DELO-DUOPOX AD8xx – ADHESIVE GROUP CREATES HIGH MECHANICAL STRUCTURES

Introduce:

DELO-DUOPOX AD8xx adhesive group (AD = Adhesives) is a 2-component adhesive line, originating from modified epoxy resin, curing at room temperature or accelerating when heated to +80 o C, and is a resistant adhesive line. high temperature up to +150 o C and packaged in a double glue bottle, easy to apply glue both manually and automatically.

Outstanding features:

- The glue is padded with inorganic mineral particles to strengthen the material's mechanical properties.

- The adhesive has a high viscosity, prevents creep when applying glue, suitable for large gaps that need to be bonded.

- Usage temperature range: from -40 °C to +150 °C depending on the type of glue and specific application.

- The adhesive is durable at high temperatures, has good solvent resistance, and is durable in the peeling test.

- The time to apply glue after mixing is from 30 to 90 minutes, enough for manual manipulation without the glue gelling.

- All glue labels meet RoHS standards according to directive 2015/863/EU.

Featured applications:

▪ Adhesive is suitable for structural adhesive applications, has large sizes, suitable for many materials such as steel, aluminum, glass, carbon composite, plastic,...

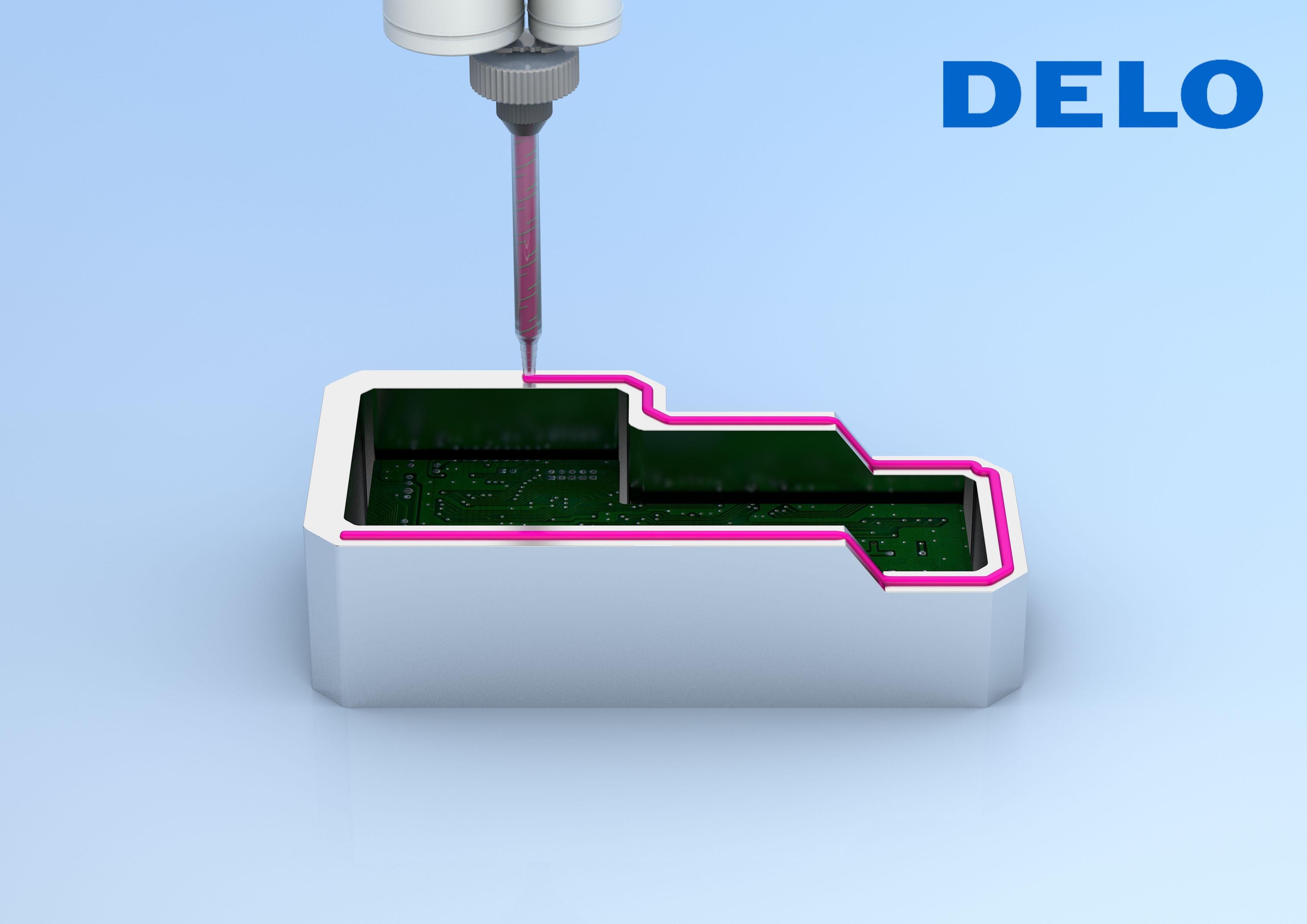

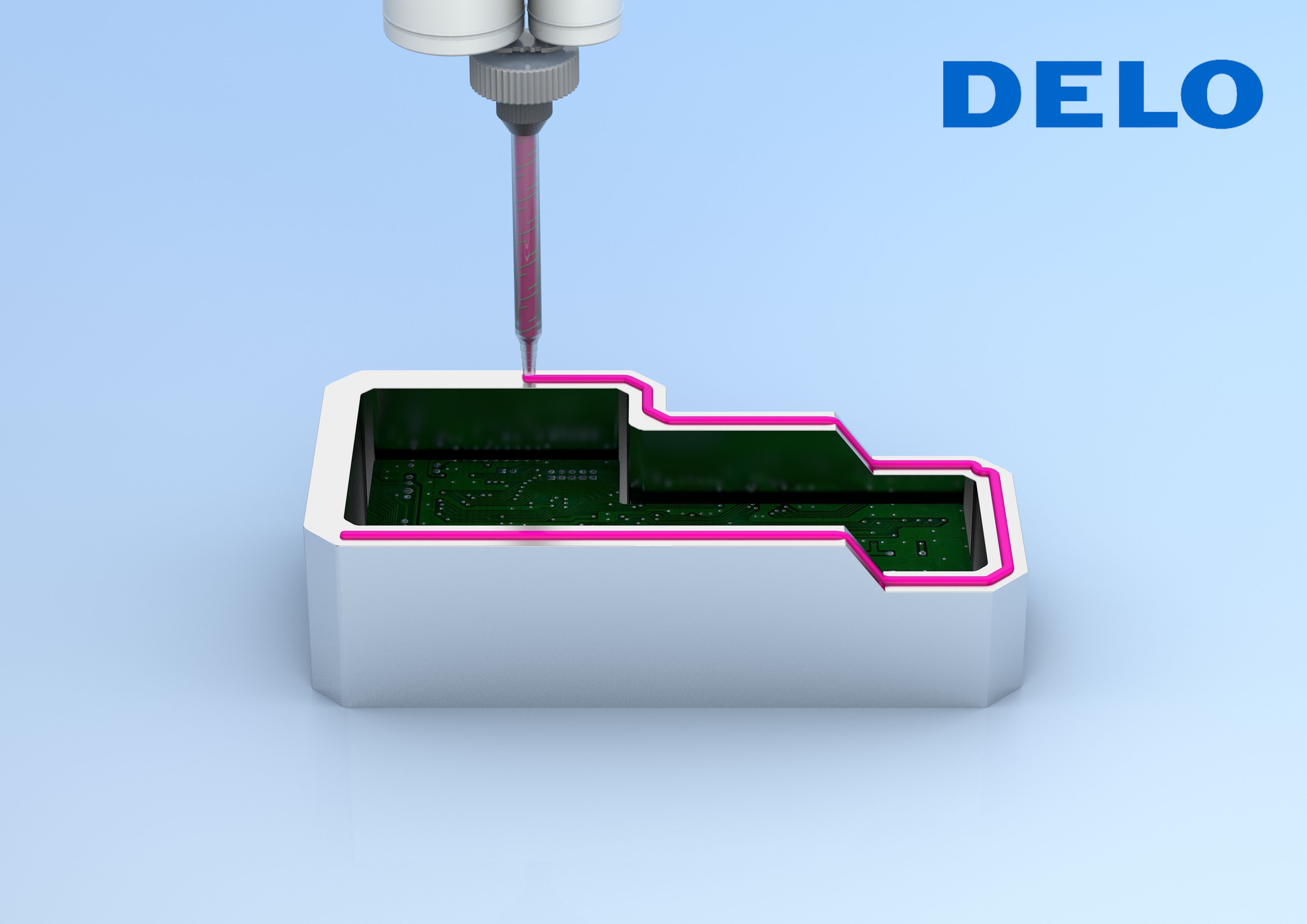

1. Adhesive electronic components box

- Adhesive / seal the outer shell of the component.

