Application of DELO adhesive specialized for voice coil motor in the camera module

14:29 - 30/09/2020

- VCM parts are made from a variety of materials, but mainly plastic and metal;

- DELO DUALBOND adhesive allows extremely fast fixing of parts with the ability to cure in obscured areas. This is a big advantage because the VCM module has many very small details and has a difficult surface to bond like L

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Today, millions of smartphone cameras are equipped with autofocus (AF) and OIS optical stabilization technology based on the VCM platform. DELO DUALBOND adhesive allows extremely fast fixing of parts with the ability to cure in obscured areas. This is a big advantage because the VCM module has many very small details and has a difficult surface to bond like LCP or PC.

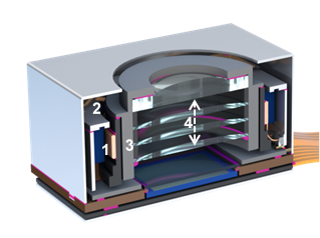

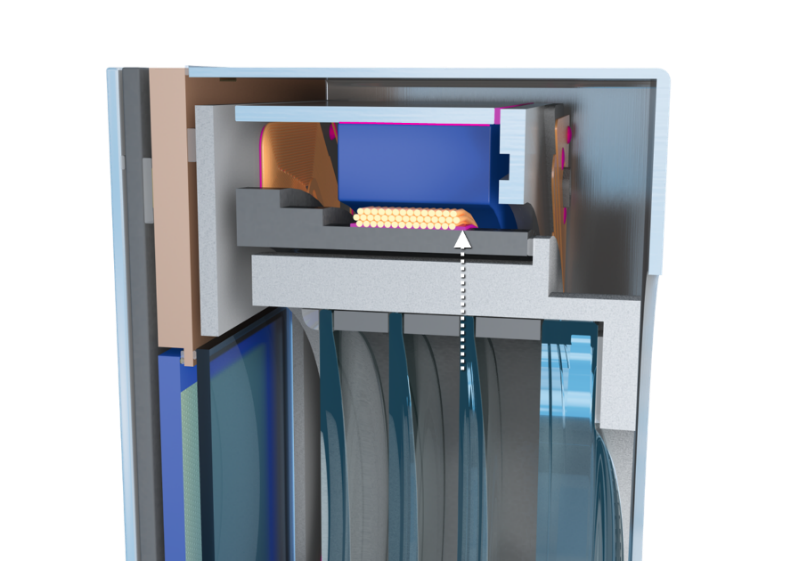

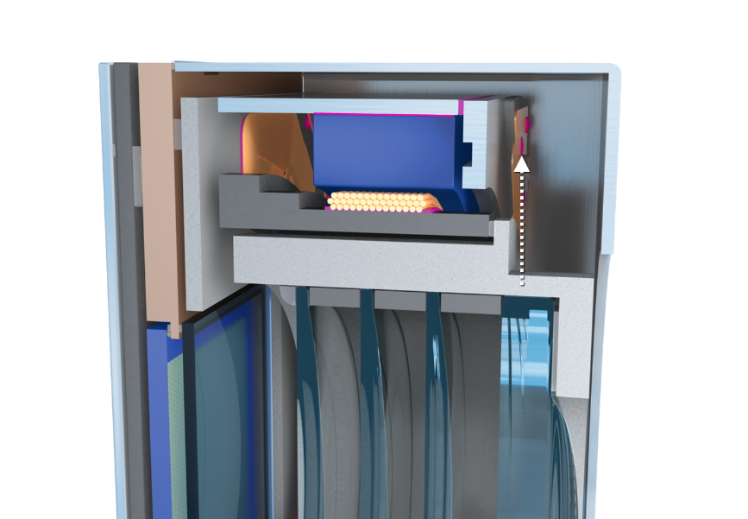

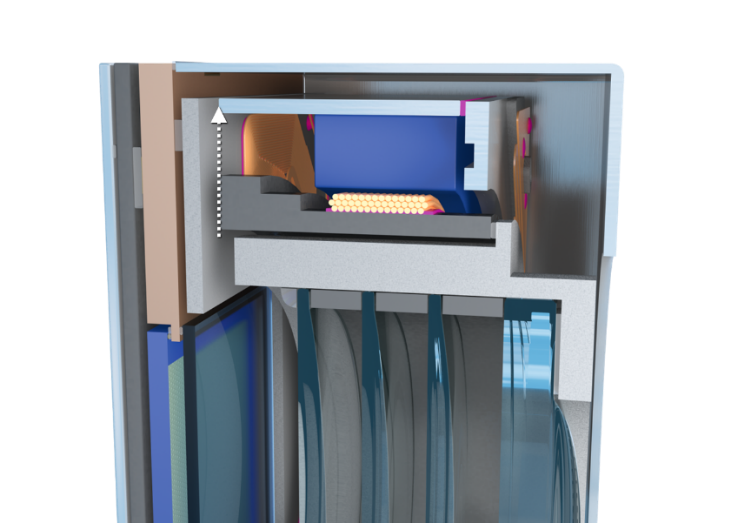

Structure of VCM: includes a permanent magnet (1) integrated into a sliding shell (2) and a portable lens mobile holder containing coil (3). When the voltage is changed, lead to the magnetic field changes, the electromagnetic force generated causes the lens to move parallel to the axis of the sliding shell (4).

VCM parts are made from a variety of materials, but mainly plastic and metal.

Required and tested adhesive properties apply for VCM include:

- UV light fixation in a very short period of time

- No heat curing or even low-temperature curing below +80 °C

- High adhesion to LCP and different metals

- Drop test & tumble test passed

- Very low outgassing, no condensation on the lens due to low outgassing

- Cleaning of the components with water after bonding

- High temperature stability: more than 500 h +85 °C/85 % r.h.

Product lines used for this case:

- DELO DUALBOND AD (light and heat curing)

- DELO DUALBOND AD49… (light and humidity curing)

- DELO DUALBOND và DELO MONOPOX LT (light and heat curing)

- DELO – ML DB (DELO-ML DB180 is suitable) (light and anaerobic curing)

Adhesive and process advantages from which the user can benefit and meet all of the above requirements:

- UV / visible light fixation of components within seconds;

- Low-temperature curing from +60oC;

- DELO DUALBOND LT, or <+80oC;

- UV/light with optional second humidity curing mechanism in shadowed areas;

- Very low outgassing cause no damage to the lens, filter, or sensors;

- Excellent bond strength on substrates used such as LCP and PC and on metals;

- High performance due to fast curing;

- Resistance to drop and tumble test

- Solvent-free components;

- Halogen-free according to IEC 61249-2-21;

