ICA, ACA and TCA adhesives: Classification and applications

17:11 - 04/04/2024

Distinguish between isotropic conductive adhesives ICA, anisotropic conductive adhesives (ACA), and thermally conductive adhesives TCA and typical applications.

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

DELO ADHESIVE FOR GASKETS, CURES IN JUST 3 SECONDS

ICA, ACA conductive adhesives, TCA thermally conductive adhesives, and applications!

Distinguish between isotropic conductive adhesives (ICA), anisotropic conductive adhesives (ACA), and thermally conductive adhesives TCA and typical applications.

In the electronics and semiconductor industries, the use of glue is very common and has become a key factor in determining product quality.

Choosing and controlling the thermal and electrical conductivity of the adhesive is very important, in determining product characteristics, costs, and production productivity.

To better understand DELO's glue product lines, HUST Vietnam will analyze in detail the characteristics of these glue lines.

1. Isotropic conductive adhesives (ICA):

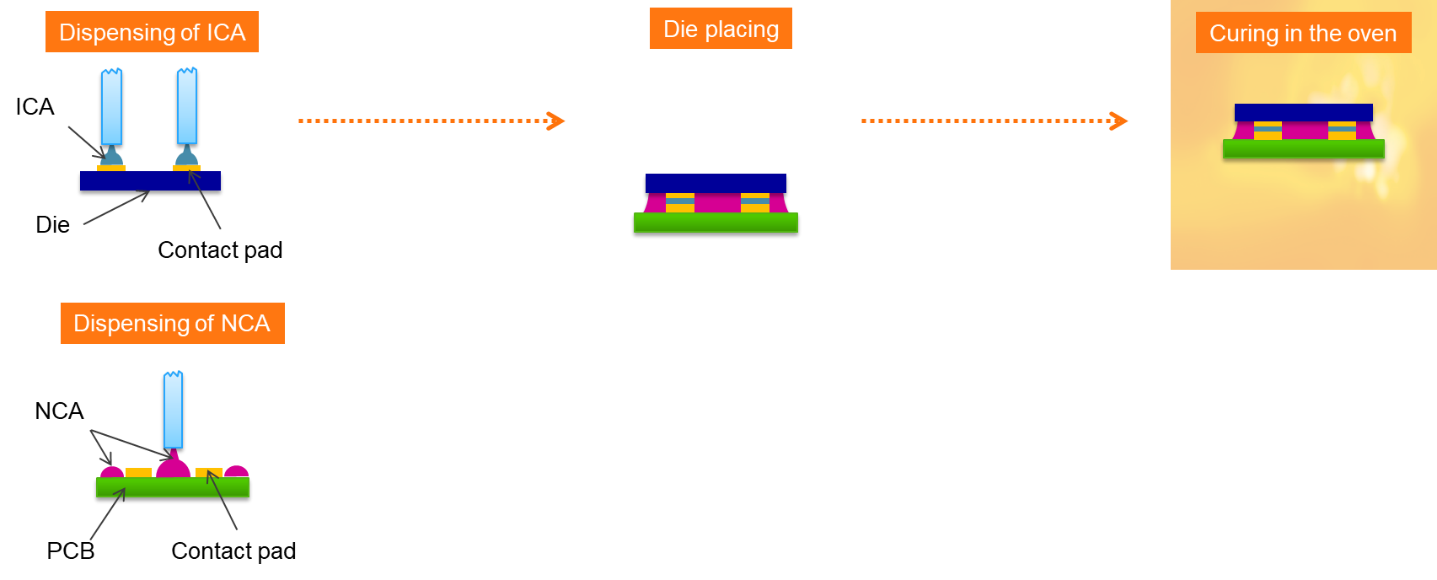

Operating principle: ICA glue is dispersed onto the surface of the contacts (called bumps). The glue contains nano silver (Ag) conductive particles of different sizes.

When pressed with moderate force and cured by heat, the silver particles will come into close contact with each other and connect the contacts, ensuring electrical conductivity of >99%.

Normally, between these contact pins, the area that needs to be insulated will be filled with non-conductive adhesive (NCA) to ensure mechanical bonding.

Electrical conductivity is ensured by the high content of metal particles in the glue.

Dispensing process:

Dispersing glue:

- First, you need to fill in non-conductive adhesive-NCA or use insulating paint to cover the areas that need to be insulated first.

- Then, disperse ICA conductive glue on the areas that need to be conductive.

- Next, place the second component on it, press it gently, and finally put it in the oven at the right temperature.