Material composition

- Metal, Al

- Plastic, PA

Choose adhesive

- DELO-DUOPOX AD840

2 . Adhesive the frame connection parts of wheelchairs and racing bicycles

Material composition:

- CFRP (carbon fiber reinforced plastics)

Choose adhesive:

- WORK-DUOPOX AD895

3. Sensor packaging:

- Fix and protect the sensor's PCB circuit to the box.

- Requires resistance to oil penetration and high temperatures up to 160 oC).

- Insulation for electronic components and cables.

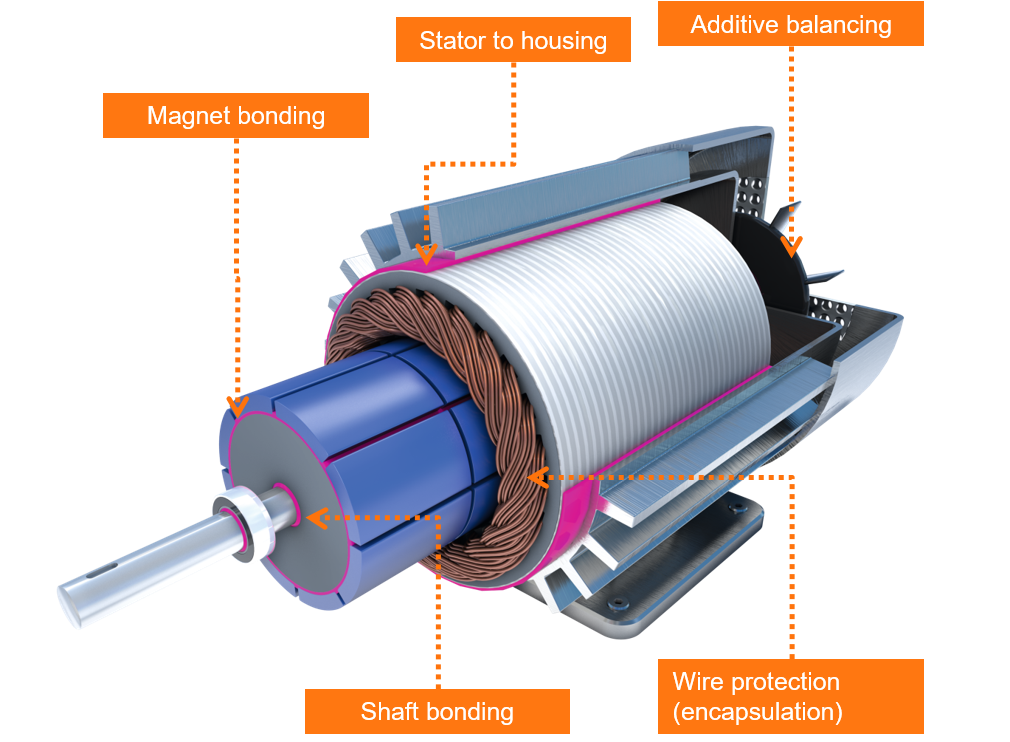

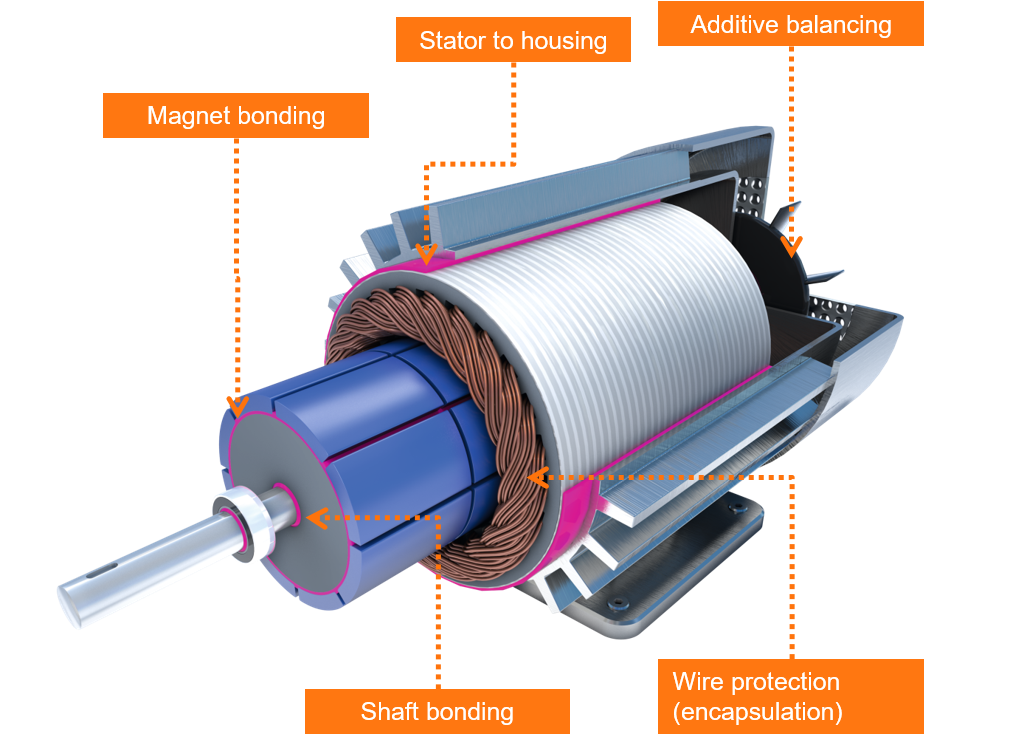