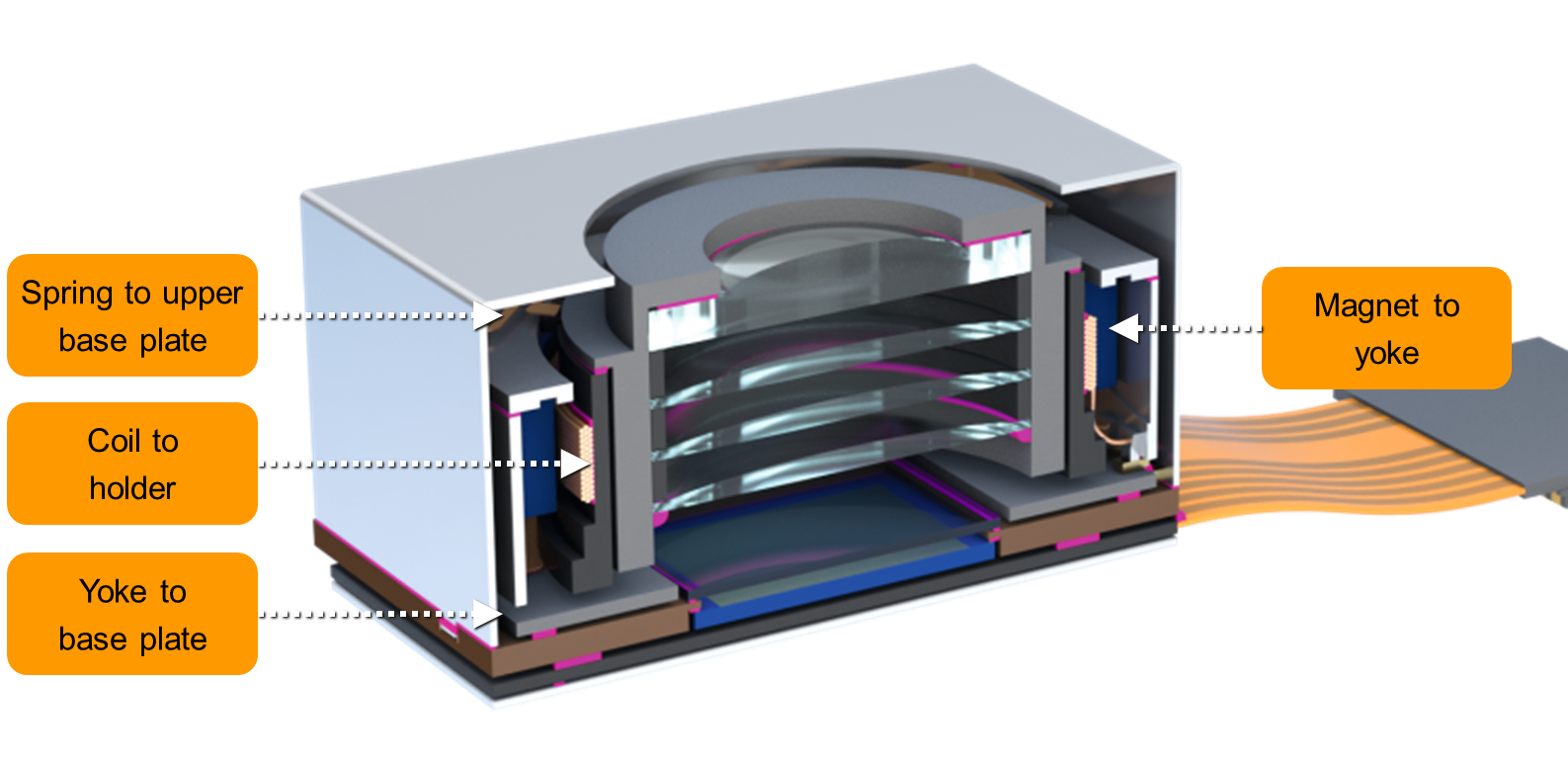

Process of bond components in VCM by DELO adhesive:

Technical parameters for each process:

- Bond magnet to yoke:

|  |  |  |

Placement of magnet on steel yoke | Dispensing | Light fixation | Anaerobic curing

|

| 5 mg per component | LED lamps |

|

| Irrradiation time: | ||

200 mW/cm2 |

| ||

- Bond coil to the lens holder

|  |  |  |  |

Placement of copper coil on | Dispensing: 5 mg per component | Injection of nitrogen to ensure the dry surface | UV Light fixation | Humidity curing |

| Time-pressure dispensing adjustment |

| LED Lamps |

|

| Needle: G27 |

| Wavelength: 365 nm |

|

| Irradiation time: |

| ||

Intensity: 250 mW/cm2 |

| |||

Up to down irradiation |

| |||

- Spring to the upper base plate

|  |  |  |  |

Placement of

| Volume: 10 mg per component | Injection of nitrogen to ensure the dry surface | Light fixation | Humidity curing (>65%) |

| ||||

- Yoke to the base plate

|  |  |  |  |

Placement of nickel Yoke on LCP base plate

| Volume: | Injection of nitrogen to ensure the dry surface | Light fixation | Heat curing or Humidity curing |

| 5 mg per component | Injection time: 2 s | Irradiation time: |

|

| Intensity: 200 mW/cm2 | |||

For more information about DELO adhesive products, please contact us!

HUST Vietnam is proud to being the exclusive distributor of adhesive products, dispensing and curing systems, and technology transfer from DELO in Vietnam.