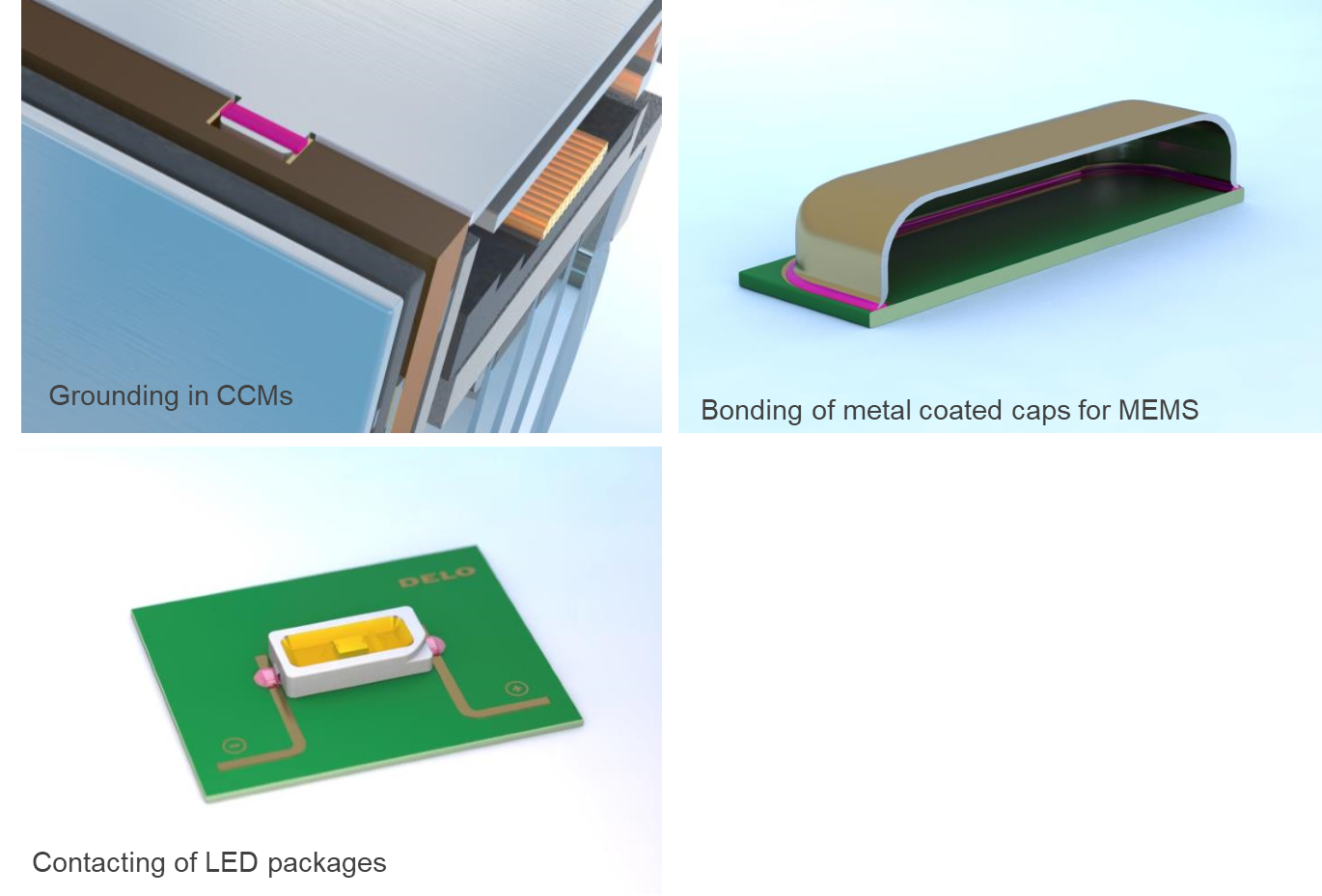

Typical applications:

Many applications require the use of conductive adhesives.

For most applications where the size is extremely small, only a few millimeters, it is not possible to use a mechanical connection such as soldering or screws, forcing the use of glue.

For example: in the camera module of a smartphone, in components in the PCB circuit board, or the adhesion of LED chips of LED lights.

Especially for high-value applications that require aesthetics and adhesive reliability for that product or medical-grade safety features.

