Choosing the right adhesive for the magnet to housing bonding in E-motor

14:41 - 15/03/2022

Today's magnets are usually fixed to the chassis or motor shaft with glue.

Depending on the type of magnet and the specific application and the requirements of the manufacturers, DELO has its own suitable adhesives.

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Choosing the right adhesive for the magnet to housing bonding in E-motor

The electric motor mentioned here is an asynchronous 1-phase DC motor, operating on the principle of using permanent magnets and copper coils to generate electromagnetic force to help the motor operate.

There are 2 mechanisms for manufacturing DC electric motors:

- Structure 1: The magnet is fixed to the motor body (the stator is stationary), and the motor shaft is attached to copper coils (the rotor rotates), electrically connected by a brush mechanism. This structure is often found in small, low-power electric motors with a simple structure such as in turbocharger pumps, electric fans, etc. This type of motor usually uses ferromagnetic Ferrite magnets with high durability and relatively low cost.

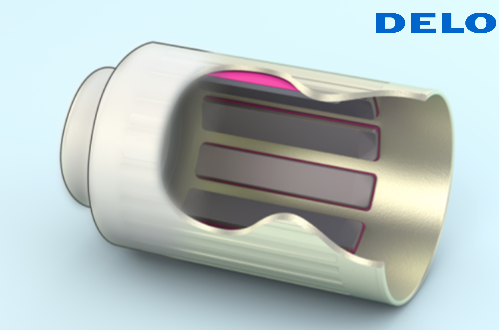

The motor uses ferromagnetic Ferrite magnets (DELO Photo)

- Structure 2: The magnet is fixed to the motor shaft (the rotor is moving), and the motor housing frame will be attached to the copper coils (the stator part is fixed). This is a somewhat superior mechanism compared to mechanism 1 because it does not need a brush mechanism. This type of engine is often found in modern electric vehicles, requiring high durability in harsh environments and for large capacity. To meet that requirement, the type of magnet used for this motor is often used as Neodymium (NdFeB) or Samarium Cobalt (SmCo), these are permanent magnets with high magnetic fields and relatively large production costs.

|  |

| Neodymium (NdFeB) magnets and motors in electric vehicles (EVs) (DELO photo) | |

Today's magnets are usually fixed to the chassis or motor shaft with glue.

Depending on the type of magnet and the specific application and the requirements of the manufacturers, DELO has its own suitable adhesives.

HUST Vietnam has compiled and hopes this article can help readers have an easier choice:

1. What kind of glue do ferromagnetic Ferrite magnets use?

Ferrite magnet: use DELO–ML DB133 or DELO DUOPOX SJ8665 adhesive.

Ferrite - Permanent magnets are usually made from iron oxide sintered with barium or strontium carbonate, easily manufactured by sintering or pressing. They are strong and can be easily demagnetized. This is a magnet commonly used in civil equipment such as speakers, electric fans, water pumps, ..., and low magnetic, so the price is also the cheapest.

- With the main component being iron oxide, so the magnet has a fairly active surface, using the DELO–ML DB133 metal glue line will be especially suitable. Under the catalytic action of metal ions on the surface, the adhesive quickly solidifies and gives maximum bonding force.

- Because DELO-ML DB133 is an anaerobic adhesive, it is necessary to have a high tightness between the contact surfaces, the part of the glue that is exposed to the air can be irradiated with UV light for drying. Hot drying with heat will also help the glue dry faster.

- For passive surfaces such as engine covers, a surfactant such as DELO-QUICK 5004 should be added to both increase the speed of solidification and increase adhesion.

