Introduce:

- As a glue compatible with both heat and UV curing, it has low air release, low shrinkage, and low CTE;

- Ingredients: modified epoxy resin, 1-component glue, solvent-free;

- High viscosity, catalytic properties (Thixotropy);

- Used for bonding between materials such as metal, glass, plastic as well as casting, fixing, or mounting around electronic components;

- Operating temperature: -40 0 C ~ 150 0 C, depending on the application;

- RoHS compliant 2015/863/EU, Halogen-free according to IEC 61249-2-21;

- Meets the VOC limit for adhesives according to the GB33372-2020 regulation.

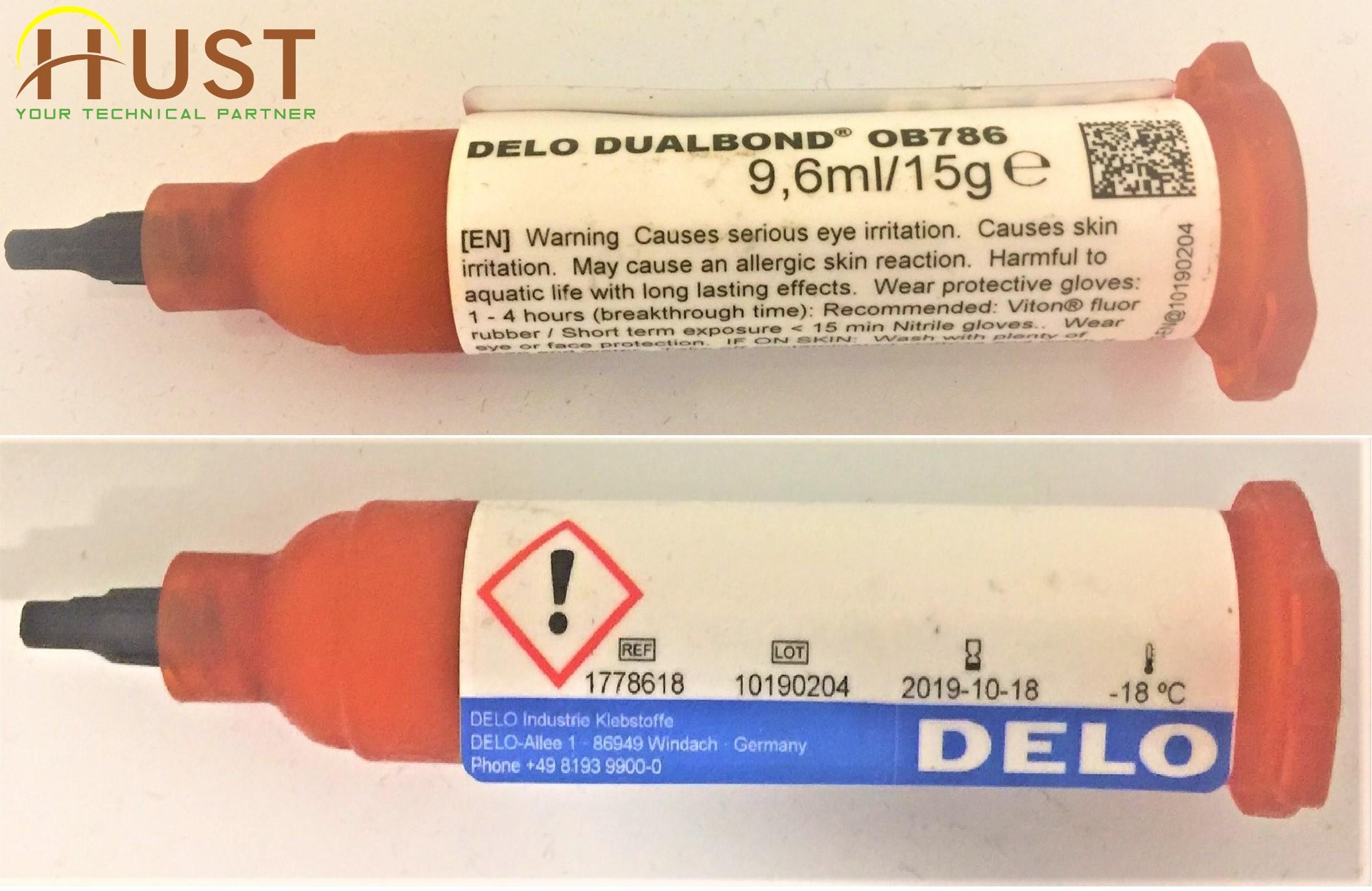

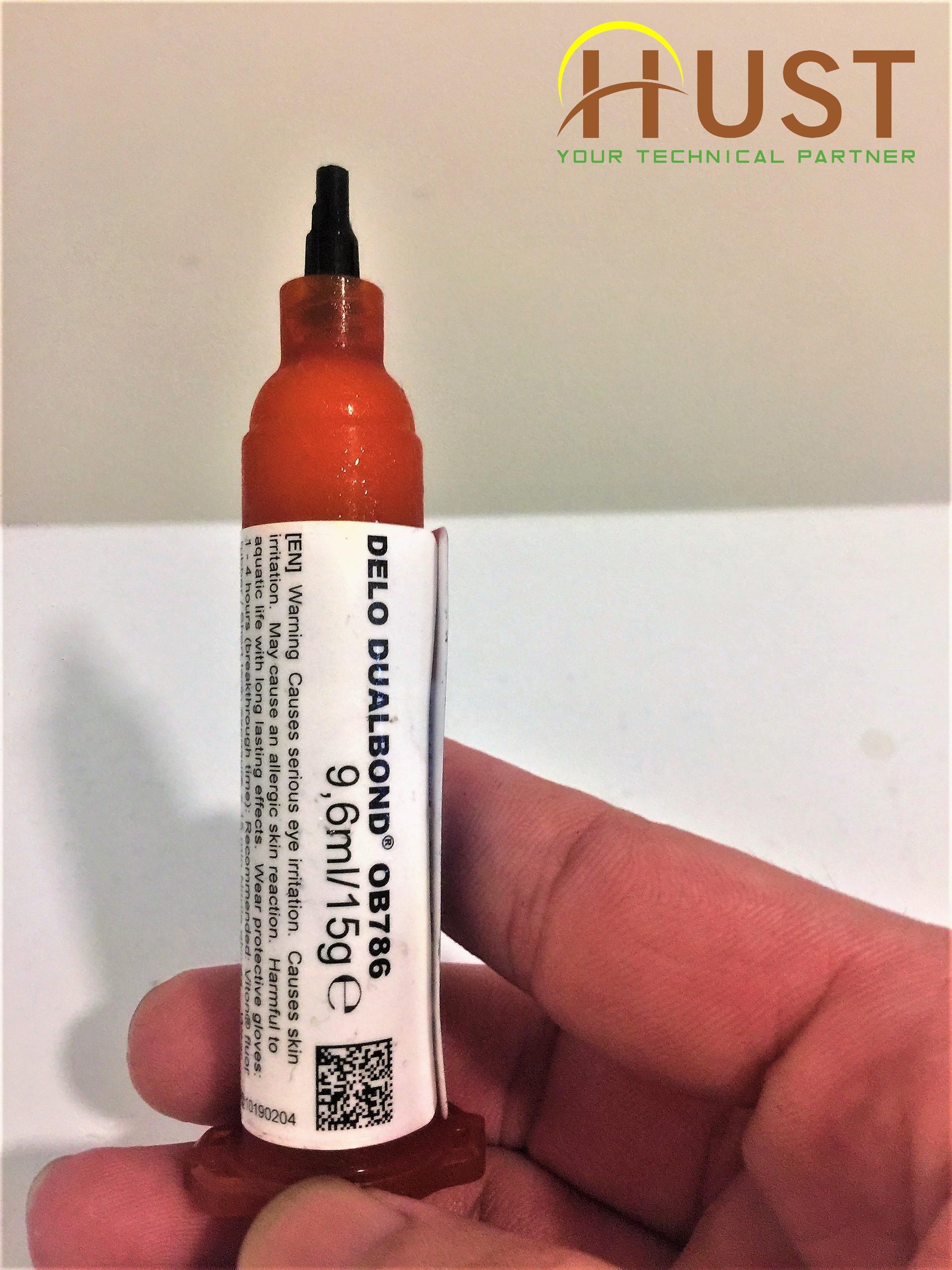

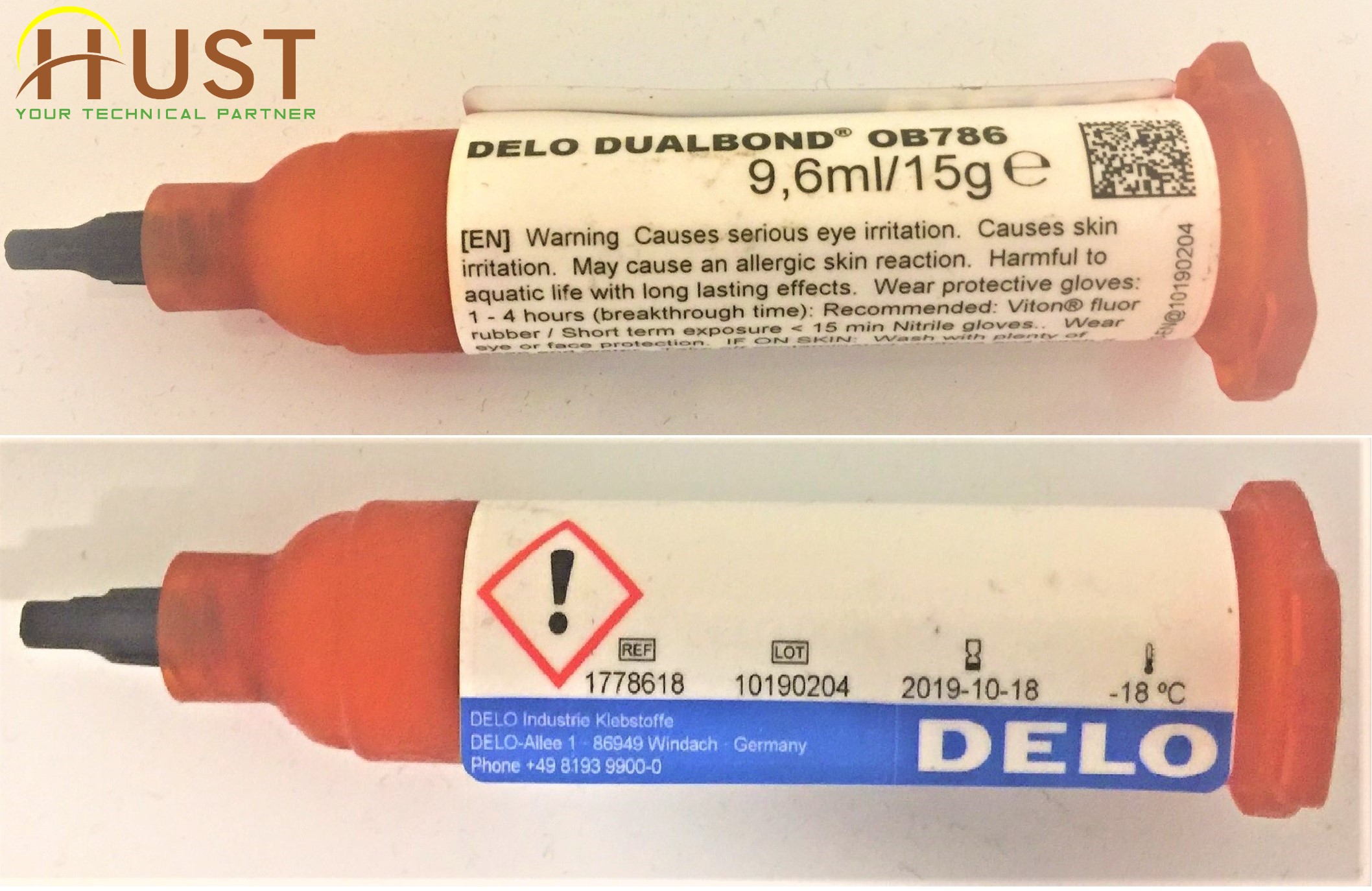

Actual photo of DUALBOND OB786 glue bottle (HUST photo)

Application:

- Applied in many fields, especially the production of electronic components, microchips, electrical engineering, telephones... used to quickly fix components after irradiation, bringing high durability.