4. Bonding the magnet and the shaft of the electric motor

- The glue flow is customizable and provides high mechanical strength.

- Adhere the stator to the motor body.

- The glue has good tensile strength balance.

- Protect electrical wires.

- Glue can be fixed quickly.

- Dynamically balance the motor, ensuring it is not eccentric when rotating.

- The glue application process is simple and quick.

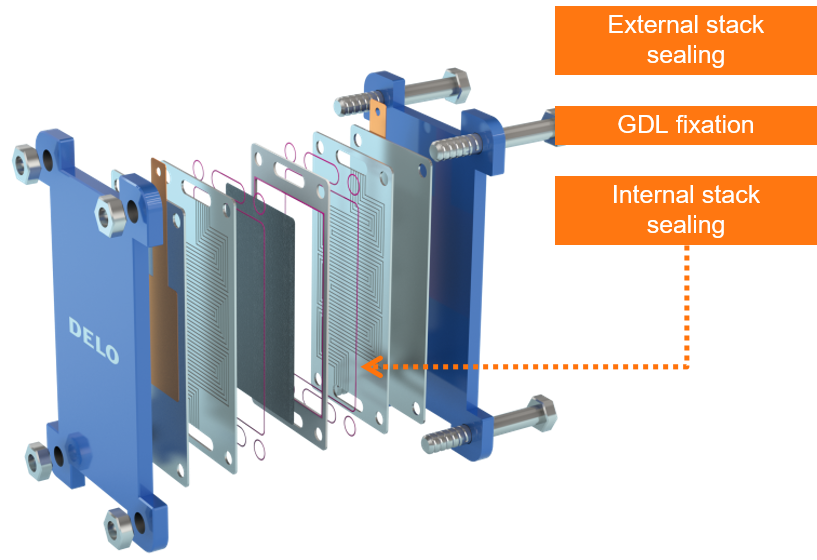

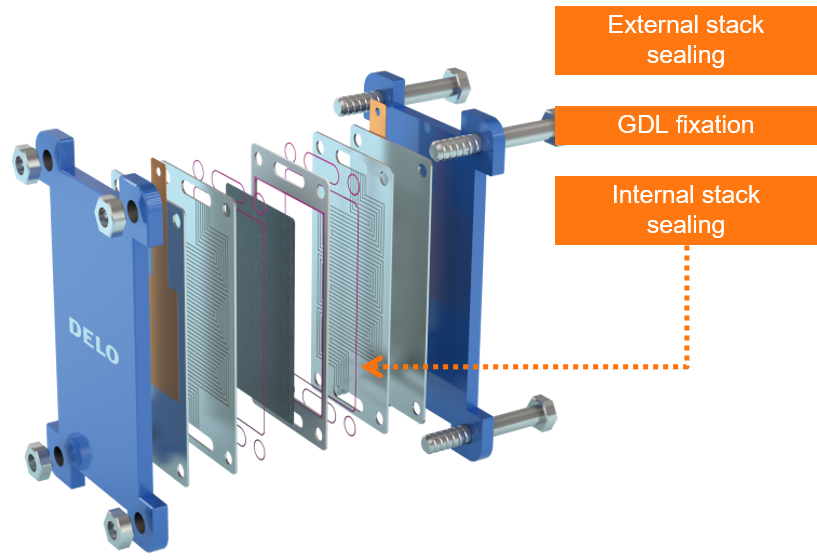

5. Adhesive and seal the plates in the fuel cell

- Bonding of the gas dispersion layer to the catalytic coating layer.

