DELO adhesive for autonomous driving technology

14:48 - 20/04/2023

Automated driving (Level 3) is considered technically possible thanks to high-performance driver assistance systems (ADAS) and also thanks to innovations in adhesive technology.

Adhesives for cameras and LiDAR sensors;

Adhesives for radar and ultrasonic sensors;

Adhesives and sealants for control devices and plugs.

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

DELO adhesive for autonomous driving technology

The auto industry has made great progress in autonomous driving, especially in well-controlled environments such as on the highway. Automated driving (Level 3) is considered technically possible thanks to high-performance driver assistance systems ( ADAS ) and also thanks to innovations in adhesive technology. Adhesives play a small, but crucial part in the future of autonomous driving technology.

More and more sensors are mounted on cars to assist the driver (Photo DELO)

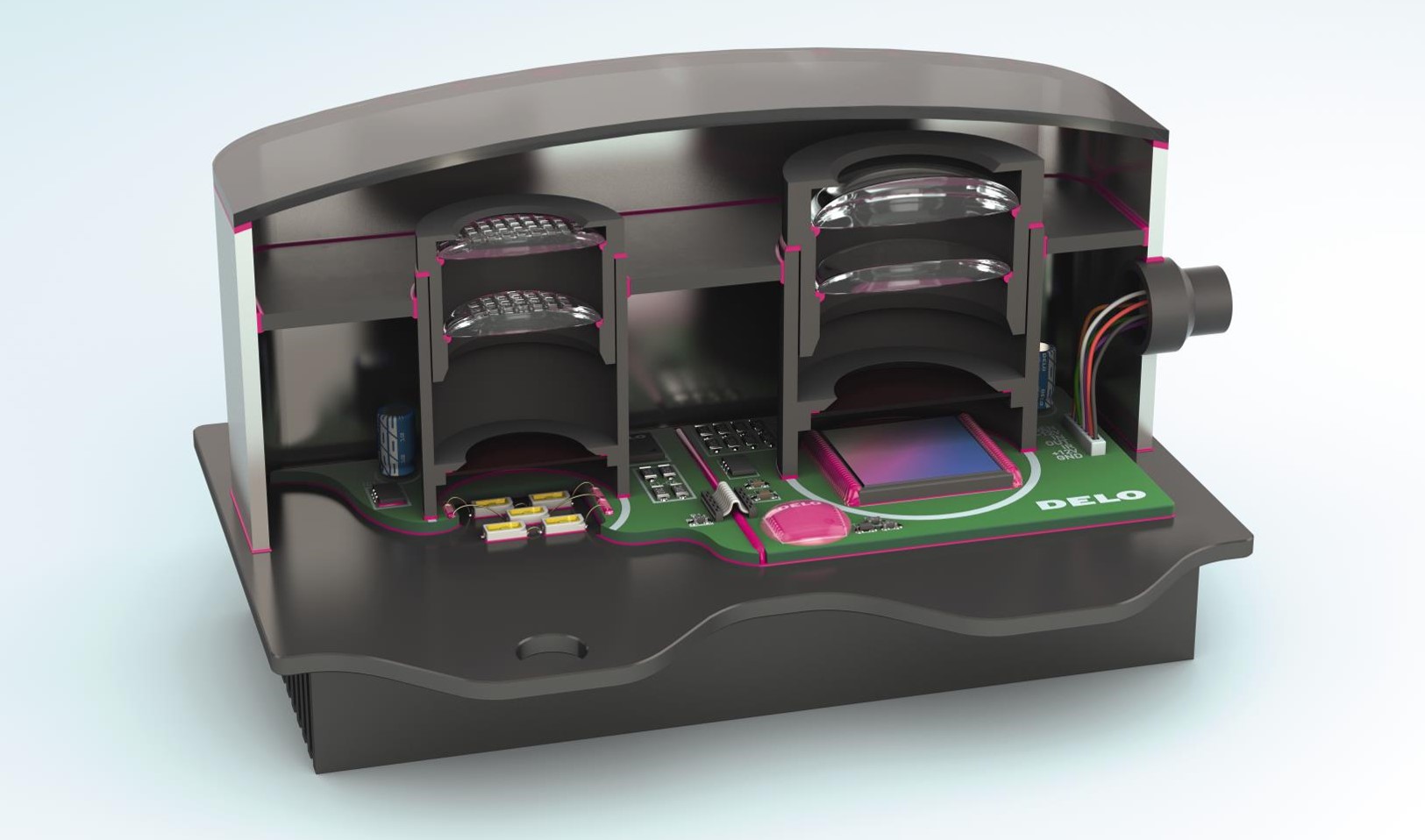

Glue for cameras and sensors LiDAR

Adhesives play a particularly important role in cameras. In autonomous driving technology, cameras are used for traffic sign recognition, lane keeping, and collision warning assist systems even in mid-range cars. In this case, as with the increasingly popular LiDAR sensors in the luxury product line, the associated components, including lenses, filters, and image sensors, must operate reliably over time. long time. Low air release and low shrinkage and reproducibility of the adhesive are crucial for this prerequisite.

Even more important to the optical system is that the lens position does not change after manufacturing. Users can use UV-fixing glues to ensure this. As a result, the optics of the camera modules can be dynamically aligned and "frozen". Therefore, in the subsequent processing, the lens is guaranteed not to slip. During subsequent heat treatment, the adhesive will achieve its optimum properties.

DELO glue used in LiDAR sensors (Photo DELO)

DELO has a wide portfolio of adhesives with different chemicals to provide optimal solutions for different adhesive areas and material combinations for LiDAR cameras and sensors. They meet all optical and mechanical requirements even under the most adverse conditions, from direct sunlight under the windshield to outdoors with seasonally fluctuating temperatures, as well as rain, snow, and ice. Furthermore, especially the double curing option, they allow for short cycle times and thus increase the production efficiency.

