Introduce:

- A modified acrylate adhesive, 1-component, solvent-free, UV-curable, low-viscosity, suitable for bonding a wide range of materials such as glass, stainless steel, and PC, PBT plastics,…

- Compliant RoHS standard 2015/863/EU.

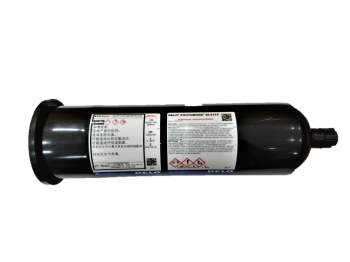

Actual photo of sample glue bottle PHOTOBOND GB368 (GB = Glass Bonding)

Application:

- The application is especially suitable for bonding layers of glass, furniture, decorative glass, building glass walls, etc. After curing, the adhesive has a dry, firm surface.

- UV curing ability in the range from 320 nm to 420 nm;

- Operating temperature: -40 0 C ~ 120 0 C, depending on the application.

Some applications using PHOTOBOND GB368 glue:

- Construction of the facade of the Crystal House building

MVRDV has designed many famous projects in the world. Crystal House is one of those famous buildings. With creativity, combining the use of Poesia (Italy) glass bricks with DELO glue, the engineers have successfully built the Crystal House building in Amsterdam, the Netherlands.