- In order to use the adhesive effectively, it is recommended to place the glue in the DELO special dispersant, the surface to be bonded should be clean, dry, free of dust or grease.

- For a clean and well-activated surface, use the DELOTHEN surface cleaner.

- Use DELOTHEN EP for more cleaning on glass surfaces.

- Use the DELOMAT 100 gluing system and G30 or higher dispensing needle.

Curing:

- Using a UV lamp with a wavelength of 365nm. In the shadowed area, the glue can be heat dried in the range of 80~130 0 C. Both of the above methods can be used independently.

- Refer to the standard wavelength range of DELOLUX 20/50/80 lamps:

Lamp Type | DELOLUX 20/50/80 | |||

Wavelength Range (nm) | 365 | 400 | 460 | |

Suitability | ++ | - | - | |

Irradiation time (150 mW/cm 2 , 365nm) | 4 s | |||

Drying time in the air convection oven | 80 o C | 100oC | 130oC | |

50 min | 25 min | 10 min | ||

Note: ++ particularly suitable, + suitable, - not suitable

Specifications:

Color (in 1.0 mm layer thickness glue): | yellow, translucent | ||

Density: | 1.6 g/cm3 | ||

Viscosity (Rheometer | Shear rate: 10 1/s | Gap: 500 µm): | 32000 mPas | ||

