DELO adhesive is used for infrared radiation filters

13:54 - 30/09/2020

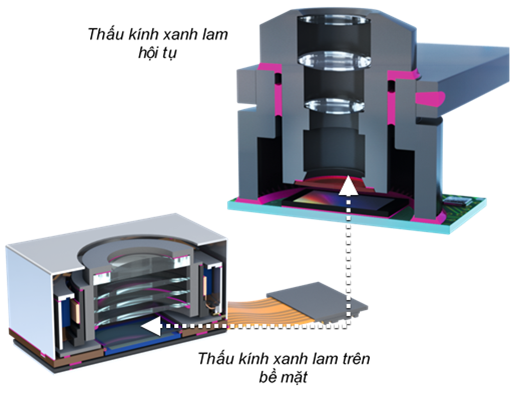

- Infrared filter lenses help to remove the infrared wavelength of sunlight, filter diffraction, protect the image sensor, and prevent the image from turning red.

- The lenses are only fixed to the frame with adhesive. Therefore, the adhesive is required to filter out more than 99% of infrared radiation.

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Introduce:

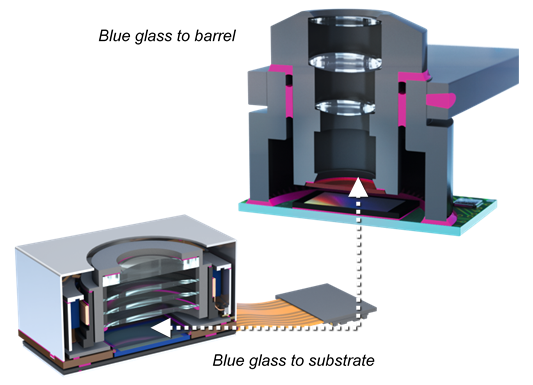

Infrared filter lenses help to remove the infrared wavelength of sunlight, filter diffraction, protect the image sensor, and prevent the image from turning red.

The lenses which are called "Blue glass lens" only fixed to the frame with adhesive. Therefore, the adhesive is required to filter out more than 99% of infrared radiation.

DELO is always at the top of the adhesive manufacturer for this application, meeting all the strictest standards of any smartphone manufacturer in the world.

The components are made from the materials include:

- Glass;

- Plastic (such as PC and LCP);

- High resistant temperature ceramic HTCC.

The recommended certain DELO adhesive lines for this case:

- DELO DUALBOND LT3411;

- DELO PHOTOBOND GB368, AD491 only curing by UV light;

- DELO DUALBOND AD425, AD465 for some special applications.

Requirements and tests to be met for the infrared filter adhesives include:

- Very short timeframe/high USP à Dispensing ~ 1.3 sec, UV prefixing ~ 0.5sec

- Flow behavior and viscosity à E. g. aspect ratio up to 0.7

- Fast / low-temperature heat curing to not affect lens or housing materials à 30 min, < +80 °C

- Insulation from lateral light à Black colored adhesive

- Drop test resistance à Passes 1.6 m drop test

- No condensation à Very low outgassing, halogen-free / RoHS-compliant

- No tilt of glass à Low shrinkage

- Moderate modulus and excellent adhesion à Suited to individual BLT

The DELO adhesives are outstanding properties that meet all of the above requirements:

- Optimized camera modulus for drop test reliability;

- Excellent adhesion to IR filters with a wide range of plastic and ceramic materials;

- Optimized flow behavior and viscosity to easy allow adjustment of dispense needle;

- Very fast curing for high production volumes;

- Curing at low temperatures < +80oC help to avoids damage of optical components and coatings;

- Fixed components by UV/ visible light less than 0.5s;

- Adhesive with a color range from transparent to black available, meet any customer’s requirements;

- Low outgassing;

- Halogen-free according to IEC 61249-2-21.

The process of bonding IR filter lenses with DELO adhesive:

Dispense adhesive in the shape of the frame |

Place/align the blue glass to |

Light fixation |

Heat curing at low temperature

|

Needle: G24 | 5 mg / part | LED lamps | Convection oven |

Bondline thickness |

| Irradiation time: | 30 min, 80oC |

Dispensing time: ~ 1.3 s | Wavelength:

|

| |

Aspect ratio: up to |

For more information about DELO adhesive products, please contact us!

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing and curing systems, and technology transfer from DELO in Vietnam.