Introduce:

- This is a type of acrylate glue that can be cured by UV and light, high viscosity, suitable for bonding a variety of materials such as glass, PC plastic, PMMA, PA6, PBT, etc;

- Components: modified acrylate, 1-component adhesive, solvent-free, and thixotropic;

- Compliant RoHS standard 2015/863/EU;

- Passed UL 94 HB test standards by independent metrology institutes.

PHOTOBOND AD494 glue with different bottle volumes

Application:

- Applied in many fields with a variety of materials such as plastic-plastic, plastic-glass, glass-glass, metal-plastic, especially suitable when attaching glass parts to plastic frames or mounting bases glasses;

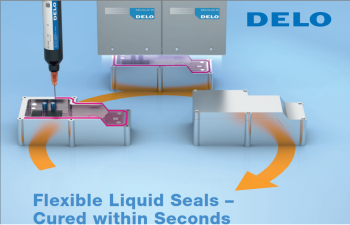

- The ability to cure both UV and visible light at the same time allows curing many components that are difficult for UV light to penetrate;

- Good elastic balance strength thanks to the high elongation at the tear characters;

- The high viscosity allows the adhesive to be as thick as 2 mm;

- Cured adhesive can be used in temperature range: -40 0 C ~ 150 0 C, depending on the application.

Some applications using PHOTOBOND AD494 glue:

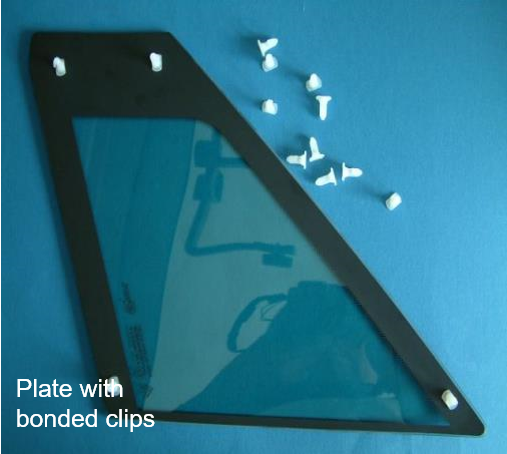

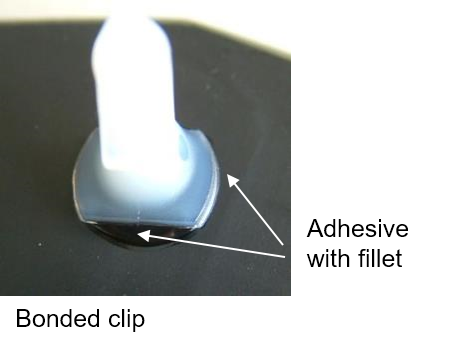

- Bond clips to the plate on the car windows

|  |

Bond the clips to the plate on the car window with PHOTOBOND AD494 glue (DELO photo) | |

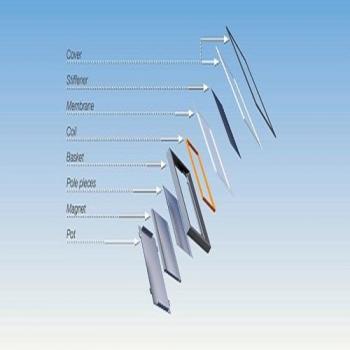

Components Material:

- Clips: PC / ABS plastic opaque or light blue

- Plate: Black Ceramic imprint material

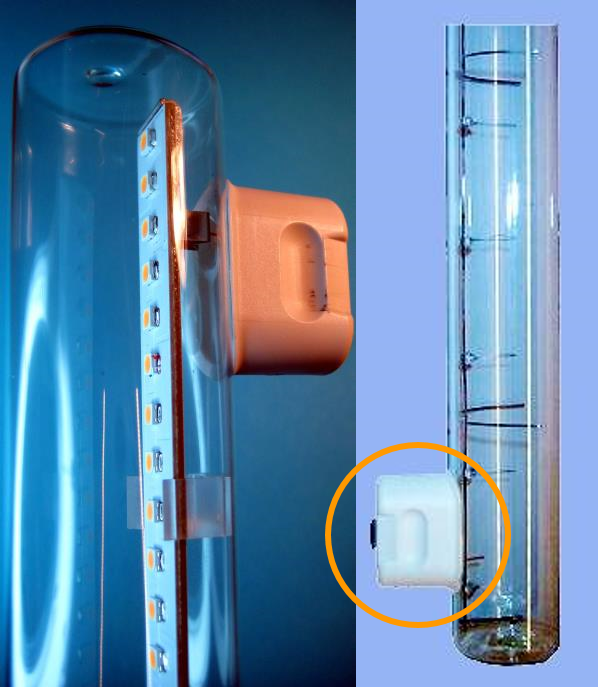

- Fix and seal the front shield on the housing of the outdoor LED light

| Component materials:

|

Fix and seal the front shield on the housing of the outdoor LED with PHOTOBOND AD494 glue (DELO photo) | |