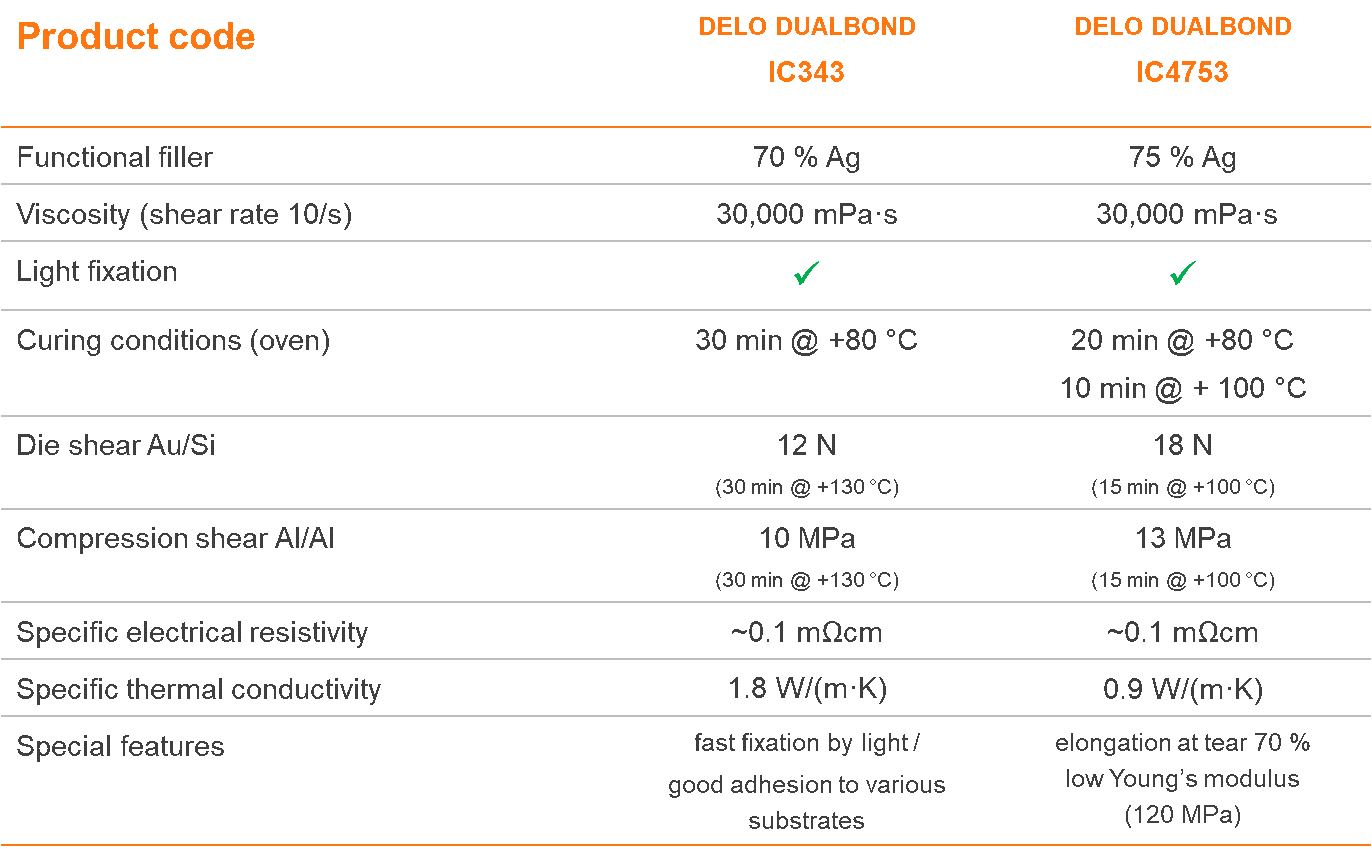

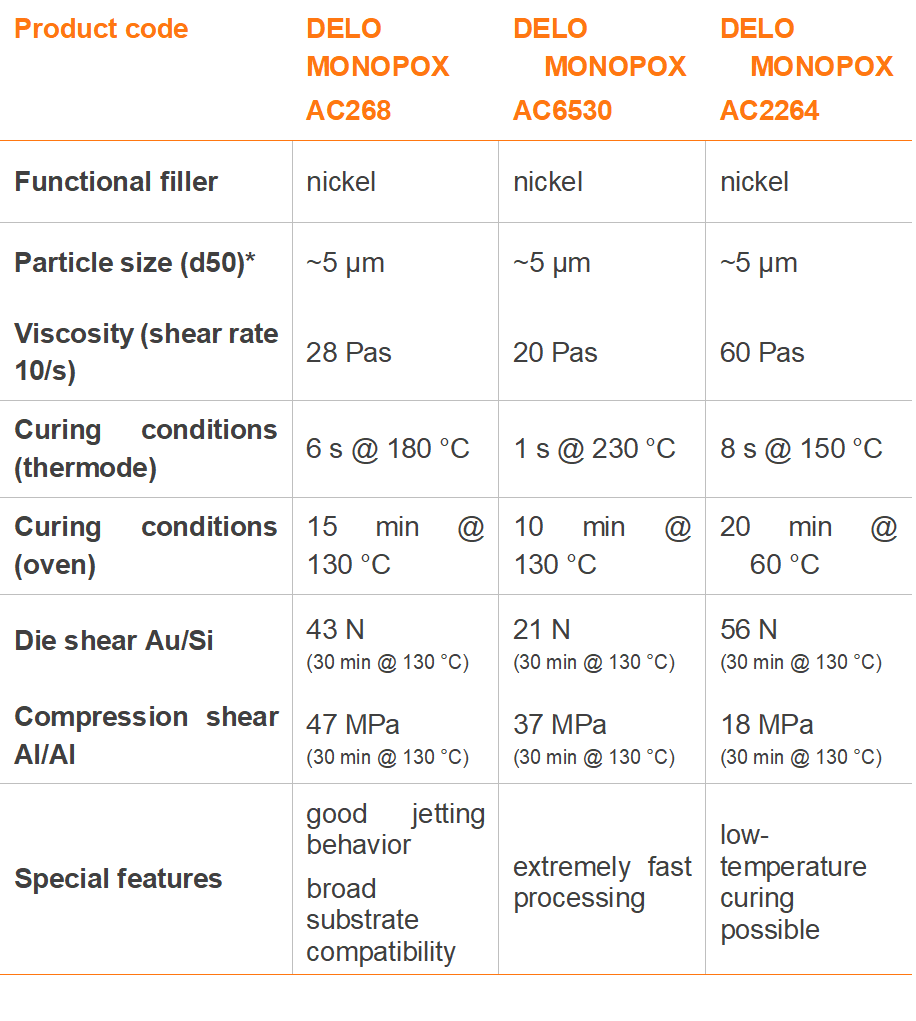