- DELO DUOPOX SJ8665 2-component epoxy adhesive line is also an optimal choice if fast curing speed is not required, the glue can dry and stick firmly within 3-5 hours or only 30 minutes if dried at 80 o C.

|  |

| Bond magnet to housing in e-motor by DUOPOX SJ8665 to give high reliability (HUST Photo) | |

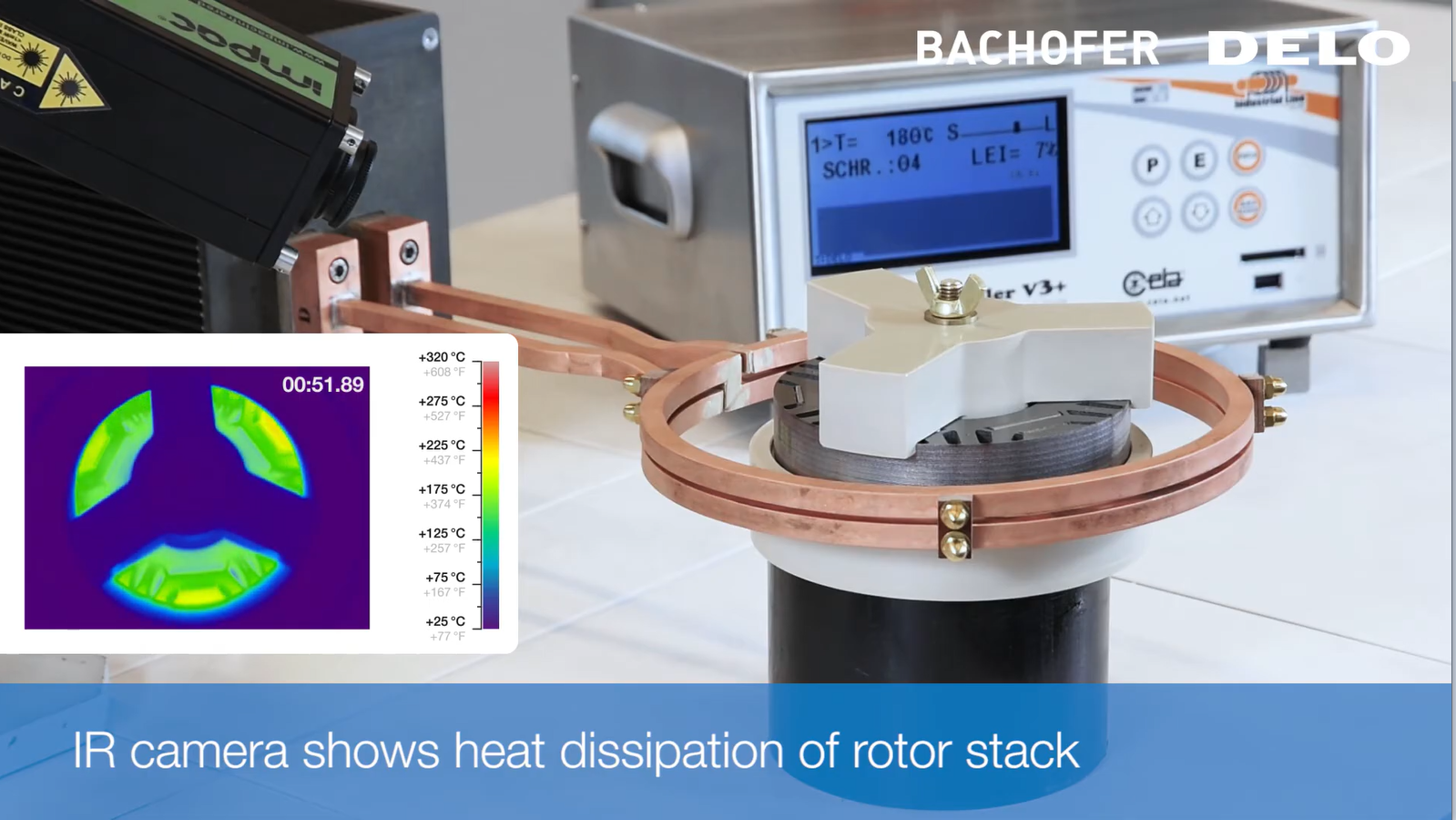

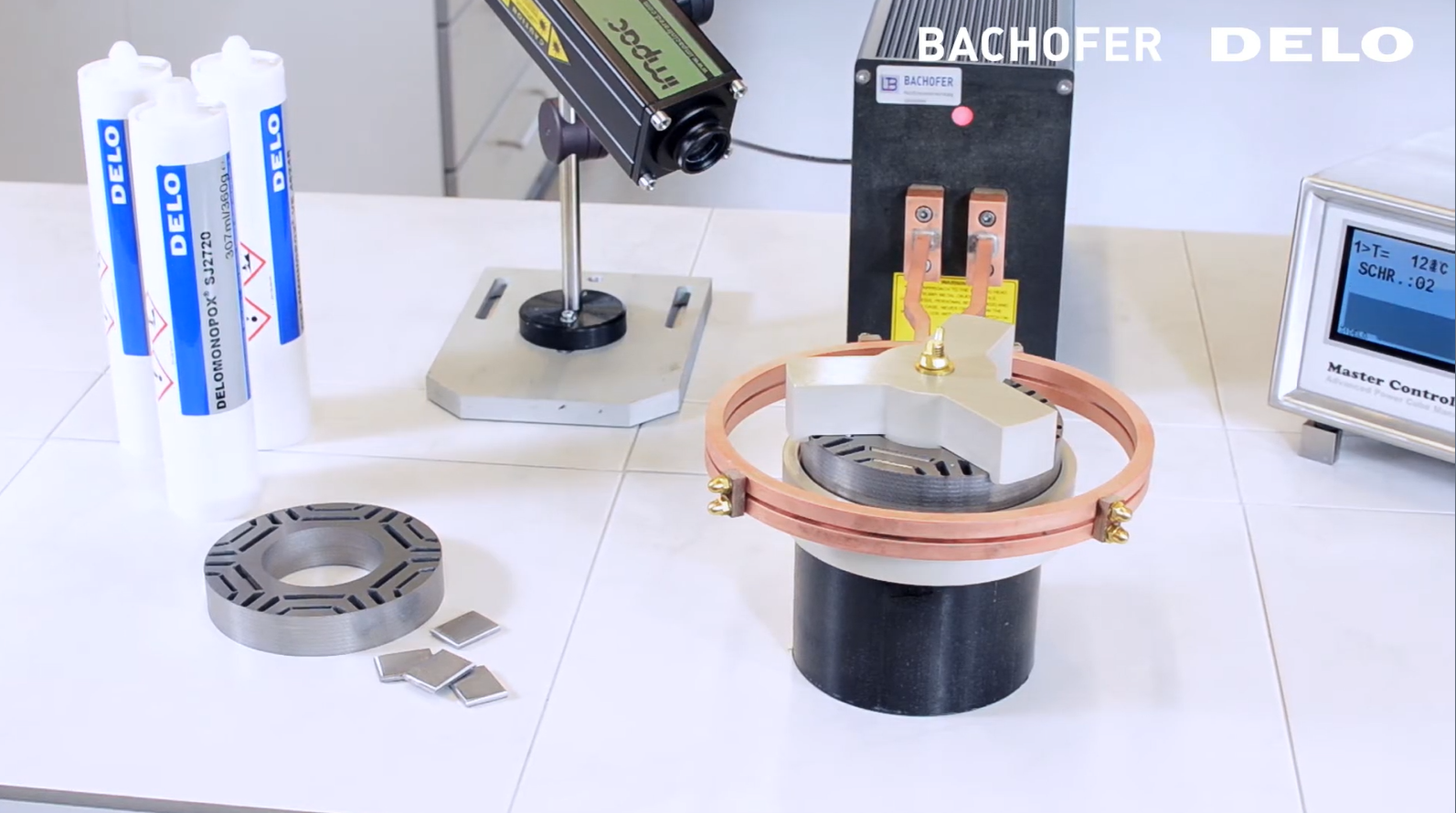

If the glue application can use heat, we have more options such as the DELO MONOPOX glue line, with electromagnetic induction drying technology, it takes less than 1 minute to dry the glue and move on to the next stage according to.

|  |

| Electric motor glue drying technology by electromagnetic induction (Photo DELO) | |

Learn more: Glue curing technology by electromagnetic induction heat

2. What glue is used for Neodymium Iron Boron (NdFeB) magnets?

- Use DELO-ML DB180 glue in combination with DELO-QUICK 5004 activator.

