Introduce:

DELO-DUOPOX TC8686 (TC=Thermal Conductive) is a 2-component adhesive, base on modified epoxy resin, that cures at room temperature for 168h but will accelerate to cure within 1h when heated to +80 oC. It is developed for the application of Lithium battery pack bonding application to heat sinks for batteries in electric vehicles.

- Compliant RoHS certified according to directive 2015/863/EU;

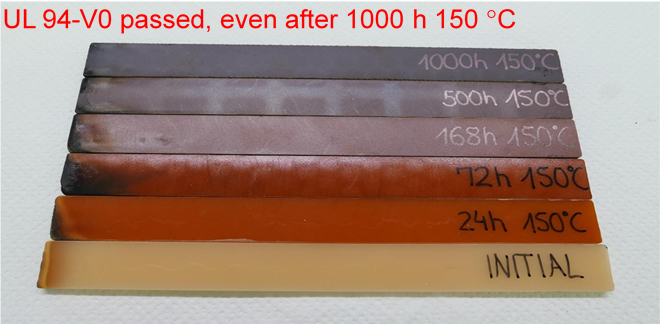

- Passed ANSI/UL 94 V-0 Flammability Test.

Featured applications:

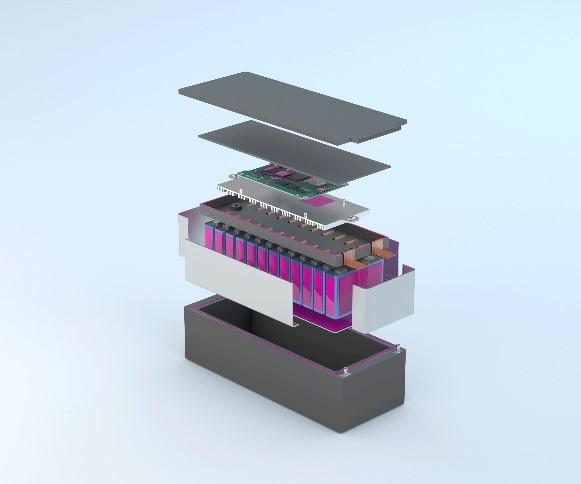

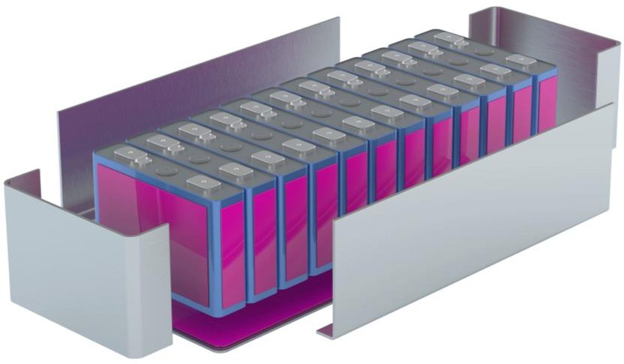

Today's electric vehicles (electric cars, electric motorcycles, ...) mainly use lithium-ion polymer battery technology to provide power for the engine. When the car is operating, these batteries will gradually heat up, if the heat sink is not good, it can lead to damage to the battery or even cause an explosion.

Mechanically, when connecting battery cells in a battery, there will be openings for the heat sink. However, air conducts thermal quite low (0.024 W/mK), moreover requires very precise assembly so that the battery is not affected by external environmental factors. Meanwhile, DELO-DUOPOX TC8686 glue has many times higher thermal conductivity (1.0 W/mK), making the battery extremely efficient at sinking heat.

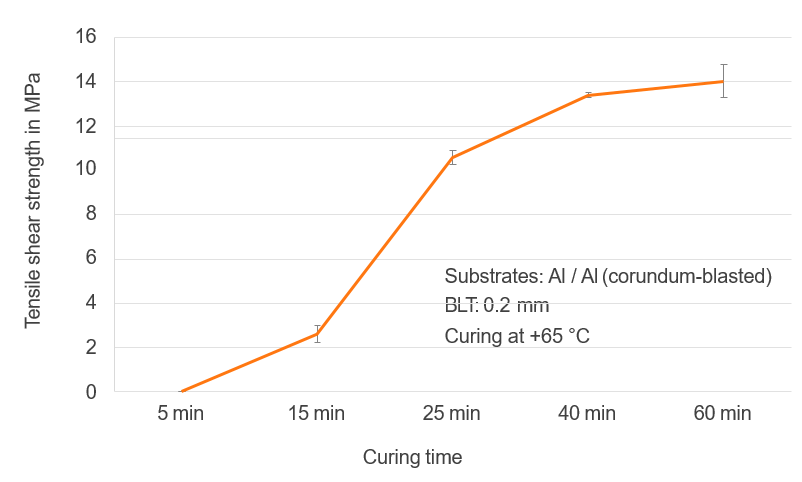

Curing:

Curing temperature condition | 23 o C | 80 o C |

- Initial curing time (traction force 1~2 MPa) | 3.5 h | 15 minutes |

- Functional curing time (until reaching tensile force > 10MPa) | 8 h | 25 minutes |