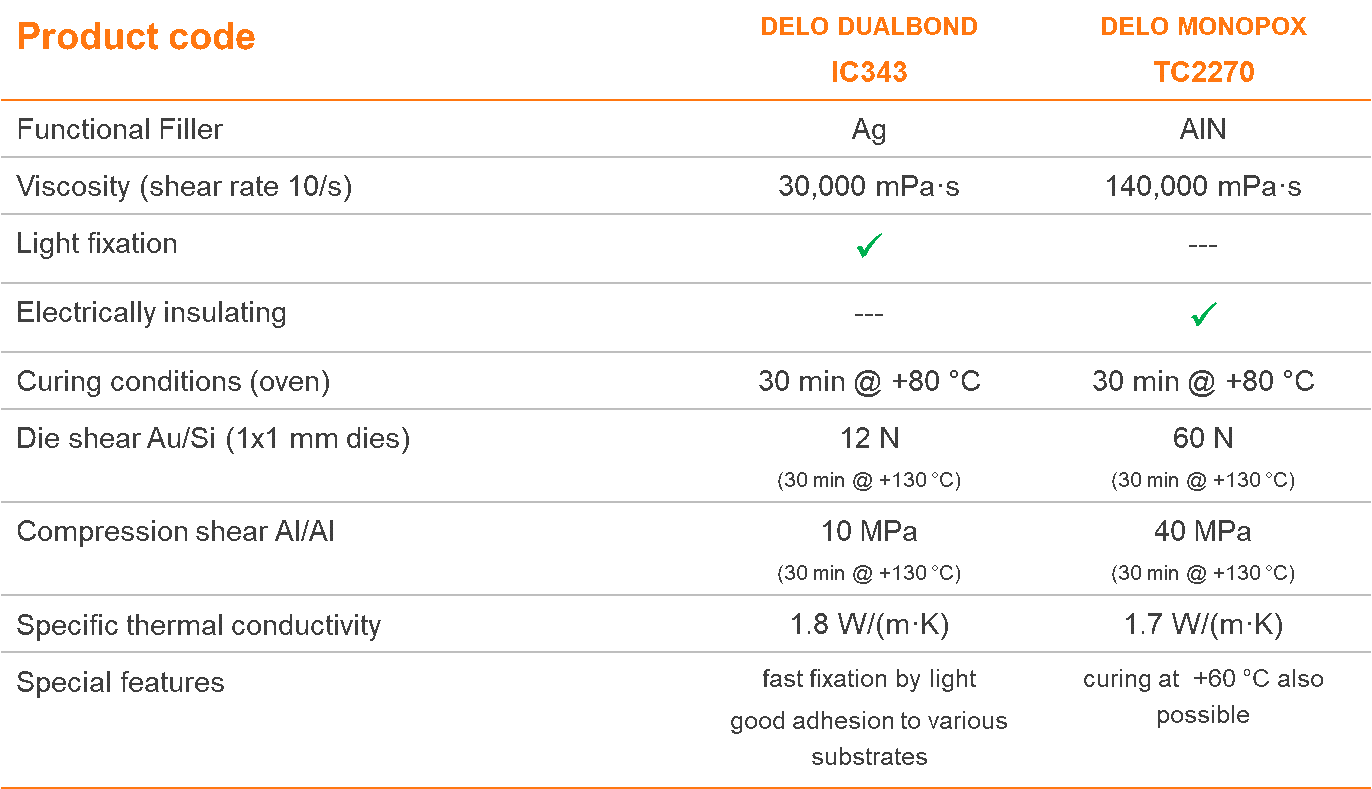

Comparison between DELO's ICA isotropic conductive adhesive brands:

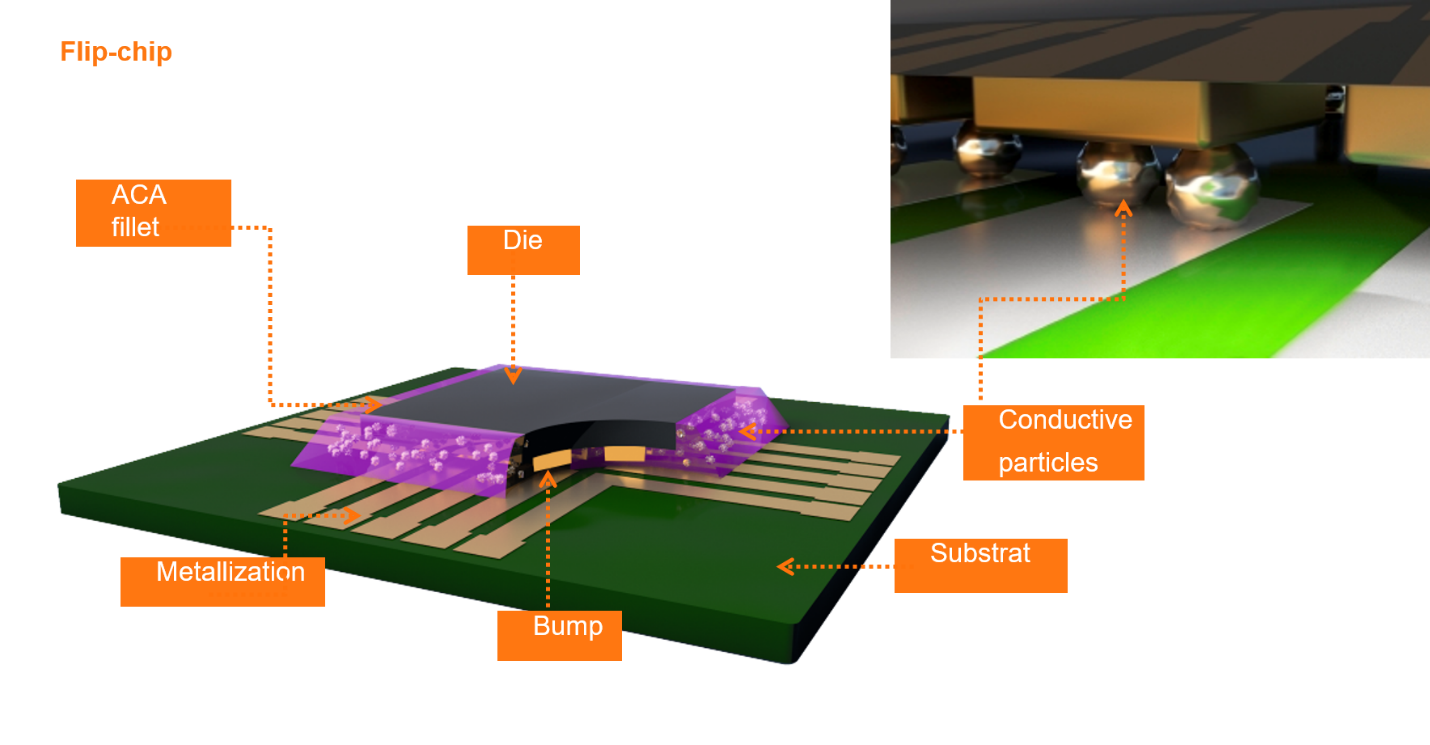

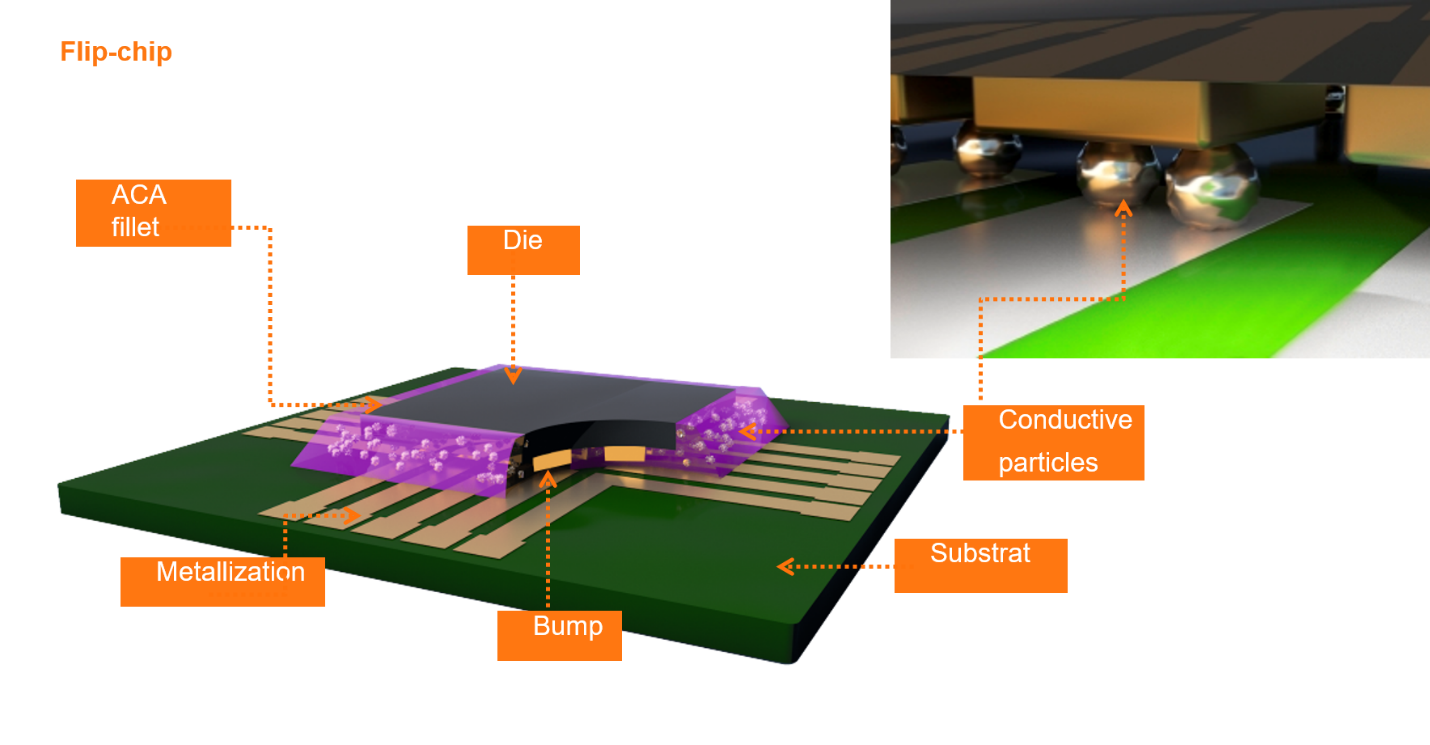

2. Anisotropic Conductive Adhesives (ACA):

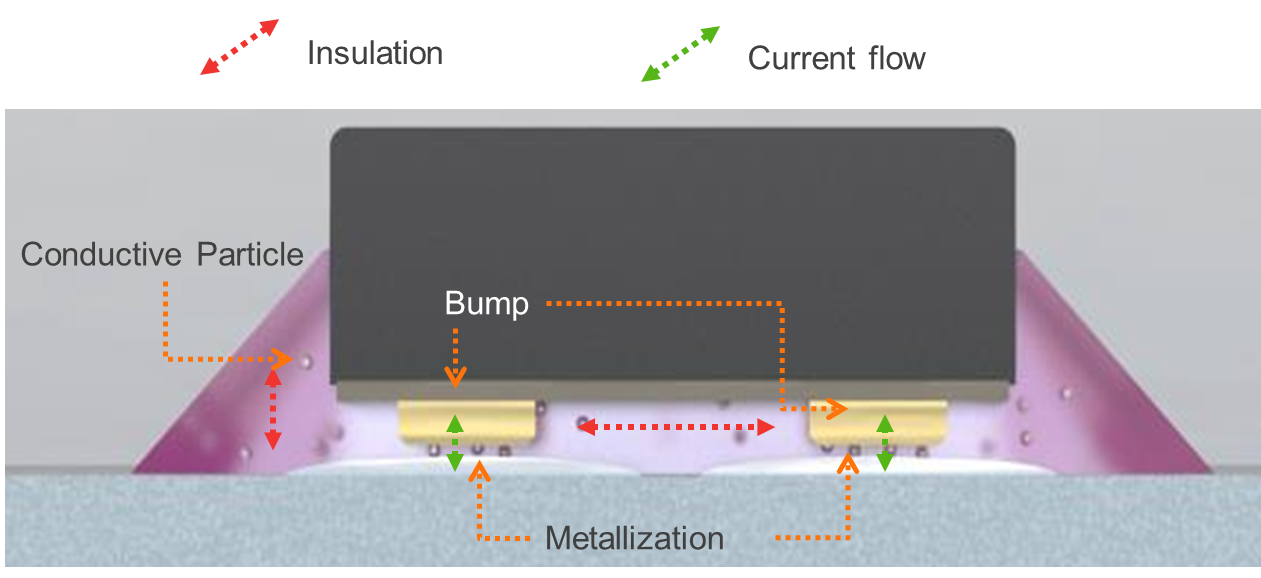

Define: ACA is an adhesive that, after curing, only allows electric current to pass through in a certain direction.

Working Principle:

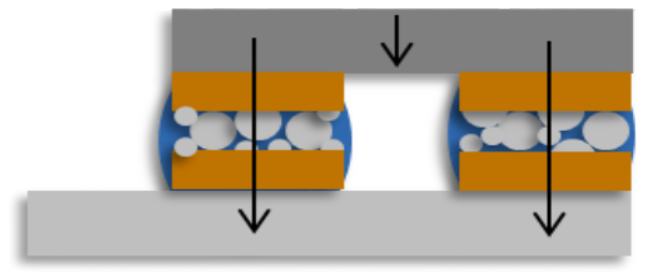

Electric current passes through the adhesive layer in only one direction, due to the similar size of the conductive particles.