Neodymium Iron Boron (NdFeB) magnets, commonly known as Neodymium, Iron, Boron, or Neo Magnets, are rare earth magnets made of an alloy of Neodymium, iron, and boron. The first magnets were invented in 1982 by General Motors and Sumitomo Special Metals. Neodymium magnets are currently the strongest permanent magnets available today. This is a rare earth magnet, with the strongest magnetic field, so the price is also very high.

EBM Papst's electric motor uses Neodymium magnets and DELO glue (DELO photo)

NdFeB magnets are often used in electric vehicle motors such as cars, electric motorcycles, etc. With strong magnetic properties, high durability, resistance to corrosive solvents, and harsh weather conditions, male NdFeB magnets are the perfect choice to build a powerful motor.

DELO–ML DB180 adhesive with fast drying, transparent, heat resistant range from -60 ~ +180 o C, resistant to solvents, well meets the requirements of engines that often have to operate at high intensity and in extreme weather conditions.

Standard NdFeB magnets after manufacturing are always coated with a protective layer against Ni-Cu-Ni corrosion, creating a passive surface, so it is necessary to use additional surfactants such as DELO-QUICK 5004.

DELO-ML DB180 also belongs to the anaerobic glue line, so the condition for the glue to dry and create adhesion is to not be in contact with oxygen in the air, the adhesive surfaces need to be tight, and activators can be used. , UV light, and/or temperature to accelerate the curing of the adhesive.

