DELO ADHESIVE APPLIED IN E-MOTOR

14:12 - 09/12/2020

Vehicles using eco-friendly electric motors such as electric motorbike, electric bicycles, or electric cars are increasingly popular and have the big potential to develop in the near future.

Today, in the manufacture of modern electric motors, the most attention is how to increasing motor efficiency. Some solutions are used to include: minimizing the gap between the magnet and t

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Introduction:

Vehicles using eco-friendly electric motors such as electric motorbike, electric bicycles, or electric cars are increasingly popular and have the big potential to develop in the near future.

Today, in the manufacture of modern electric motors, the most attention is how to increasing motor efficiency. Some solutions are used to include: minimizing the gap between the magnet and the winding, replacing the mechanical clamping of parts that be limited mechanical tolerances to the motor housing by adhesive, ...

The use of adhesives has a significant effect not only in design but also help reduce production time, while also improving strength as well as engine quality.

The DELO adhesive products for electric motor applications are possible for all the strictest requirements of manufacturers such as heat resistance, chemical resistance, impact resistance, high tensile strength, ...

HUST Vietnam would like to send readers specific information about DELO's adhesive lines, helping you can be easy to choose the most suitable adhesive for your applications.

DELO product lines | Typical Properties |

DELO – ML DB | Fast fixation by the light within 10 seconds |

DELO DUALBOND | |

DELO-DUOPOX CR | High reliable casting |

DELO MONOPOX GE | |

DELO-DUOPOX | Filling in gaps created by mechanical tolerances |

DELO PUR | |

DELO MONOPOX HT | For high-temperature working applications |

CR=Casting Resin DB=Dual Bonding GE=General Encapsulant HT=High Temperature

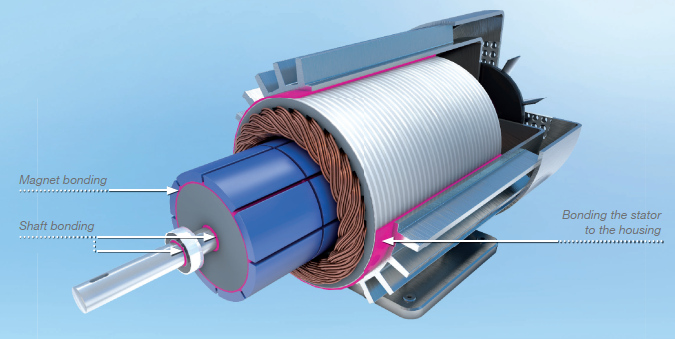

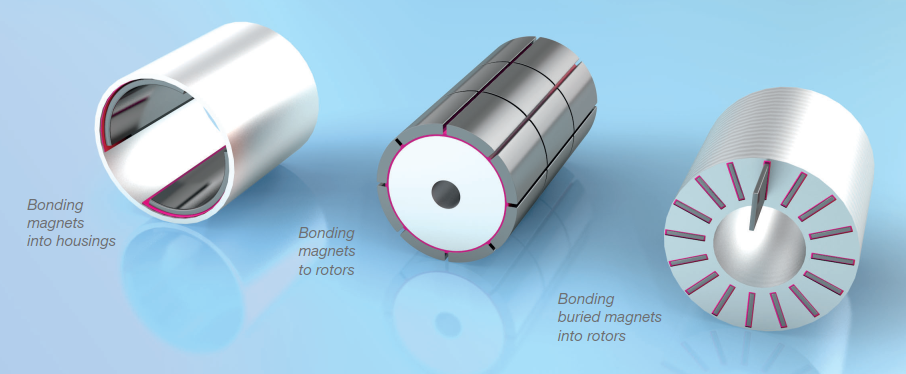

1. Magnet bonding

A rotor is the moving part of an electric motor. Bond magnets to the rotor in electric motors with adhesive offer many outstanding advantages over mechanical connections:

- To minimize mechanical tolerances when assembling parts;

- Evenly distribute the stress;

- Easy to automate;

- Reduce vibration noise;

- Good corrosion protection;

- No component damage during joining;

In addition, some other outstanding features of DELO glue such as:

- High-temperature stability up to +220oC;

- Excellent media resistance;

- Good gap filling;

- Fast light fixation (<10s);

- Tension-equalizing;

For different temperature curing requirements and some other properties of the customer. HUST VN introduces a number of specific adhesive lines.