Thixotropy index: | 7 | ||

Filler particles type: | Inorganic minerals | ||

Filler particles size: | d95 = 12 µm | ||

Filler particles content: | 55 %wt. | ||

Maximum adhesive layer that can be cured: | 0,76 mm | ||

Glue surface after curing: | Hard dry | ||

Compression shear strength (MPa) | Al/Al (anodized) | 41 MPa | |

FR4/FR4 | 27 MPa | ||

Glass/glass | 20 MPa | ||

PPS/PPS | 33 MPa | ||

Tensile strength: | 41 MPa | ||

Elongation at tear: | 0,8 % | ||

Young's modulus: | 7500 MPa | ||

Shore D hardness: | >90 | ||

Glass transition temperature: | 1790C | ||

Coefficient of thermal expansion CTE | in the range 30~80 0 C: | 38 ppm/K | |

in the range 130~150 0 C: | 53 ppm/K | ||

Shrinkage: | 1,6 %vol. | ||

Water Absorption: | 0,08 %wt. | ||

Processing time (at 25 o C): | 30 days | ||

Storage time: | 6 months, stored at -45 ~ -15 0 C with the unopened container. | ||

Contact HUST Vietnam for more detailed information.

HUST Vietnam is proud to be the exclusive distributor of glue, dispensing equipment, UV glue curing lamps, and technology transfer from DELO in Vietnam!