Introduce

DELO has developed DELO DUALBOND BS3770 adhesive, a special electronics adhesive for semiconductor manufacturers to meet the rigorous quality and reliability tests of car manufacturers.

It is a modified polycarbamin acid derivate, free of solvents, 1C, light-fixable, heat-curing mandatory, tension-equalizing, thixotropic, and reflow-resistant.

Special features of the product:

▪ Halogen-free according to IEC 61249-2-21.

▪ Meets RoHS 2015/863 / EU standards.

▪ Usage temperature range: from -40 ~ 150 oC.

Featured application:

- Bonding gaps and die-attaches in LiDAR and RADAR sensors in ADAS systems on today's smart cars,...

- BS3770 is a solution for housing and filter sealing that meets the more stringent requirements, withstanding the automotive industry's testing, to AEC-Q100 standard.

- The BS3770 is an optimized adhesive for applications that need a stacky period (B stage) while assembling other parts together before final curing such as die attach in the electronic factor.

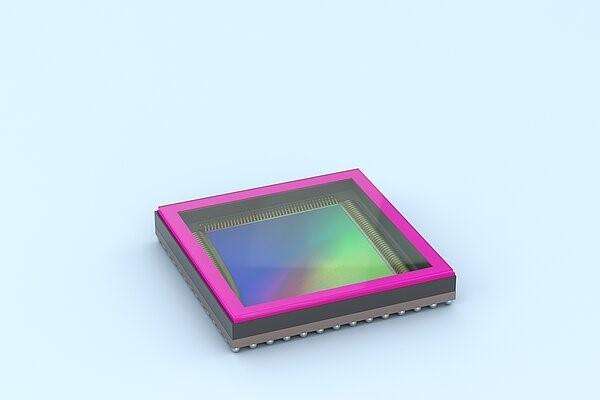

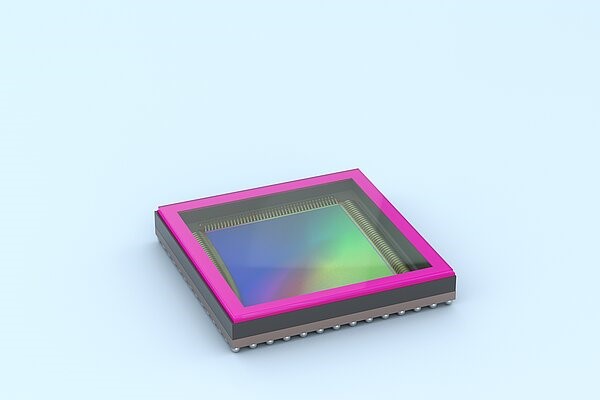

DELO DUALBOND BS3770 connects the sensor housing and filter glass in an airtight manner, ensuring the uninterrupted functionality of the image sensors. (Photo: DELO)

Specifications:

Curing: | |

- Compatible LED lights: | LED 365 nm, LED 400 nm |

- Fixed by UV light | 200 mW/cm2, LED 400nm, 10s. |

- Cure in an air-convection oven | at 150 oC, for 40 minutes. |

Technical parameters: | Use contact dispensing needles, screen printing, inkjet printing or non-contact dispensing valves. |

- Condition time (at +23 °C / 50% r. h) | 0.5 h for 10ml glue bottle |

- Processing time (at +23 °C / 50% r.h) | : 3 days |

- Period of sticky state (at +23 °C / 50% r. h) | : 21 days |

- Storage time (at-18 °C) | : 06 months |

Technical properties: | |

- Color in an uncured condition | : Beige, opaque |

- Color in cured condition in 1 mm layer thickness | : Beige, opaque |

- Density | : 1.0 g/ cm3 |

- Viscosity | : 115,000 mPas |

- Thixotropy index ( liquid | Rheometer | Gap: 500 µm) | : 3.2 |

- Die shear strength (DELO Standard 30 | Si | Chip 2 mm x 2 mm | Ag | 150 °C | 40 min) | : 18 N |

- Die shear strength (DELO Standard 30 | Si | Chip 2 mm x 2 mm | Solder resist | Lead frame 50 mm x 25 mm | Pretreatment: Annealing | 400 nm | 200 mW/cm² | 10 s | Plus | 150 °C | 40 min) | : 15 N |

- Die shear strength (DELO Standard 30 | Si | Chip 2 mm x 2 mm | Solder resist | Lead frame 50 mm x 25 mm | Pretreatment: Annealing | 150 °C | 40 min) | : 18 N |

- Tensile (according to DIN EN ISO 527 | 150 °C | 40 min) | : 2 MPa |

- Elongation at tear (DIN EN ISO 527) | : 200% |

- Young's modulus (Rheometer | 400 nm | 200 mW/cm² | 10 s | Plus | 150 °C | 40 min) | : 2 MPa |

- Young's modulus (DELO Standard 54 | Rheometer | 150 °C | 40 min) | : 5 MPa |

- Shore A hardness (according to DIN EN ISO 868 | 150 °C | 40 min) | : 37 |

- Glass transition temperature | : -57 oC |

- Coefficient of linear expansion | : 83 ppm/K |

- Coefficient of linear expansion | : 253 ppm/K |

- Shrinkage (150 °C | 40 min) | : 0.38 vol. % |

Download TDS here: https://www.delo-adhesives.com/service-center/downloads/downloads/datasheet/DELO%20DUALBOND_BS3770_TIDB-en.pdf?type=5001

Contact HUST Vietnam for more detailed product information!