The estimated number of conductive particles on a 0.5 x 0.5mm contact is about 20~30 particles, less dense than ICA glue. Therefore, with the heat welding and local pressure pressing method, the Nickel-metal particles will come into contact with the two raised contact surfaces, and the areas that are not pressed with force will cause the glue mass to polymerize by temperature. The liquid will surround the metal particles, preventing them from conducting electricity. Therefore, the current only flows in one desired direction.

Typical electrical conductivity efficiency is usually >95%.

Simulate the adhesion process:

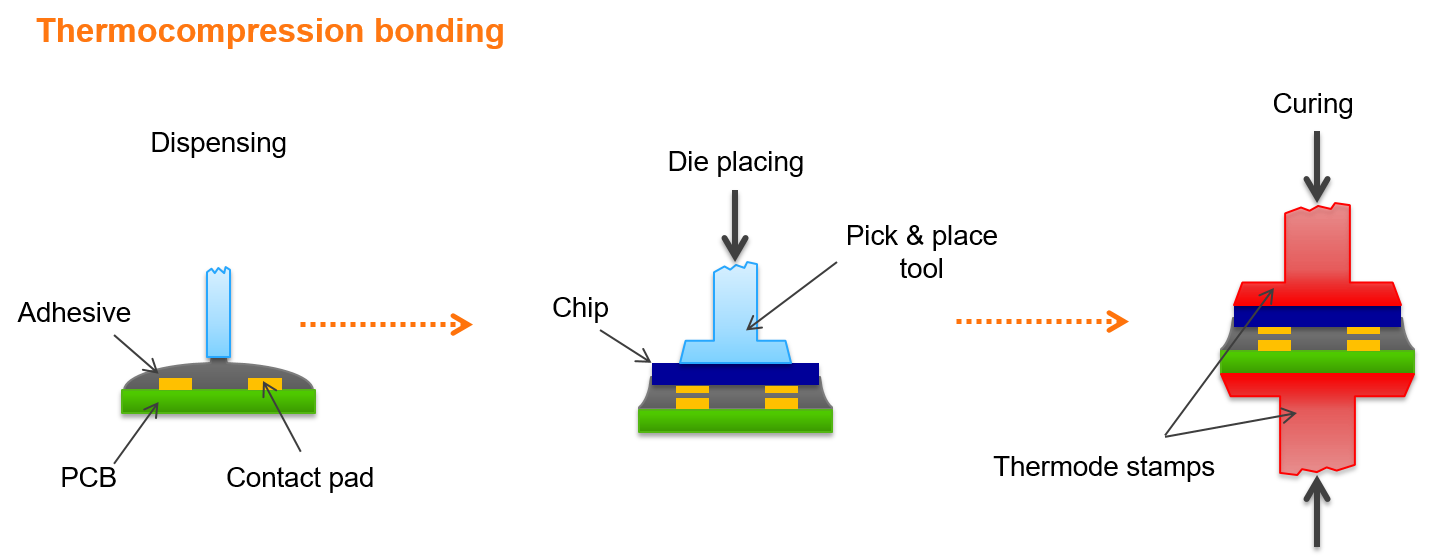

Using high-frequency heat welding head:

Adheres within seconds! ~ 1 – 3 N (for 0.5 x 0.5 mm² chip), +150 to +230 °C.

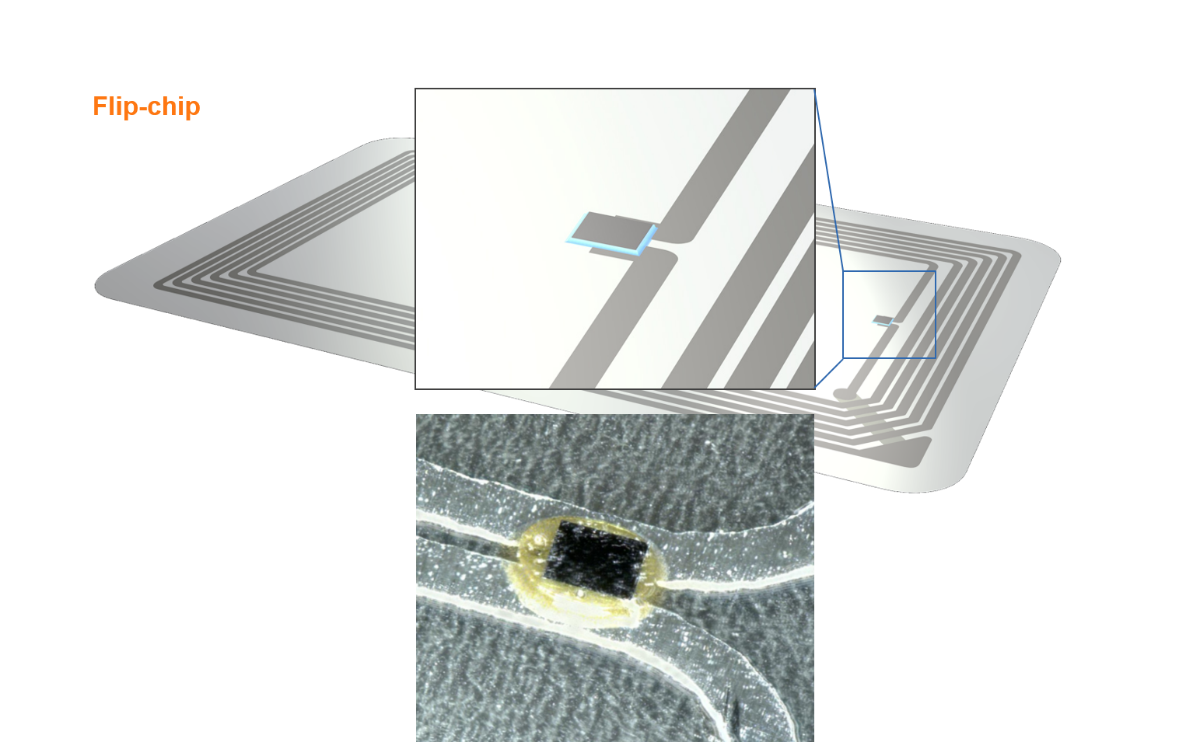

Typical applications in the production of LED chips and RFID flip chips.