DELO-ML DB140 DB180 | - Dualbond cured by light and anaerobic; - Fixed by the light within 10s with DELOLUX20 and DELOLUX80 lamps; | Room temperature curing |

DELO-ML 5327 | - Anaerobic curing; - High-temperature stability up to +200oC; - Fast fixed by UV light activator; | |

DELO DUOPOX SJ8665 DELO-PUR 9694 | - 2 components adhesive derived from polyurethane; - Peeling strength; | |

DELO DUALBOND SJ2718 | - 1 component adhesive; - Fast fixed by light; - Dualbond by light/heat methods; | High-temperature curing |

DELO MONOPOX HT2860 | - 1 component adhesive; - Impact strength; - High-temperature stability up to +200oC; - Fast curing by heat; | |

DELO MONOPOX SJ2981 | - 1 component adhesive derived from epoxy resin; - Run-resistant; |

ML=Metal Light DB=Dual Bonding HT=High Temperature SJ=Structural Joining

2. Bond stator to housing

The stator part in an electric motor is a fixable part, consisting of coils assembled together and with the motor housing. Typically, assembling these parts together is usually by compression or mechanical thermal expansion. Today, the technology of using glue in modern electric motors offers many outstanding advantages that can completely replace the above mechanical method.

Typically properties of DELO adhesive as:

- Equalize tensions between the stator and housing with different CTEs of stator and housing. Therefore, motor durability improve when continue working, makes high temperature due to friction force;

- Heat to assembly parts is not mandatory like the mechanical thermal expansion method;

- More cost-efficient production;

- Improved acoustics by damping properties of the adhesive;

- Larger production tolerance possible than mechanical assembly;

Some other outstanding features of DELO adhesive in this application:

- High-temperature stability up to +200oC;

- Fast light fixation short cycle times (DELO-ML DB);

- Accelerated curing with an activator (DELO-ML);

- Curing at room temperature (except for DELO MONOPOX);

Some adhesive product lines suitable for this application are summary by HUST Vietnam and showed on the table as below:

DELO-ML DB140 DB180 | - Dualbond cured by light and anaerobically condition; - Fixation by the light within 10s with DELOLUX20 and DELOLUX80 lamps - Good impact strength; | Room temperature curing |

ML 5327 | - Anaerobic curing; - High-temperature stability up to +200oC; - Fast fixed by UV light activator; | |

DUOPOX | - 2 components adhesive derived from polyurethane; - High peeling strength; - Good impact strength; - Gap filling > 250 μm. | |

DUALBOND SJ2718 | - 1 component adhesive; - Fast fixed by light - Dualbond by light and heat methods; - Gap filling > 250 μm. | High-temperature curing |

DB = Dual Bonding ML = Metal Light SJ = Structural Joining

3. Shaft bonding

In electric motors, the motor shaft is bonded with the shaft bearing, rotor package, and commutator. Low viscosity and curing properties in anaerobic environments are preferred for the adhesion of small openings and with low tolerances. Using DELO adhesive offers many advantages such as:

- Low component production costs;

- Easy to automate;

- No clearance, no-slip;

- No friction or contact corrosion;

Some other advantage of DELO adhesive:

- Fast fixation by light or activator (DELO-ML);

- Curing at room temperature (DELO-ML, DELO DUOPOX);

- High-temperature stability up to +220oC;

For detail of some suitable adhesive with this application, refer to summary information in the following table:

DELO-ML DB140 | - Dualbond cured by light and anaerobically condition; - Fast fixation by the light within 10s with DELOLUX20 and DELOLUX80 lamps; - Good impact strength; | Room temperature curing |

DELO-ML 5327 | - Anaerobic curing; - High-temperature stability up to +200oC; - Fast fixed by UV light activator; | |

DELO-DUOPOX SJ8665 | - 2 components adhesive derived from polyurethane; - Peeling strength; - Good impact strength; - Gap filling > 250 μm. | |

DELO DUALBOND SJ2718 | - 1 component adhesive; - Fast fixed by light; - Dualbond by light and heat methods; - Gap filling > 250 μm. | High-temperature curing |

DELO MONOPOX HT2860 | - 1 component adhesive derived from modified epoxy resin; - High-temperature stability up to +220oC; - Fast fixed by UV light activator; - Curing by heat method; - Gap filling > 250 μm. |

