DELO-DUOPOX CR80xx – POTTING, CASTING ADHESIVE GROUP

Introduce:

DELO-DUOPOX CR80xx adhesive group (CR = Casting Resin) is a 2-component adhesive, originating from modified epoxy resin, curing at room temperature or accelerating when heated to +80 o C, and is a resistant adhesive line. high temperature up to +180 o C and packaged in a double glue bottle, easy to apply glue both manually and automatically.

Outstanding features:

» Glue without mineral particles, suitable for requirements to reduce density on glued parts, non-conductive, does not affect the operation of components.

» The adhesive has low viscosity and maintains flow when pumping, ensuring full filling of small details and complex shapes.

» Usable temperature range from -40 oC to + 140 oC.

» Good heat resistance (180 oC - CR8031).

» Good chemical resistance (CR8021).

» The time to apply glue after mixing is from 45 to 85 minutes, enough for manual manipulation without the glue gelling.

Featured application:

▪ Adhesives are used for many different purposes such as molding copper coils in electric motors, covering PCB circuit boards, molding sensors, ...

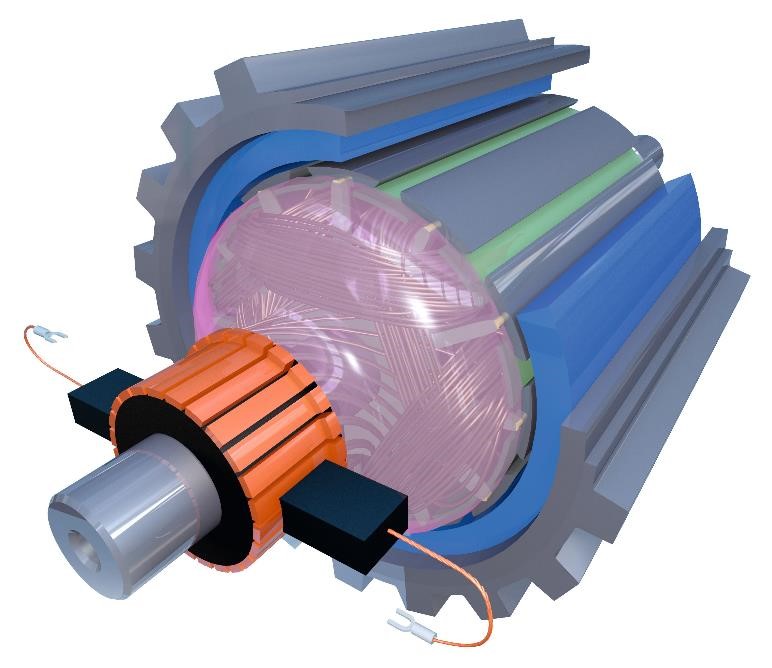

1. Application: E-motor

- Fix the coil.

- Covers the weld contact.

Material Composition:

- Copper wire is covered with an insulating layer.

- Solder wire.

- PA plastic.

Selected adhesive:

- DELO-DUOPOX CR8031

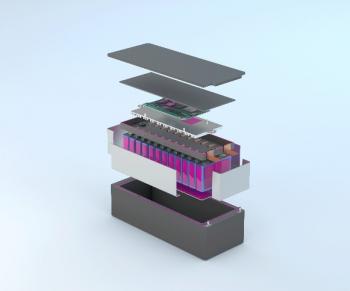

2. Application in Smart card

- Adhere to the PET plastic chip layers of the plastic card.

- The adhesive fills the space between the integrated components (screen, battery...) and the outer plastic coating.

Material composition:

- PET plastic foil layer

Selected adhesive:

- DELO-DUOPOX CR8021

Basic requirements of adhesive:

- The adhesive does not affect the card when bent.

