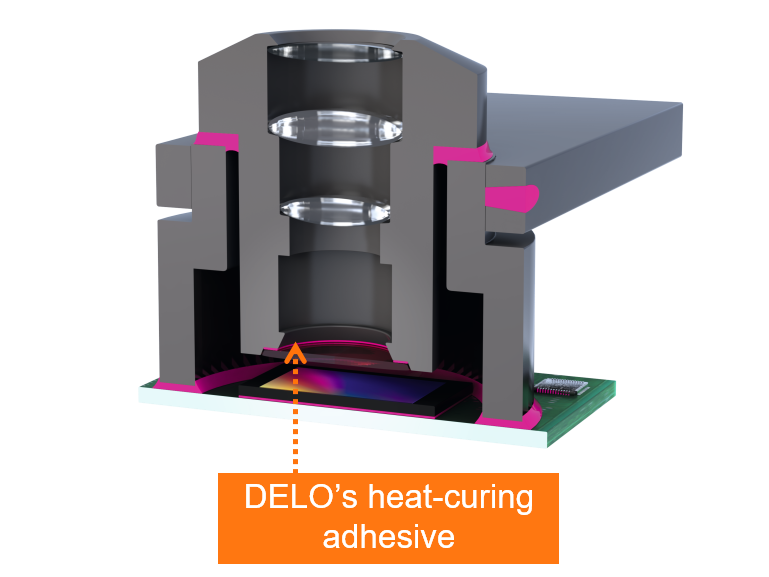

The application of gluing the lens to the barrel for the camera module (Photo DELO)

Curing:

- Pre-fixation to UVA light in the wavelength range 320 - 400 nm from 1 - 5 seconds; time to fix the joint does not exceed 1h, it is required to cure by heat at a temperature from +80 ° C to + 130 ° C.

- Refer to the standard wavelength range of DELOLUX lamps:

Lamp Type | DELOLUX 20/50/80 | ||

Wavelength Range (nm) | 365 | 400 | 460 |

Suitability | ++ | + | - |

Note: ++ particularly suitable, + suitable, - not suitable

Irradiation time (55-60 mW/cm 2 ) | 1-5s | ||

Drying time (in forced drying oven) | 80 o C | 90 o C | 100oC |

30 min | 20 min | 10 min | |

Specifications:

Color (1.0 mm thick glue): | Black, opaque | ||

Density: | 1.2 g/cm3 | ||

Viscosity (at 23 o C, Rheometer measurement, slip rate 10 s -1, gap 500µm): | 16000 mPas | ||

Glue surface after curing | Hard dry | ||

Compression shear strength (MPa) | glass/glass | 16 MPa | |

Al/Al | 12 MPa | ||

PBT/PBT | 14 MPa | ||

PC/ABS | 27 MPa | ||

PETP/PETP | 11 MPa | ||

FR4/FR4 | 30 MPa | ||

Tensile shear strength: | 11 MPa | ||

Elongation at tear: | 5 % | ||

Young's modulus: | 400 MPa | ||

Shore D hardness: | 38 | ||

Glass transition temperature: | 75 0 C | ||

Coefficient of thermal expansion CTE | in the range 30~70 0 C: | 115 ppm/K | |

in the range 80~160 0 C: | 182 ppm/K | ||

Shrinkage: | 2,4 %vol. | ||

Water Absorption: | 0,5 %wt. | ||

Processing time (at 25 o C): | 72h | ||

Storage time: | 6 months, stored at | ||

Contact HUST Vietnam for more detailed information.

HUST Vietnam is proud to be the exclusive distributor of glue, dispensing equipment, UV glue curing lamps, and technology transfer from DELO in Vietnam!