DB = Dual Bonding HT = High Temperature ML = Metal Light SJ=Structural Joining

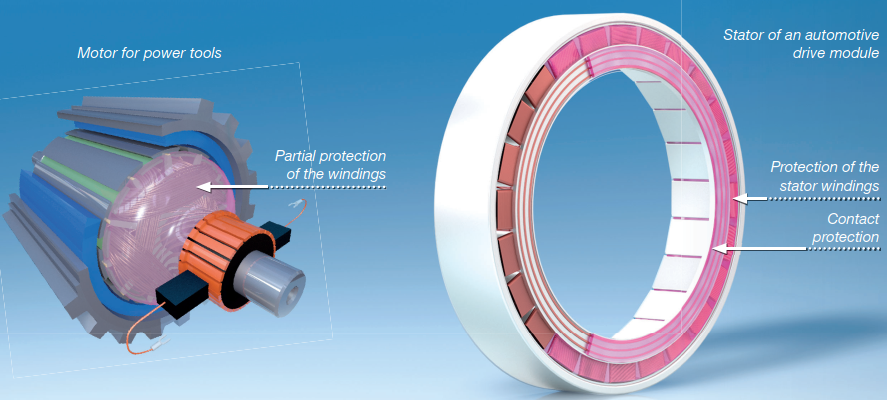

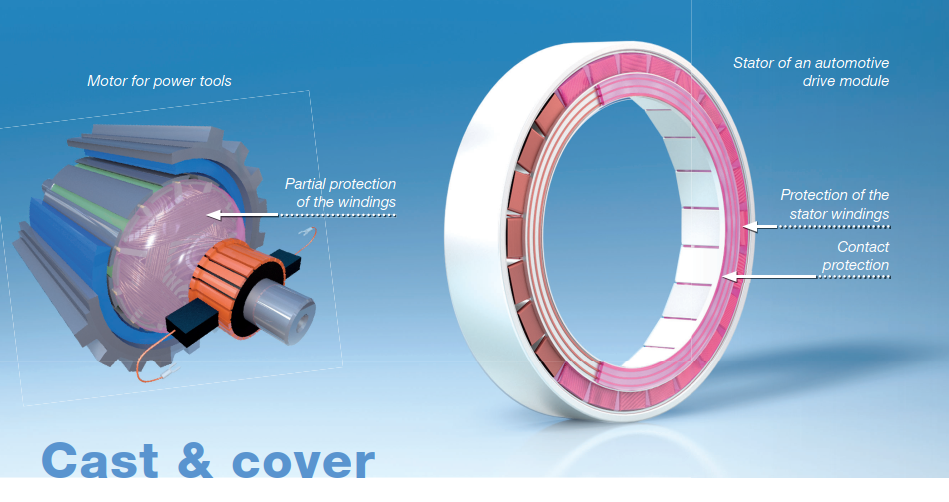

4. Cast and cover

Components should be cover with adhesive in electric motors to protect the sensors from the effects of moisture, solvents, or mechanical impact forces. Therefore, the DELO adhesive used in this application has specific uses such as:

- Secure coil wires against vibration;

- Cover soldered and welded contacts to protect them against corrosion;

- Partial protection of windings from abrasive substances;

- Stator casting;

Some characteristic properties of DELO adhesive bring outstanding advantage to e-motor:

- Excellent resistance to aggressive substances (e.g. gear oil);

- Outstanding thermal resistance and low thermal expansion combine to minimize tensions between cast and component;

- Very fast fixation or curing by light;

Below are characteristic properties that recommend use for cast and cover applications related to e-motor:

DELO DUOPOX CR8031 | - 2 component adhesive; - High reliable; - Accelerate curing speed by heat addition; | Room temperature curing |

DELO KATIOBOND 45952 | - Fast fixation by light activator; - Curing by the light within the 60s with DELOLUX 80 lamp; | |

DELO DUALBOND AD4950 | - Dualbond by light and humidity; - Curing irradiation time within 10s with DELOLUX 80; - High flexible adhesive; | |

DELO MONOPOX GE727 | - 1 component adhesive; - High strength and high reliability; - Low Coefficient of Thermal Expand (CTE =11 ppm/K); | High-temperature curing |

DELO MONOPOX GE785 | - Run-resistance; - Low Coefficient of Thermal Expand (CTE =22 ppm/K); | |

DELO DUALPOX CR8715 | - 2 component casting resin; - Low CTE (29 ppm/K); - High reliability; | |

DELO DUALBOND AD761 | - Dual curing by light and heat; - Irradiation time within 30 s with DELOLUX 80; | |

DELO DUALBOND AD465 | - Dual curing by light and heat; - Irradiation time within 4s with DELOLUX 80; - High reliability; |

AD = Adhesive GE = General Encapsulant CR = Cast Resin

Above special properties of DELO adhesive products that be recommended for e-motor application and also be used in some other sector in industrial manufactures.

For more information, please contact us.

HUST is proud to be the exclusive distributor of adhesive products, dispensing, adhesive curing systems, and technology transfer from DELO in Vietnam!