|

The facade of the Crystal House building (Photo DELO) |

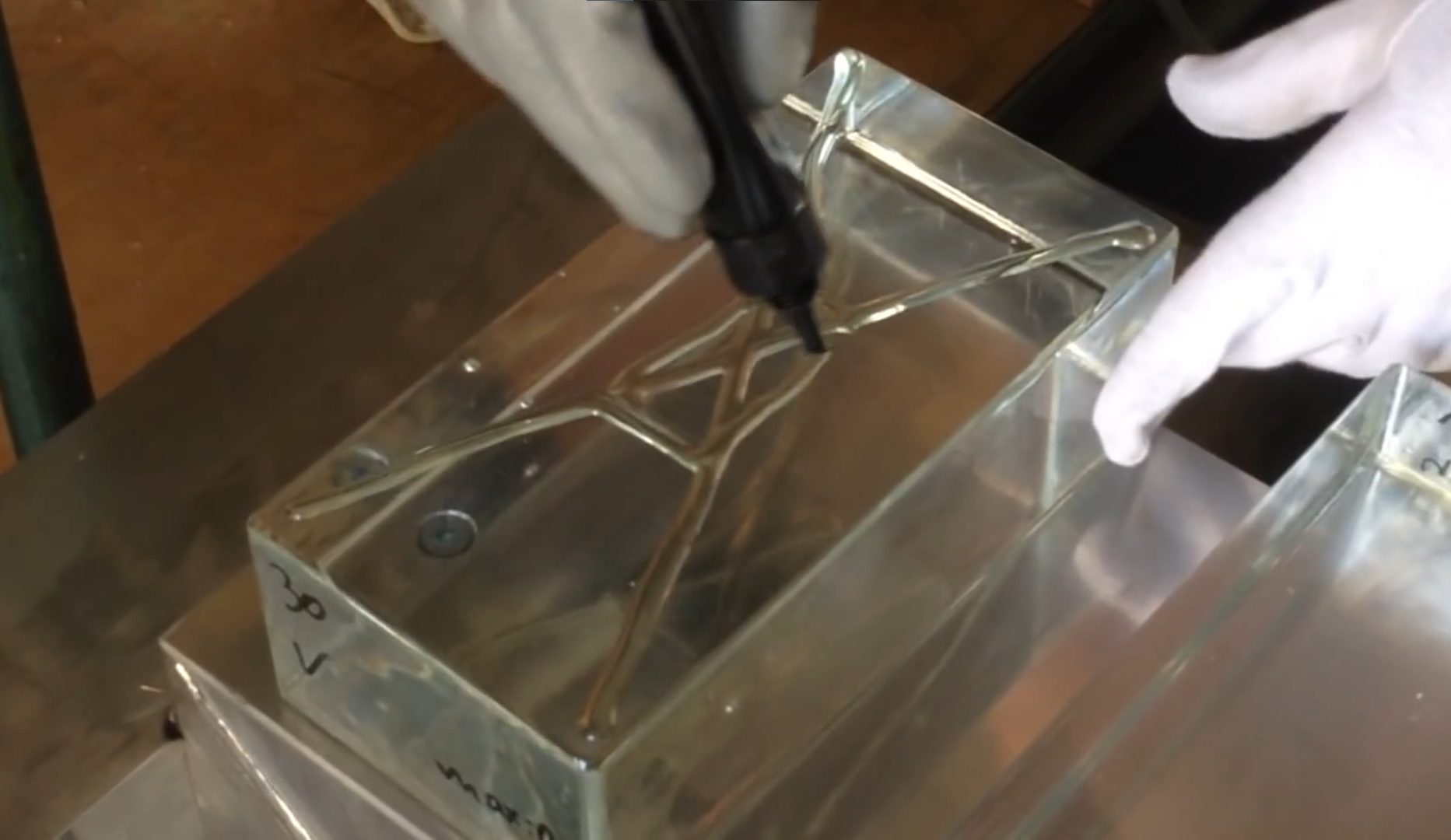

Material composition: Glass bricks of Poesia (Italy)

Basic steps:

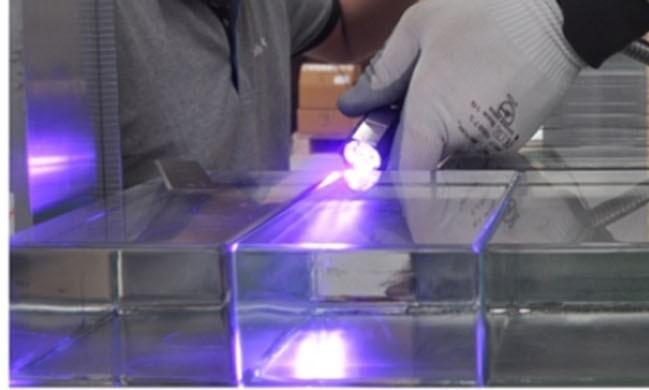

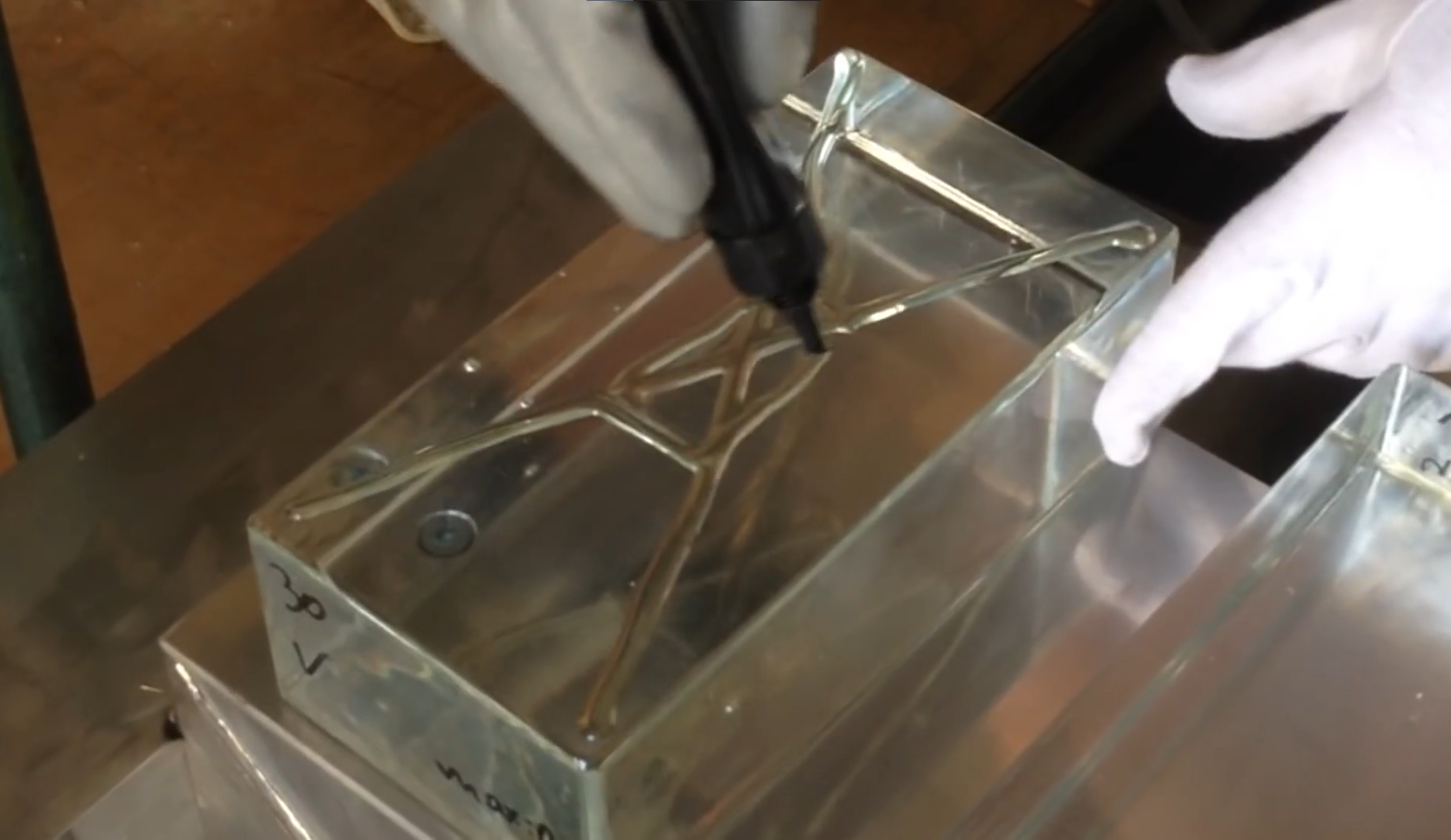

|  |  |

Choose and sort bricks | Apply glue and alignment | UV irradiation to cure the glue |

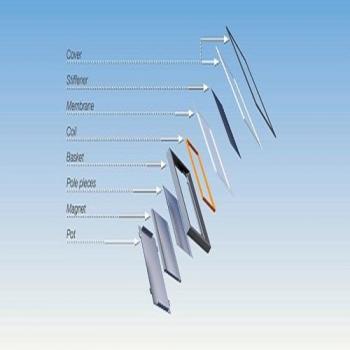

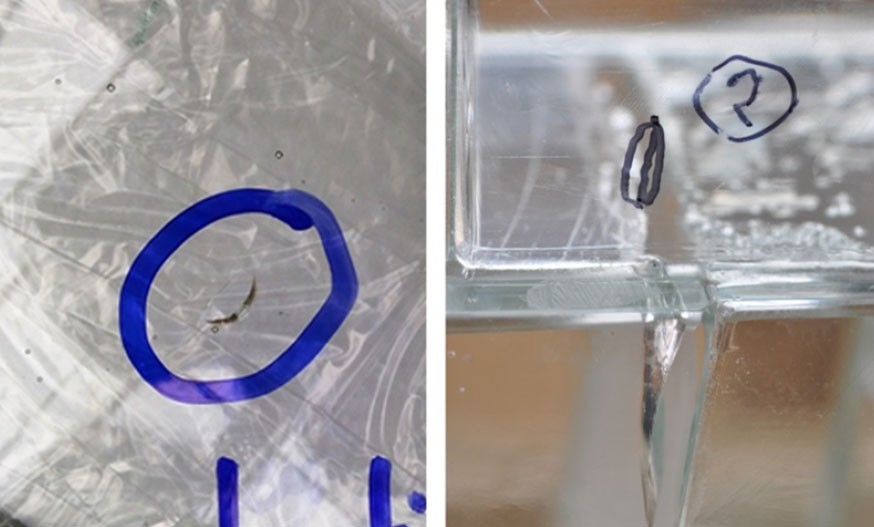

- Bonding the electronic circuit to the LEDs inside the LED

Material Composition:

Glue meets the following standards: - Electrical Safety Regulation (UNE EN 60730-2) - Water tightness (UNE 20324 EN 60529) - Mechanical action (UNE-EN 50102) - Meet design requirements thanks to transparency. Tests: - Mechanical impact: UNE-EN 50102 standard: Class IK10 - energy absorption 20 J, weighs 5 kg falling from a height of 0.4 meters (5 times); - Watertightness: Standard UNE 20324 EN 60529 Grade IP68: 2 meters underwater for one day; | |

Bonding the electronic circuit to the LEDs inside the LED with PHOTOBOND GB368 glue (DELO photo) | |

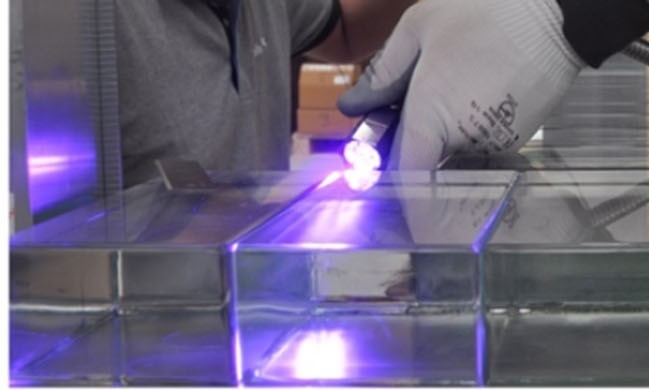

Curing:

- Minimum curing time by UV light: 15 s with UV lamp – light intensity 60 mW/cm 2

- DELOLUX lamps with both wavelengths of 365 nm and 400 nm are suitable for use with PHOTOBOND GB368 glue.

- Increasing the irradiation intensity will shorten the curing time and conversely, and reverse.

Specifications:

Visible inspection: | ||

- Color (with glue thickness from 0.1 ~ 1.0 mm): | transparent, colorless | |

- Viscosity: | 5700 mPas | |

- Density: | 1.0 g/cm3 | |

Mechanical strength: | ||

- Compression shear strength (MPa) (According to DELO Standard 5, UV irradiation intensity 60 mW/cm² for 60 s) | Glass/PMMA | 21 MPa |

PC/Al | 20 MPa | |

PC/Glass | 20 MPa | |

PC/PC | 6 MPa | |

PMMA / PMMA | 15 MPa | |

Glass/Glass | 23 MPa | |

Glass/Al | 23 MPa | |

Glass/ABS | 15 MPa | |

- Tensile strength (Based on DIN EN ISO 527 | 400 nm | 60 mW/cm² | 90 s): | 20 MPa | |

- Elongation at tear: | 17% | |

- Young's modulus (400 nm, 200mW/cm 2, 60 s): | 900 MPa | |

Physical properties: | ||

- Hardness Shore D: | 65 | |

- Glass transition temperature: | 1020C | |

- Coefficient of thermal expansion: (Base on DELO Standard 26 | TMA) | 236 ppm/K | |

- Shrinkage: | 7,0 % | |

- Water absorption: | 0,5 % | |

- Refractive index: | 1,506 | |

- Decomposition temperature: | 230 oC | |

- Shelf life: (Time calculated from when the customer receives the goods) | 12 months, stored at 0 ~ 25 0 C with the unopened container. | |

For more detailed information, please contact us.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing and curing systems, and technology transfer from DELO in Vietnam!