Adhesive in RFID magnetic card chip:

Compare DELO's ACAs anisotropic conductive adhesives:

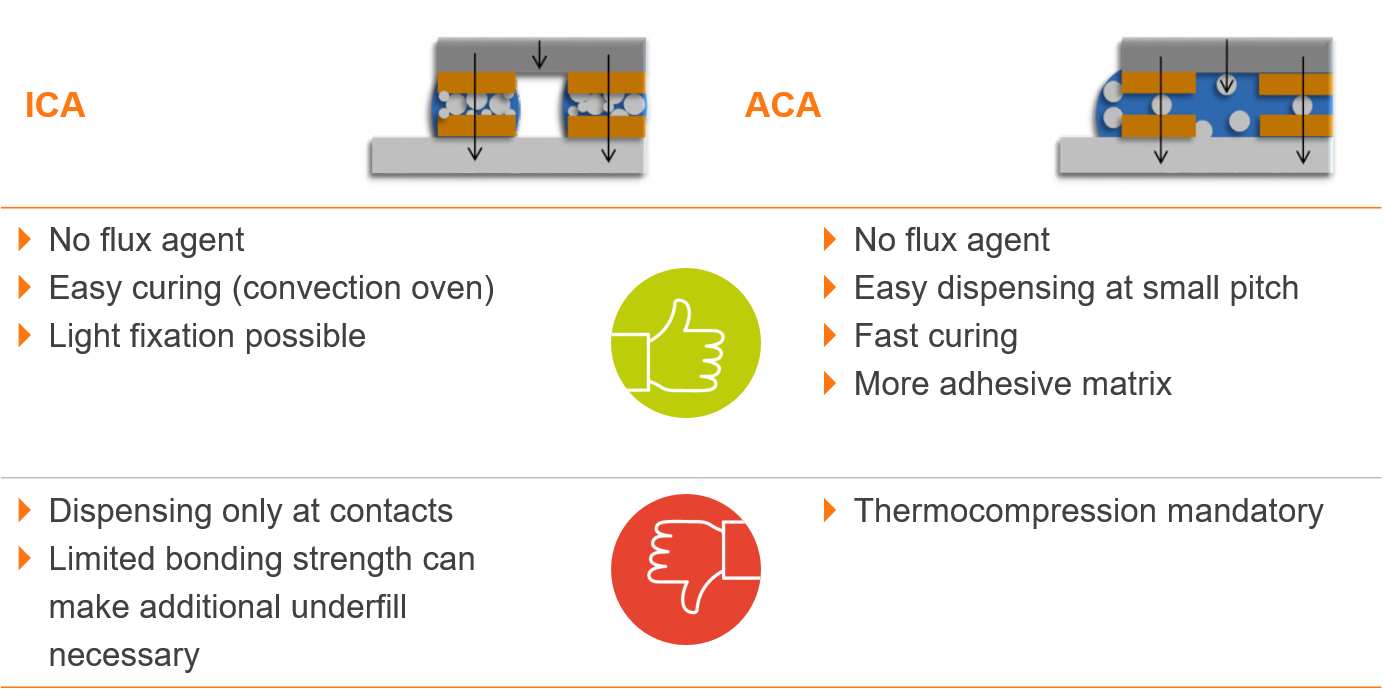

Comparison between ICA glue and ACA glue:

ICA:

- No abrasive agents.

- Easy to cure glue.

- The glue can be fixed with UV light first.

Disadvantage:

- - Glue can only be applied to the position that needs contact. Areas that need to be insulated should avoid applying glue or can be coated with insulating glue first.

- - It may be necessary to add self-filling adhesive (underfill) to increase mechanical properties because the adhesion force is limited by the small contact area.

ACA:

- No abrasive agents.

- Easily disperses glue in small, narrow peaks.

- Fast curing.

- The adhesive block is more durable than ICA.

Disadvantage: Required to use heat sealing tip method.