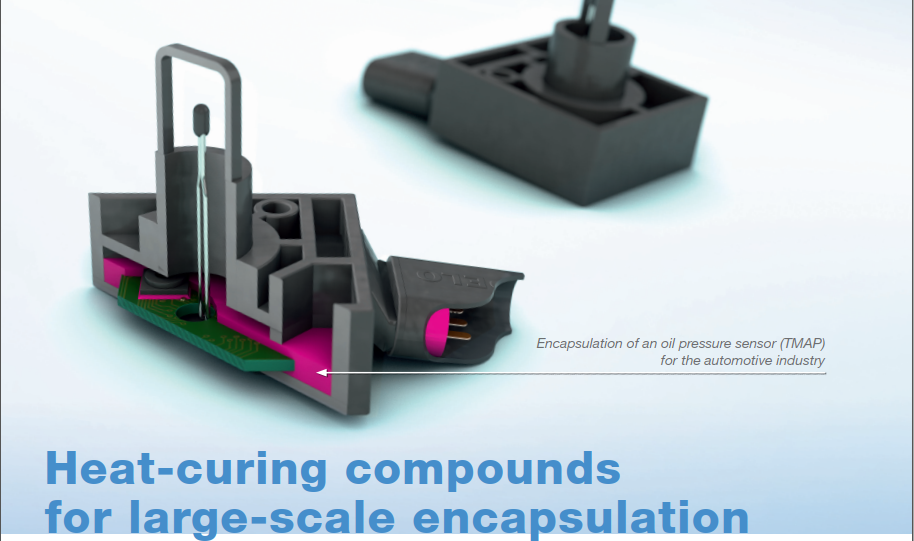

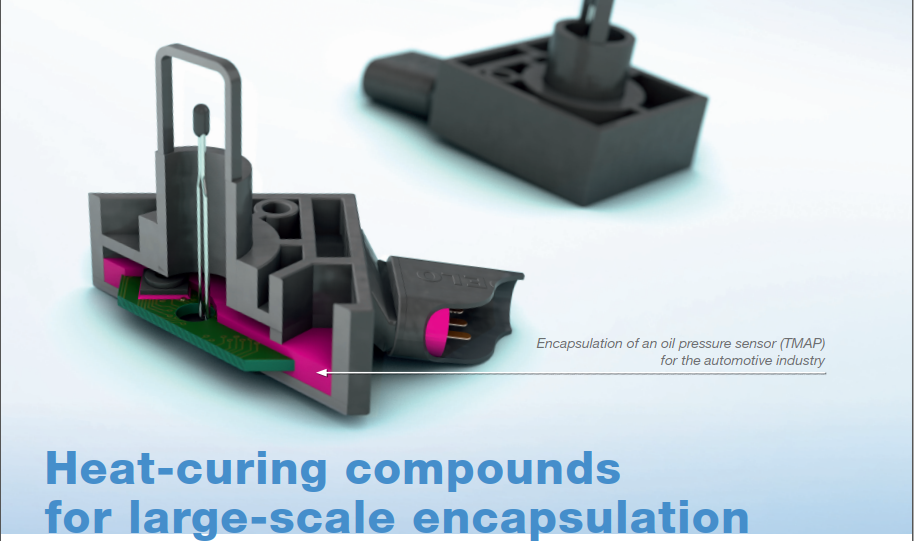

3. Application of Potting microswitches, and ultrasonic sensors in cars:

Selected adhesive: DELO-DUOPOX CR8021

- Maintain good flow.

- Low shrinkage.

- Corrosion resistance and good elasticity.

- Low water absorption.

- Anti-creep and high dielectric strength.

- Multi-purpose applications in mechanical, electrical, and electronic engineering.

- Easy handling with dual cartridges, optimized for precise mixing ratios and automation.

Specifications:

Parameters | ||||||

Ingredient | 2-component glue, from modified epoxy | |||||

Color | Pale yellow, opaque | Light yellow, transparent | Pale yellow, opaque | Black, opaque | ||

Application | Molding and bonding | Casting, potting | Casting, potting | Casting, potting | ||

Usage temperature | -40 ~ + 140 oC | -40 ~ + 120 oC | -40 ~ + 140 oC | -40 ~ + 180 oC | ||

Mixing ratio | 0.72:1 (vol.) | 1.68:1 (vol.) | 0.5 : 1 (vol.) | 2:1 (vol.) | ||

Density (g/cm 3 ) | A (monomer) | 1.17 | 1.19 | 1.18 | 1.15 | |

B (hardener) | 0.98 | 1.04 | 1.03 | 0.97 | ||

Viscosity (mPa.s) | A (monomer) | 10000 | 12000 | 34000 | 18000 | |

B (hardener) | 330 | 6000 | 10000 | 11000 | ||

Glue application time | 50 min | 15 min | 60 min | 85 min | ||

Storage time | 9 months | 9 months | 12 months |

| ||

Time to start curing | at 23 oC | 8h | 8h | 5.5h | 8h | |

at 80 oC | 15 min | 15 min | 5 min | 10 min | ||

Complete curing time | at 23 oC | 72h | 72h | 72h | 7 days | |

at 80 oC | 2h | 2h | 1.5h | 1h | ||

Shear tensile strength (Tensile shear strength) (Theo DIN EN 1465, Al/Al) (MPa) | 13 | 10 | 11 | 16 | ||

Compression shear strength (MPa) | 9 (PA66/PA66) |

|

|

| ||

Tensile (Tensile strength) (Theo DIN ISO 527) (MPa) | 8 | 52 | 9 | 40 | ||

Elongation at break | 45% | 2% | 35% |

| ||

Young's stress (MPa) | 77 | 2400 | 100 | 1700 | ||

Shore hardness | D 46 | D 77 | D 47 | D 72 | ||

Glass transition heat (oC) | 50 | 74 | 47 | 66 (TMA) 102 (DMTA) | ||

Thermal expansion coefficient |

|

| 250 ppm/K (30~50 oC) | 112 ppm/K (30~50 oC) | ||

Shrinkage (%vol) | 3.5 %vol. | 3.5%vol. | 3%vol. | 4 %vol. | ||

Water absorption | 0.6 %wt. | 0.1 %wt. | 0.5 %wt. | 0.23 %wt. | ||

Destructive temperature | 208 oC |

| 277 oC | 252 oC | ||

Contact us for more detailed information.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing technology, curing, and technology transfer from DELO in Vietnam!