Introduce:

- DELO-ML DB133 is a modified acrylate adhesive that cures under anaerobic conditions, especially compatible with metal surfaces, quickly fixed by UV light;

- Cured products are generally used in the temperature range of -40 °C to +150 °C; depending on the application, other limits may be more reasonable;

- Complies with RoHS directive 2015/863/EU;

- Compliant with VOC content limit according to GB33372-2020 regulation.

Application:

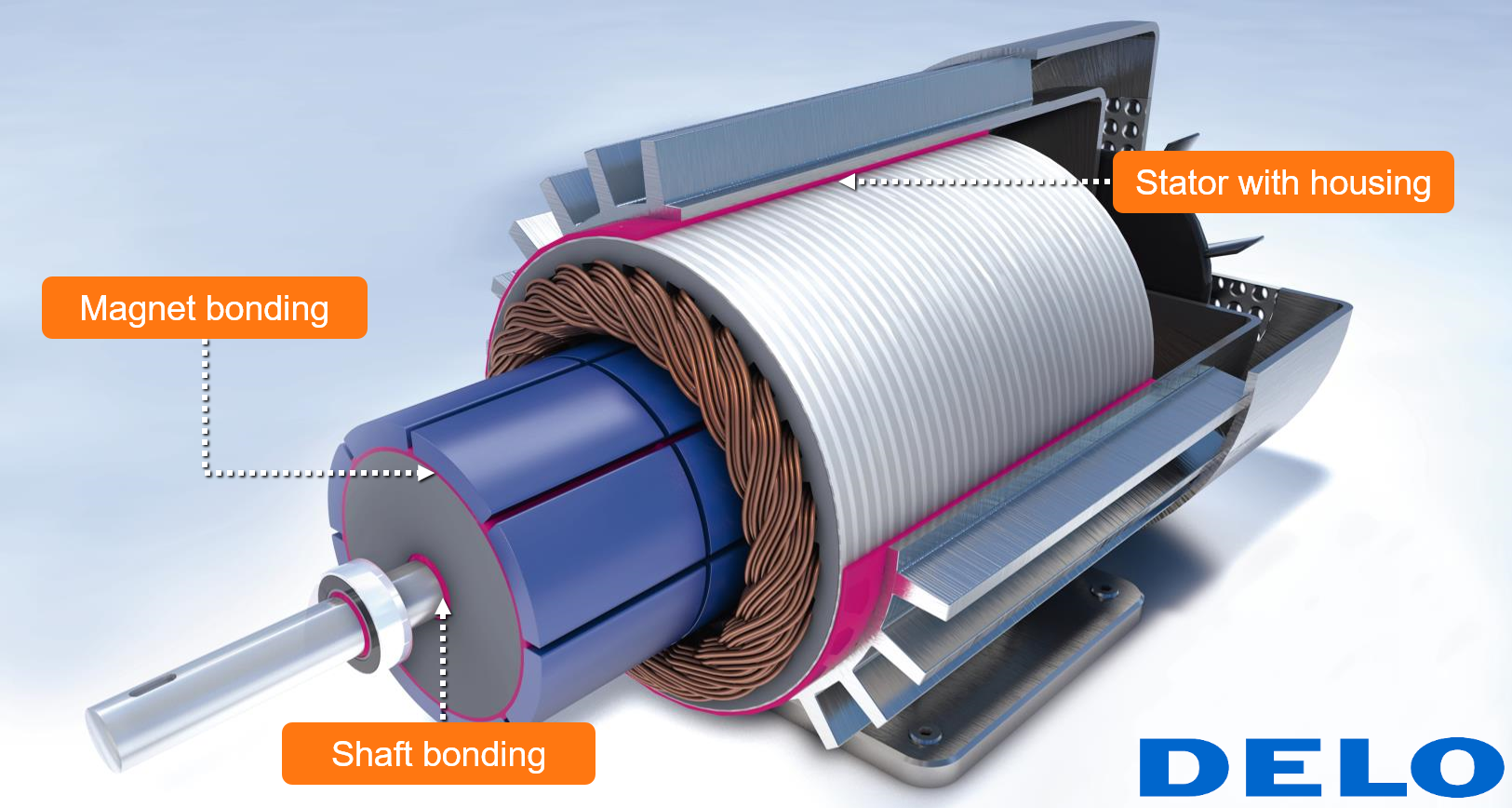

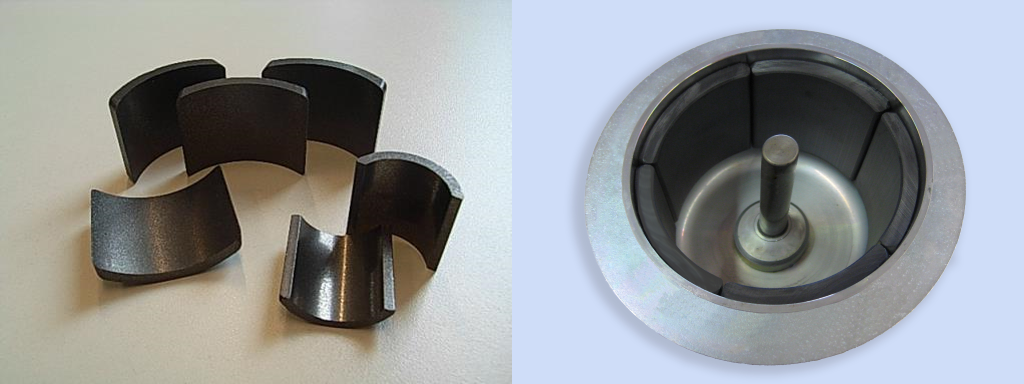

- Applied in adhesive electronic components, Bluetooth headset, electric motor magnet (e-motor) (ferromagnetic type), ...

- The adhesive surface needs to be dry, clean of grease, dirt, acetone, and butyl diglycol acetate can be used to clean the surface. Do not use ethanol or water to clean the surface.

- The glue should be placed in a dedicated DELO adhesive kit.

Application of DELO-ML DB133 glue in electric motor magnets (Photo DELO)

Curing:

- The glue will cure quickly when it comes in contact with the metal surface, the exposed part can be cured by 365nm UV light, the shadowed part can be accelerated curing in the convection oven at 60~80 oC, or let dry naturally.

- ML DB133 glue can also dry naturally under anaerobic conditions and in contact with metal ions on the surface, the glue will initially cure after 3~5 minutes and completely cure after 24 hours.

- The optimal adhesive layer thickness is ≤ 0.25mm, so only a thin layer is required on the surface to be bonded to achieve maximum adhesion.

- Refer to the standard wavelength range of DELOLUX 20/50/80 lamps:

Lamp Type | DELOLUX | ||

Wavelength Range (nm) | 365 | 400 | 460 |

Suitability | ++ | - | - |

Irradiation time (55-60 mW/cm 2 ) | 25s | ||

Note: ++ particularly suitable, + suitable, - not suitable

Specifications:

Color (1.0 mm thick glue): | Transparent, colorless | |

Density: | 1.1 g/cm3 | |

Viscosity (at 23 o C, Rheometer measurement, shear rate: 10 s -1, gap 200µm): | 730 mPas | |

Glue surface after curing: | Hard dry | |

Off-torque: | 30 Nm | |

Tensile shear strength: | Al/Al | 5 MPa |

Al/Al (sand-blasted) | 12 MPa | |

Steel/steel | 11 MPa | |

Steel/steel (sand-blasted) | 14 MPa | |

Compression shear strength: | Glass/glass | 30 MPa |

PA6/Stainless steel | 10 MPa | |

PA5 / PA6 | 18 MPa | |

PMMA / PMMA | 10 MPa | |

PPA/Stainless steel | 16 MPa | |

Tensile strength: | 20 MPa | |

Elongation at tear: | 130 % | |

Young's modulus: | 300 MPa | |

Hardness shore D: | 44 | |

Glass transition temperature: | 1040C | |

CTE coefficient of thermal expansion (in the range of 100~150 0C): | 184 ppm/K | |

Shrinkage: | 8.6 %vol. | |

Volumetric resistance: | > 1x1016 Ohm.cm | |

Surface resistance: | >1x1014 Ohm | |

Processing time after opening the glue bottle cap (at 25 o C): | 72h | |

Storage time (From customer received goods): | 9 months, stored at | |

Contact HUST VN for advice and support in choosing the most suitable solution and glue for the application you are interested in...

HUST Vietnam exclusively distributes adhesive products, dispensing machines, UV glue curing lamps, and technology transfer from DELO in Vietnam.