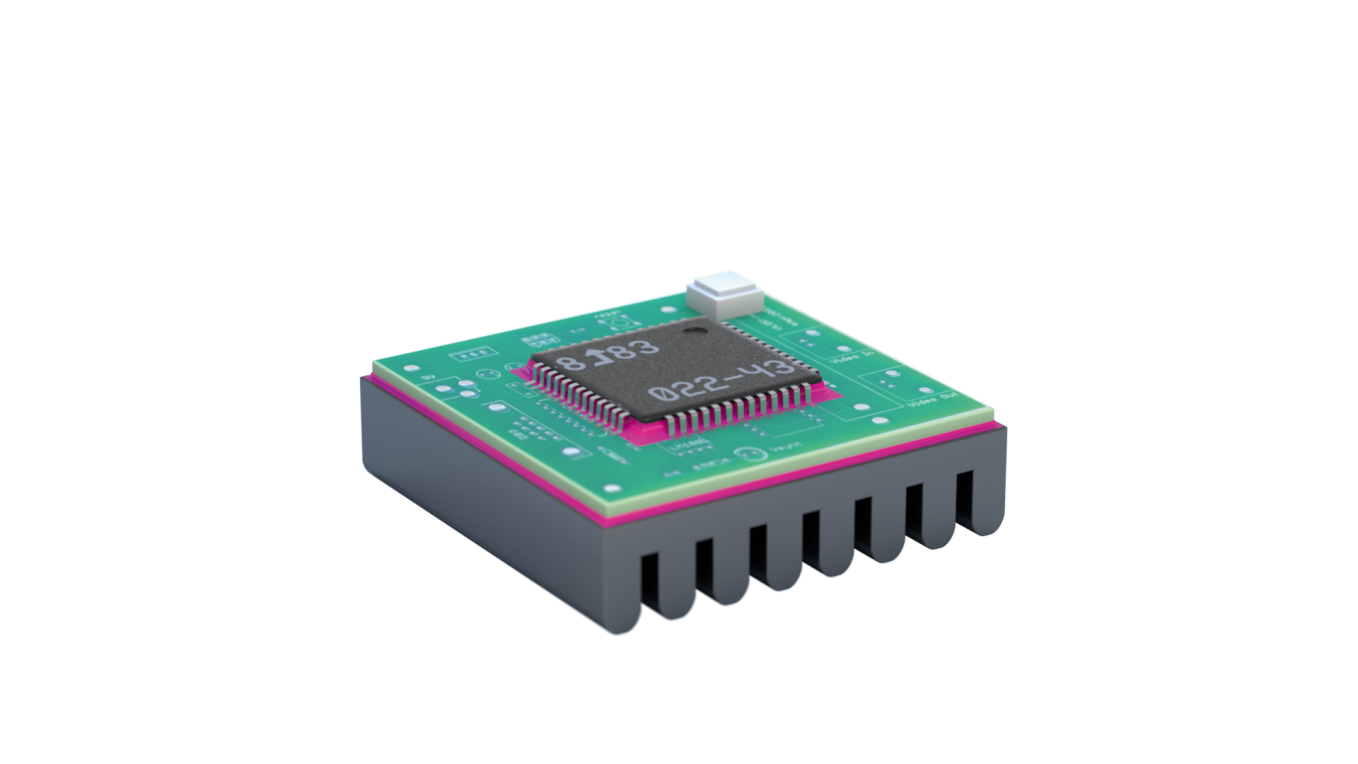

3. Thermally Conductive Adhesives (TCA)

For microelectronic devices.

For applications that require both electrical and thermal conductivity, IC343 adhesive is an ideal choice.

With a typical resistance of only about 0.1 mOhm.cm, equivalent to that of a Chromium alloy. Meanwhile, the thermal conductivity is about 1.8 W/(mK), equivalent to graphite, providing extremely good thermal conductivity.

For applications that require only thermal conductivity and/or electrical insulation, TC2xxx glue is an ideal choice. With filler particles of Aluminum Nitritle (AlN), the glue has a thermal conductivity of 1.7 W/(mK). Nearly 3 times higher than the thermal conductivity of water (0.6 W/(mK)). In addition, the glue can also cure at low temperatures, +60 oC, especially suitable for temperature-sensitive materials.

Application of TCA thermally conductive adhesive in structural adhesion:

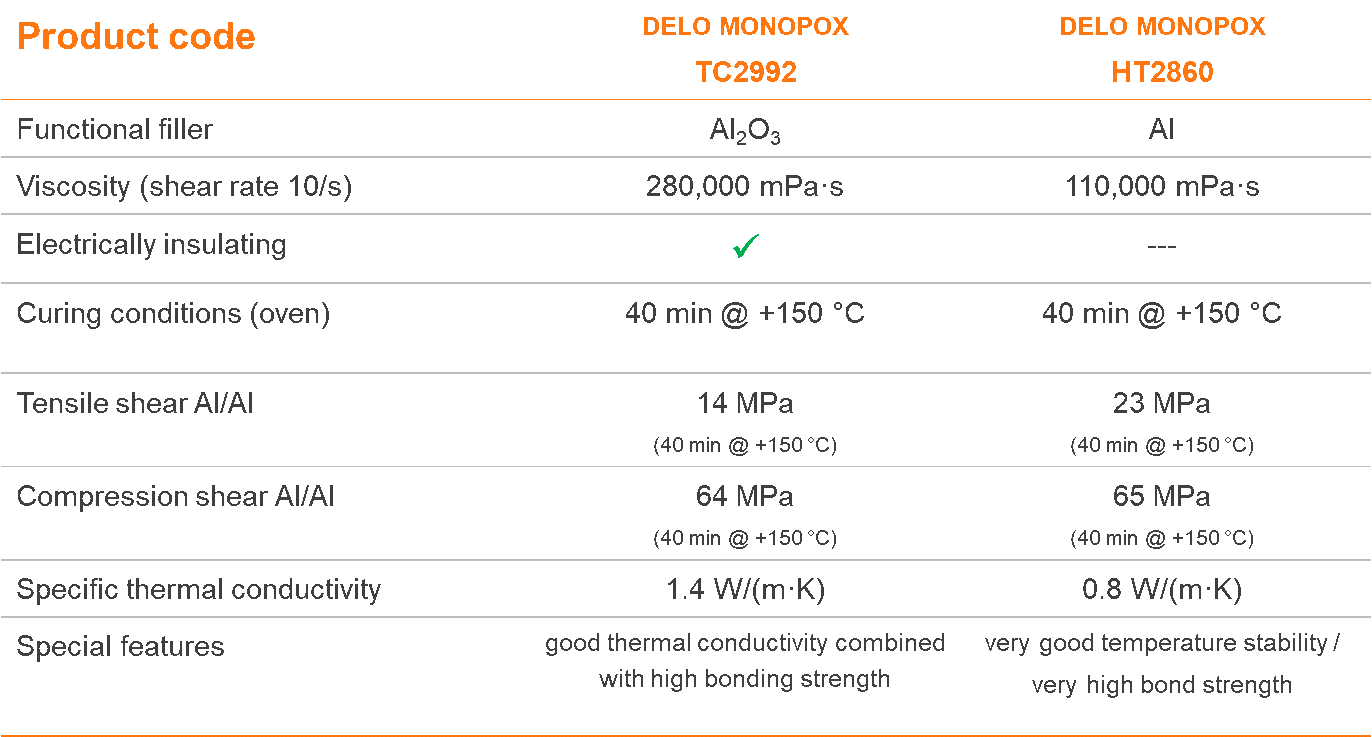

Some typical DELO TCA glues:

Therefore, depending on the application, customers can consider choosing to use conductive glue ICA, ACA, TCA, or non-electrical stretchable glue NCA, to suit the product requirements.

HUST Vietnam is always ready to provide free consultation and assist customers in finding the most suitable glue possible.

HUST Vietnam!