- Final curing time | 7 days | 60 minutes |

Specifications:

- Mixing ratio A: B by volume: | 2: 1 | |

- Color when the curing layer thickness is 1 mm: | Beige (whitish) | |

- Processing time after mixing at 23 o C with 100g glue: | 60 minutes | |

- Processing time after mixing at 35 o C with 100g glue: | 40 minutes | |

- Viscosity (Liquid, Rheometer, Shear rate: 2 (1/s), Gap 500 µm): | A | 50000 mPas |

B | 240000 mPas | |

- Tensile shear strength (MPa) on Al/Al bond (sandblasted treatment, cured at 23oC for 168h): | 16 MPa | |

- Tensile strength: | 23 MPa | |

- Elongation at tear: | 2 % | |

- Young's modulus: | 3700 MPa | |

- Shore D hardness: | 80 | |

- Specific Thermal conductivity (DELO Standard 47): | 1.0 W/m.K | |

- Dielectric strength (According to DIN EN 60243-1 standard): | 22 kV/mm | |

Creep resistance CTI M (According to DIN IEC 60112): | 600 M | |

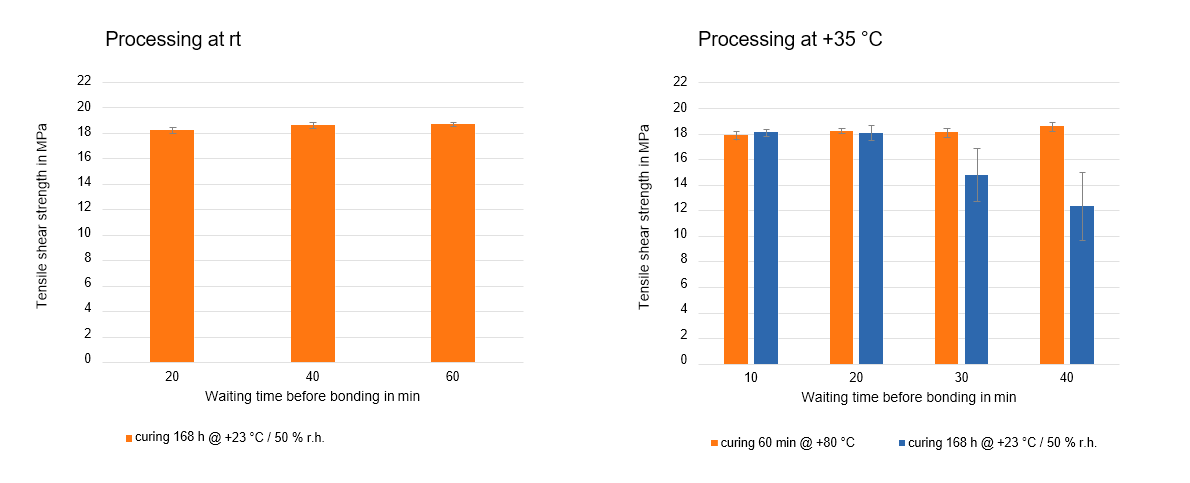

- For the production and assembly of the battery cells, the application of glue and the drying of the glue can take a long time, so the TC8686 glue is adjusted so that the glue lifetime is equivalent to the glue drying time to make the production more efficient. smoothly, continuously.

- The glue has been tested to measure the sliding tensile strength for different time periods to investigate the optimal lifetime to apply the glue.

- At an ambient temperature of 23 o C, the glue after mixing can maintain the state before gelation for 60 minutes, and with the temperature increased to 35 o C, the glue can still live for 40 minutes, enough time. for glue in production.

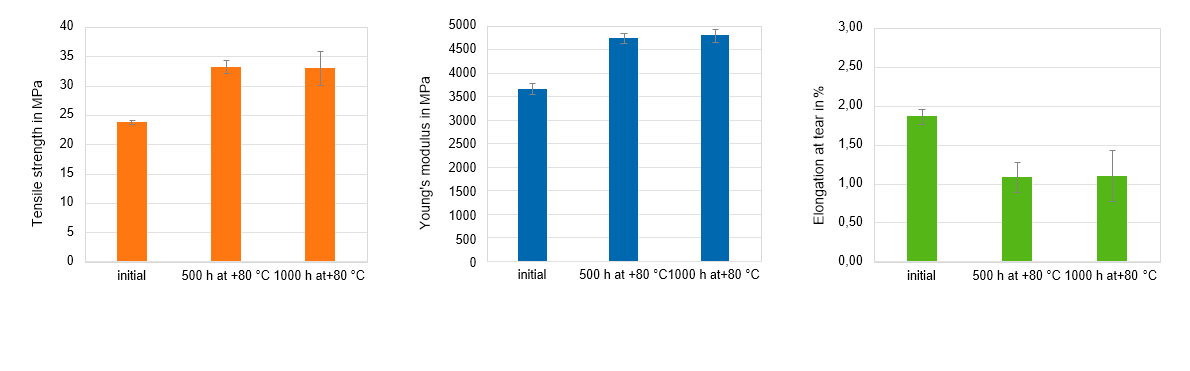

Evaluation of mechanical - physical-chemical properties of glue:

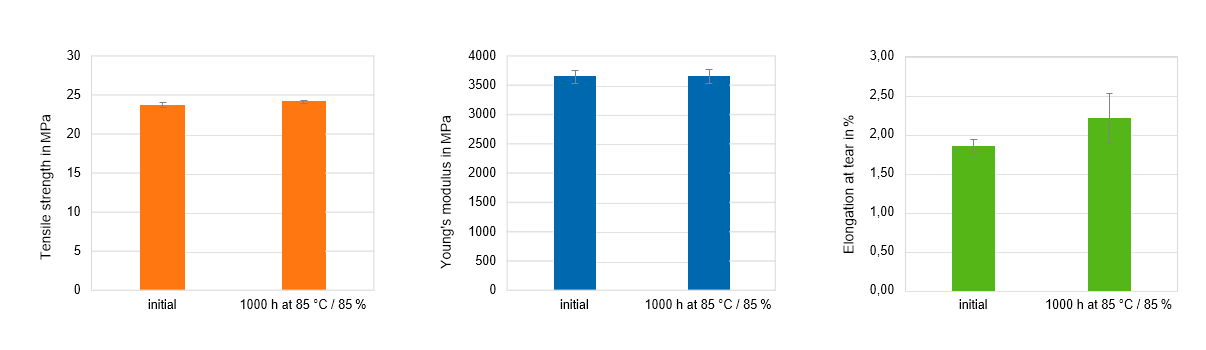

- TC8686 has exceptional mechanical properties, tensile strength, and Young's modulus increase when tested stored at +80 °C for 1000h.

- When the storage conditions are 85 oC and 85% RH, the glue also gives constant tensile strength:

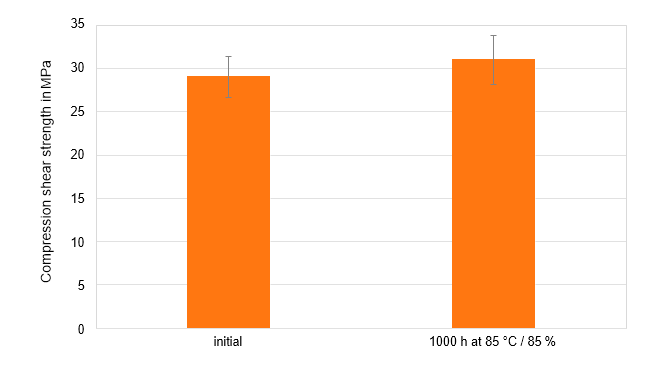

- Even compression shear strength is also higher:

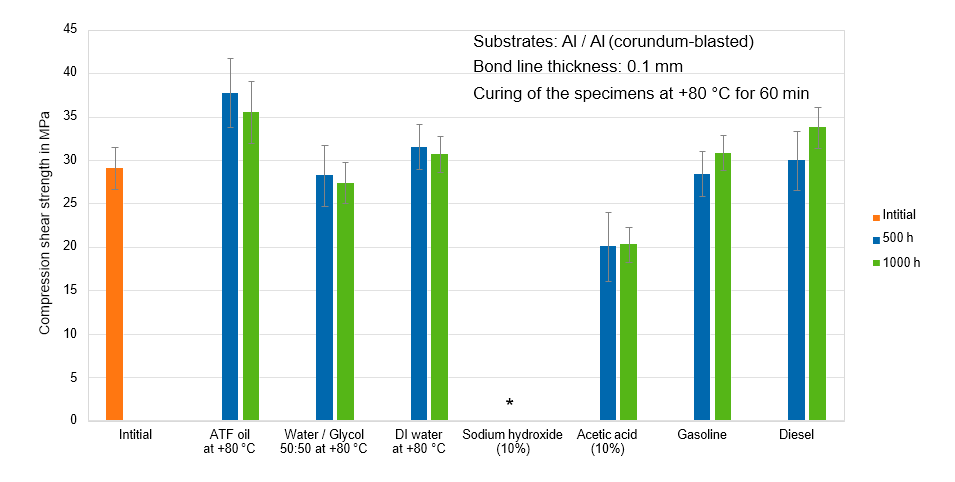

- Tested with corrosive solvents, TC8686 glue also exhibits excellent corrosion resistance:

- The actual test of fire resistance:

Packaging:

- Glue is contained in dual tubes of AUTOMIX which is convenient for mixing glue to ensure the ratio of 2 components A: B = 2:1 with volumes of 50ml, 200ml.

- In addition, there are 750ml single-component bottles, or 20l, 200l, etc.

Contact us for more information.

HUST Vietnam is proud to be the exclusive distributor of DELO's adhesive products and dispensing and curing systems, technology transfer in Vietnam!