Introduce:

- It is a UV curing, high viscosity acrylate adhesive, suitable for bonding a variety of materials such as glass, PC plastic, PMMA, PA6, PBT, aluminum, stainless steel, etc. …;

- Resistant to humidity;

- Ingredients: modified acrylate, one-component glue, solvent-free, thixotropic;

- Compliant RoHS standard 2015/863/EU;

- Achieve certified biosafety standards USP 23, 1995, Class VI Plastics -70 ° C.

Application:

- The application is especially suitable when attaching glass parts to metal;

- UV curing ability in the range from 320 nm to 420 nm;

- Operating temperature: -40 0 C ~ 120 0 C, depending on the application.

Some applications using PHOTOBOND 4468 glue:

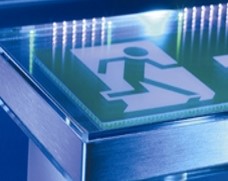

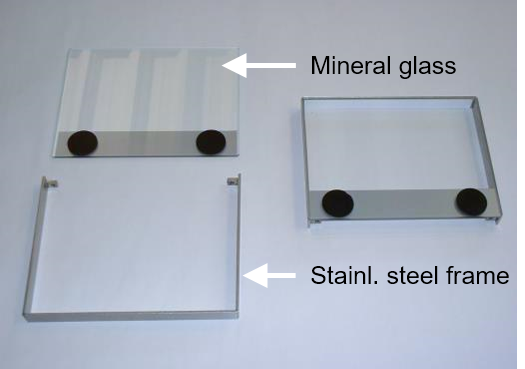

- Bonding the frames of the emergency exit LED sign

|  |

Adhere the frames of the emergency exit LED sign with PHOTOBOND 4468 (Photo DELO) | |

Material Composition:

- Frame: Honed or sandblasted stainless steel

- Glass plate: tempered glass

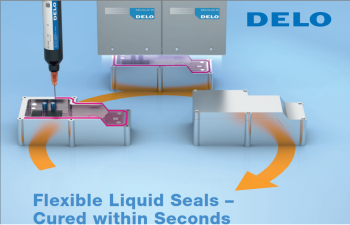

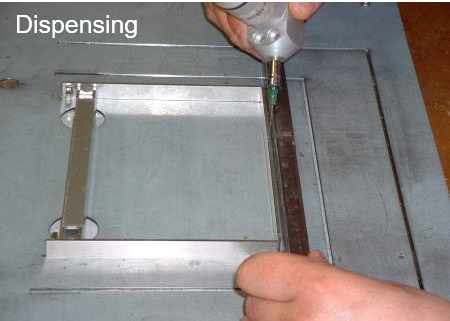

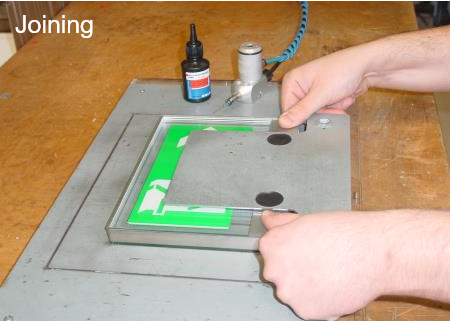

Implementation process:

|  |  |

Dispensing | Joining | UV irradiation curring |

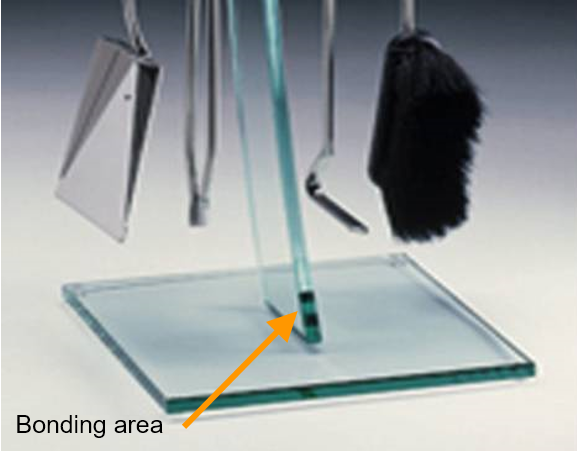

- Bond the pieces of glass into a multi-tool holder

|

Material Composition: TSG tempered safety glass, thickness: 10mm |

Bond the glass pieces to the mount with PHOTOBOND 4468 (Photo DELO) | |

Required and tested adhesive properties

- Viscosity: Can be dispensed easily;

- Mechanic: Tension-equalizing so that cracking is avoided and sidewise impact load can be compensated;

- Process: Easy, one-component processing and fast curing in seconds with light;

- Good adhesion to the materials.

Required, passed suitability tests

- Temperature/climate: -20 to +80 °C;

- Sidewise drop test onto the tiled floor;

- Loading test with fire irons (several kg);

- Bending stress of the holder.

Curing:

- Minimum UV curing time:

+ 40 s with UV lamp – irradiation intensity 60 mW/cm 2

+ 24 s with LED – irradiation intensity 200 mW/cm 2

- DELOLUX 20/50/80 lamps with wavelengths of 365 nm and 400 nm are both suitable for use with PHOTOBOND 4468 glue. Increasing the light intensity will shorten the irradiation time and conversely, reducing the light intensity will prolong the drying process.

Specifications:

Visible inspection: | ||

- Color (with glue thickness from 0.1 ~ 1.0 mm): | Transparent, colorless | |

- Viscosity: | 7000 mPas | |

- Density: | 1.02 g/cm3 | |

Mechanical strength: | ||

- Compression shear strength: (MPa) (According to DELO Standard 5 UV irradiation intensity 60 mW/cm² for 60 s) | Glass/Al | 21 MPa |

Glass/Stainless steel | 20 MPa | |

Glass/Glass | 20 MPa | |

- Tensile strength (Based on DIN EN ISO 527 | 400 nm | 200 mW/cm² | 60 s): | 14 MPa | |

- Elongation at break: | 200% | |

- Young's modulus (400 nm, 200 mW/cm 2, 60s): | 700 MPa | |

Physical properties: | ||

- Hardness Shore D: | 50 | |

- Glass transition temperature: | 580C | |

- Coefficient of thermal expansion: (According to DELO Standard 26 | TMA | Survey at: T: 30 °C - 150 °C | 400 nm | 200 mW/cm² | 60 s) | 210 ppm/K | |

- Shrinkage: | 8,6 % | |

- Water absorption: | 1,0 % | |

- Refractive index: | 1,5 | |

- Creep resistor CTI (According to VDE standard 0303-1) | 600 M | |

- Shelf life: (Stored at 0 ~ 25 0 C with the unopened container) (Time from when the customer receives the goods) | 6 months,. | |

For more detailed information, please contact us.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing and curing systems, and technology transfer from DELO in Vietnam!