- Adhere the floating frames to the outside.

- Seal and bond the bipolar panels to the housing frame.

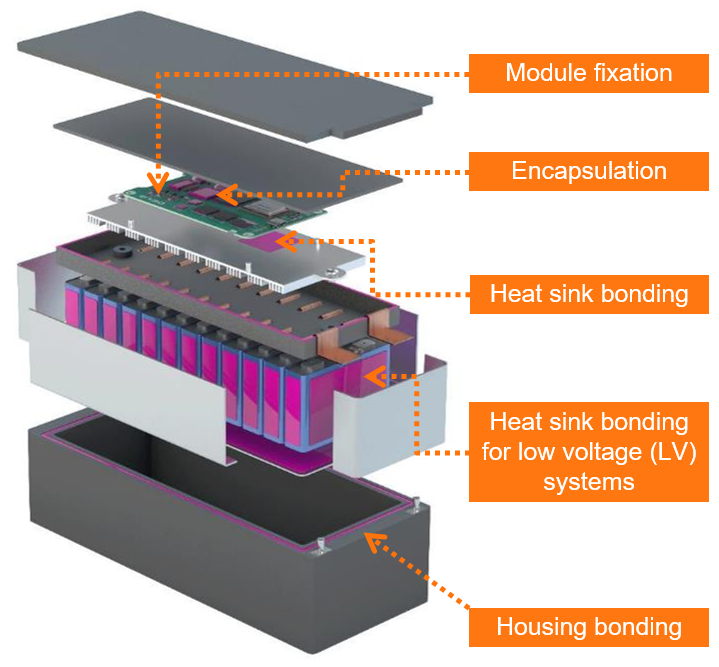

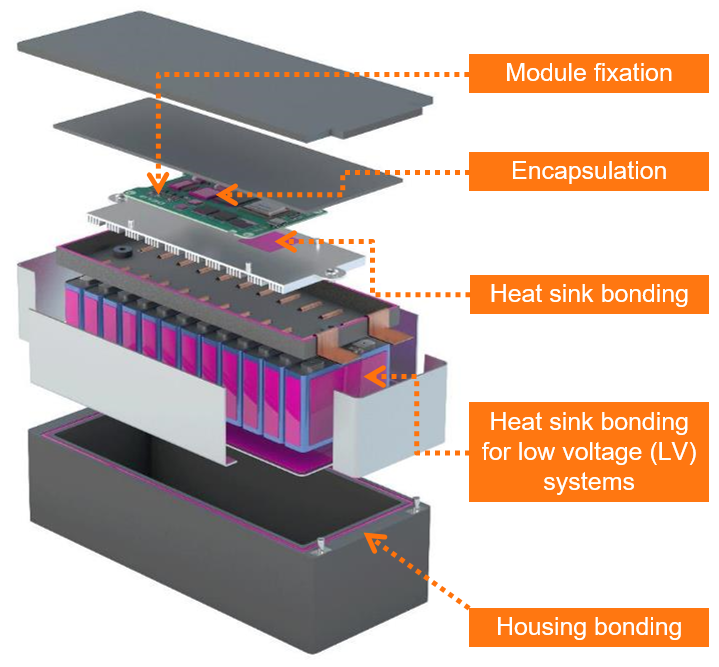

6. Adhesion in lithium batteries

- Adhesive shell frame.

- Adhesive and seal different parts of the battery pack body.

- Thermal conductive adhesive.

- Adhesives create structure for battery cells, or to transfer heat with thermally conductive adhesive lines.

- Encapsulation of the control circuit.

- Protects, fixes, or strengthens electronic components on PCB circuits.

- Fixed module.