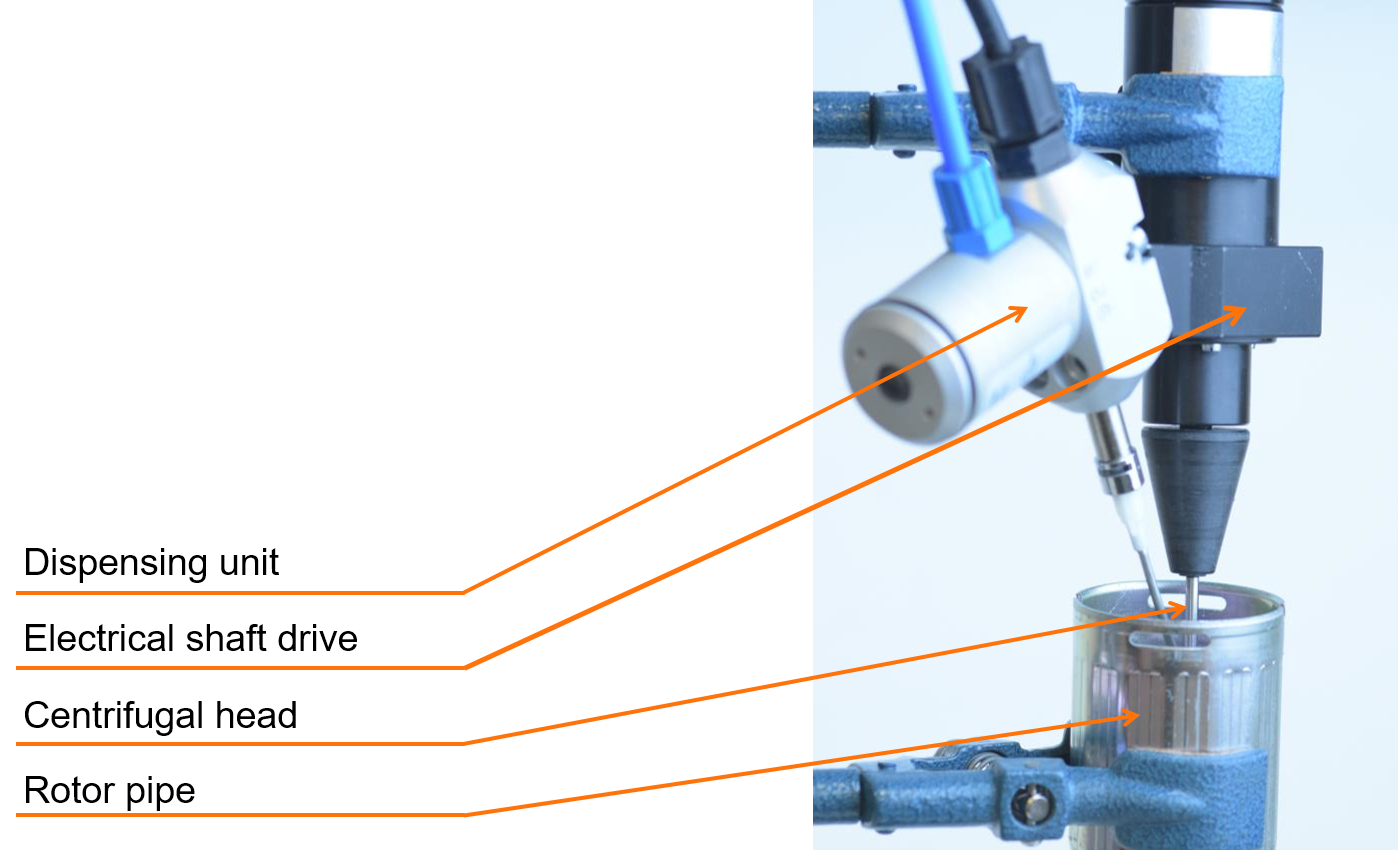

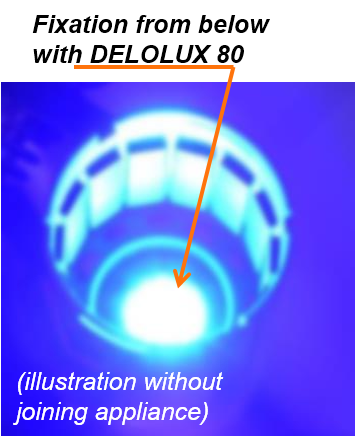

Gluing technique uses a clamping valve (Pinch) and DELO-QUICK 5004 activator spray head in centrifugation. Dry the glue with UV DELOLUX lamp 20 for 10s.

The time glue starts to cure after about 5 minutes and is relatively dry to move on to the next stage is 1 hour, the glue is completely cured after 24 hours.

|  |

| Glue application and glue drying technology for electric motor magnets are fully automatic (Photo DELO) | |

- Other options: DELO DUALBOND SJ2718.

For motor models that can be dried at temperatures as high as 130 o C, DUALBOND SJ2718 glue can be used, which will give extremely high compressive strength (~60 MPa). The adhesive series is compatible with engines that need to operate at high speeds, and in harsh vibration environments.

- DELO MONOPOX series adhesives are also available in a wide range of compatibility for this application, featuring high-temperature curing, the 1-component epoxy adhesive that offers outstanding tensile/compression/bending strength and resistance heat up to 200 ° C.

DELO MONOPOX adhesive fully meets the most demanding requirements for product quality and reliability.

There are also a number of other magnets used in electric motors, but less commonly, such as Samarium Cobalt (SmCo) magnets.

With many years of experience in developing specific adhesives for each production project, DELO is always ready to meet all adhesive requirements and assist customers in establishing umbrella manufacturing technology worldwide.

Contact HUST Vietnam for more detailed information.

HUST Vietnam is the exclusive distributor of adhesive, dispensing equipment, UV curing lamp, and technology transfer from DELO in Vietnam!