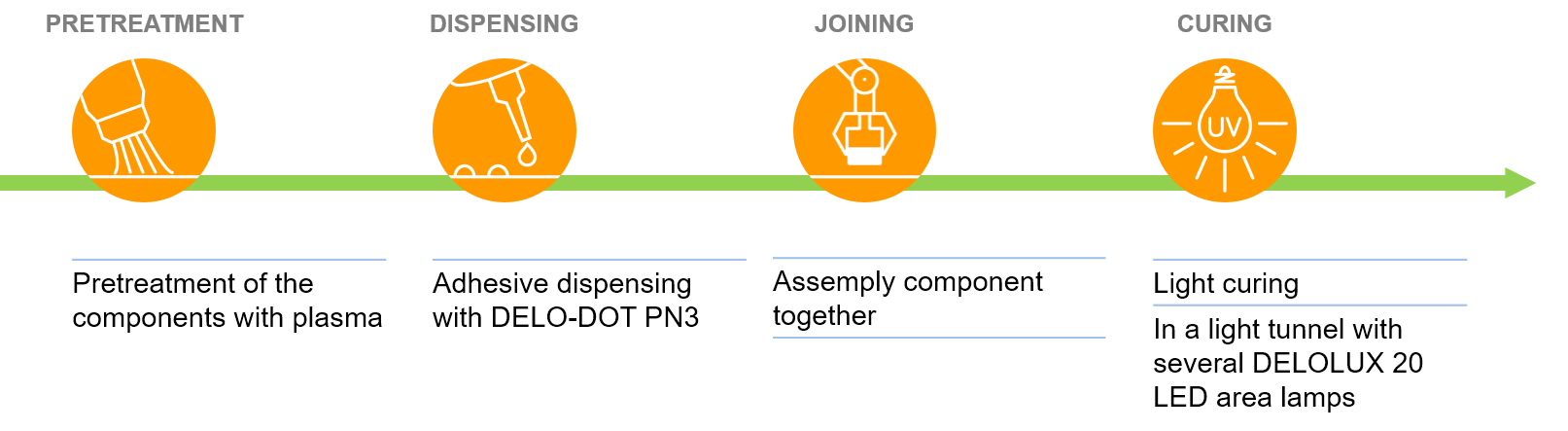

Applying process:

- Bonding of a lamp socket to a linear lamp

|  |

Attach the lamp socket to the LED tube with PHOTOBOND AD494 glue (DELO photo) | |

Component materials:

- Socket: PBT Pocan 4225

- Lamp body: Glass

Applying process:

|  |  |

| Plasma processing | Apply glue with DELO-DOT | Curing glue with DELOLUX 80 lamp |

Curring:

- Minimum UV curing time:

+ 14s with UV lamp – light intensity 60 mW/cm 2

+ 9s with LED – light intensity 200 mW/cm 2

- Use UV or visible light with a wavelength from 320~450nm. DELOLUX lamps are designed to be compatible with the AD494. Increasing the light intensity will shorten the irradiation time and conversely, decreasing the light intensity will prolong the glue drying process.

- Refer to the standard wavelength range of the DELOLUX 20/50/80. lamp

Lamp Type | DELOLUX 20/50/80 | ||

Wavelength Range (nm) | 365 | 400 | 460 |

Suitability | + | ++ | - |

Note: ++ particularly suitable, + suitable, - not suitable

Specifications:

External inspection: | ||

- Color (with glue thickness from 0.1 ~ 1.0 mm): | transparent, colorless | |

- Viscosity (at 23 °C, rheometer measurement, clearance 500 μm, cutting speed 2 1/s): | 32000 mPas | |

- Proportion: | 1.07 g/cm3 | |

Mechanical strength: | ||

- Compression shear strength (MPa) (According to DELO Standard 5, UV irradiation intensity 60 mW/cm² for 60 s) | PC/ABS | 14 MPa |

PS/PS | 10 MPa | |

PMMA/Glass | 11 MPa | |

PC/PC | 18 MPa | |

PC/PA6 | 10 MPA | |

PC/Glass | 12 MPa | |

PC/Al | 8 MPa | |

Glass/Al | 13 MPa | |

Glass/ Stainless steel | 13 MPa | |

FR4/PA6 | 9 MPa | |

- Tensile strength (Based on DIN EN ISO 527 | 400 nm | 60 mW/cm² | 90 s): | 13 MPa | |

- Elongation at tear: | 310% | |

- Young's modulus: | 30 MPa | |

Physical properties: | ||

- Hardness Shore A: | 80 | |

- Hardness Shore D: | 25 | |

- Glass transition temperature: | 480C | |

- Decomposition temperature: | 2250C | |

- Shrinkage: | 6,8 % | |

- Water absorption: | 3% | |

- Storage life: (Time from when you receive the goods) | 6 months, stored at 0 ~ 25 0 C with the unopened container | |

For more detailed information, please contact us.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing, curing systems, and technology transfer from DELO in Vietnam!