Specifications:

Parameter | |||||||

Ingredient | 2-component glue, from modified epoxy | ||||||

Color | Gray, opaque | Black, opaque | Gray, opaque | ||||

Filler beads | Inorganic minerals | ||||||

Application | structural adhesion | ||||||

Usage temperature | -40 ~ + 150 oC | -40 ~ + 140 oC | |||||

Glue application time | 90 min | 90 min | 45 min | 30 min | 30 min | ||

Storage period | 12 months | 6 months | 6 months | 12 months | 12 months | ||

Time to start curing | at 23 oC | 7h | 7h | 5h | 5.5h | 6h | |

at 80 oC | 13 min |

|

|

|

| ||

Complete curing time | at 23 oC | 7 days | 7 days | 24 hours | 24 hours | 24 hours | |

at 80 oC | 1h |

|

|

|

| ||

Mixing ratio (vol.) | 1:1 | 2:1 | |||||

Density (g/cm 3 ) | A (monomer) | 1.18 | 1.19 | 1.37 | 1.37 | 1.37 | |

B (hardener) | 1.33 | 1.37 | 1.18 | 1.19 | 1.17 | ||

Viscosity (mPa.s) | A (monomer) | 110000 | 310000 | 40000 | Special | ||

B (hardener) | 125000 | 530000 | 30000 | ||||

Shear tensile strength (Tensile shear strength) (Theo DIN EN 1465, (MPa) | Al/Al (sand grinding, glue dries at 23oC for 7 days) | 22 | 21 | 19 | 19 | 17 | |

4 (measured at 120 oC) |

|

|

| 2.8 (measured at 100 oC) | |||

Steel/steel, (glue dries at 23oC for 7 days) | 22 (sand grinding) | 19 |

|

|

| ||

Peel-off tensile strength (Steel/steel, glue dries at 23oC for 7 days) | 6 N/m | 7 N/m (Sand grinding) | 0.7 N/m (Sand grinding) | 1.2 N/mm | 1.3 N/mm | ||

Tensile (Tensile strength) (Theo DIN ISO 527) (MPa) | 8 | 30 | 41 | 40 | 42 | ||

Compression shear strength (MPa) | ABS/ABS (adhesive dries at 23 oC, within 7 days) | 7.5 |

|

|

|

| |

Al/Al (glue dries at 23 oC, within 7 days) | 26 |

|

|

|

| ||

Al/Al (sand grinding, glue drying at 80oC for 30 min) | 34 |

|

|

|

| ||

Steel/steel (adhesive dries at 23 oC for 7 days) | 30 |

|

|

|

| ||

Glass / Glass (Adhesive dries at 23 oC for 7 days) | 29 |

|

|

|

| ||

PA6/PA6 | 17 | 18 (Thermal annealing pretreatment) |

|

|

| ||

PC-ABS/PC-ABS | 13 |

|

|

|

| ||

FR4/FR4 |

| 32 |

|

|

| ||

Elongation at break | 6% | 4% | 2.1% | 2 % | 1.8 % | ||

Young's stress (MPa) | 1700 | 1800 | 2300 | 2400 | 2500 | ||

Shore hardness | D 76 | D 75 | D 73 | D 73 | D 77 | ||

Glass transition heat (oC) | 69 | 70 | 63 | 66 (TMA) 102 (DMTA) | 64 | ||

Thermal expansion coefficient | 160 ppm/K (30~150 oC) |

| 178 ppm/K (70~150 oC) | 178 ppm/K (70~150 oC) | 177 ppm/K (70~160 oC) | ||

Shrinkage (%vol) | 3 %vol. | 2%vol. | 4%vol. | 4 %vol. | 4 %vol. | ||

Water absorption | 0.18 %wt. |

| 0.3 %wt. | 0.25 %wt. | 0.25 %wt. | ||

Destructive temperature | 280 oC | 283 oC | 215 oC | 200 oC | 200 oC | ||

Dielectric strength (According to DIN EN 60243-1 standard) | 25 kV/mm |

| 14 kV/mm | 13.7 kV/mm | 14 kV/mm | ||

Special properties | - Meets ISO 10993-5 standard: - Meets VOC content requirements according to GB33372-2020. | - Meets ISO 10993-5 standard: | - Meets VOC content requirements according to GB33372-2020. - Durable at high temperatures and resistant to solvents. | - Meets ISO 10993-5 standard: - Meets VOC content requirements according to GB33372-2020, durable at high temperatures, and resistant to solvents | - Durable at high temperatures and resistant to solvents | ||

Contact us for more detailed information.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing technology, curing, and technology transfer from DELO in Vietnam!