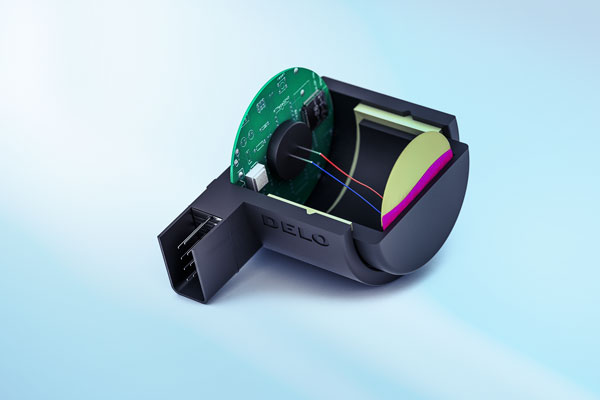

Adhesives for radar and ultrasonic sensors

DELO glue used in ultrasonic sensors (Photo DELO)

Similar to radar and ultrasonic sensors, adhesives often have to perform other functions than their mechanical duties. Take ultrasonic sensors as an example, where the adhesive helps ensure that the sensor transmits a high-quality ultrasonic signal and does not distort it. To ensure this, the adhesive must have good acoustic properties and suitable vibration characteristics.

The photocuring epoxy adhesives in the DELO KATIOBOND range meet these requirements exactly, even in the service temperature range of –40 °C to +120 °C, and pass all required salt spray tests.

Other highlights: They accommodate on-line processes as well as short cycle times in mass production.

Some adhesives can trigger a pre-cure reaction which ensures reliable drying even in obscured areas and requires only one process step.

Adhesives and sealants for control devices and plugs

Control chips for motors or electronics on PCB boards must be protected from moisture, the environment, and corrosion, even under extreme temperatures. Therefore, the most important task for adhesives and sealants is the long-term protection of control box covers, plugs, and other micro-switches in cars. Another typical application is temperature control for power electronic circuits. For example, in air conditioning systems, thermally conductive adhesives ensure that heat generated by the load is quickly dissipated to the radiator.

Many DELO adhesives and sealants are developed specifically for these applications and for some of their special requirements, such as adhesion to certain surface coatings. They provide the necessary reliability while allowing efficient improvement of manufacturing processes thanks to adhesives that cure or completely fix in seconds and allow tightness testing on the wire. pass.

DELO glue used in microswitch plugs (Photo DELO)

DELO adhesive properties / mechanical properties:

- The sealing effect is very good;

- Good resistance to temperature test and solvent resistance;

- Fast curing;

- On-line tightness testing.

Source: DELO ( https://www.delo-adhesives.com/us/products/automotive-industry/automated-mobility )

HUST Vietnam - The exclusive distributor of DELO's adhesives and dispensing technologies, and curing machine in Vietnam.