Application of DELO adhesive in production | HUST Vietnam

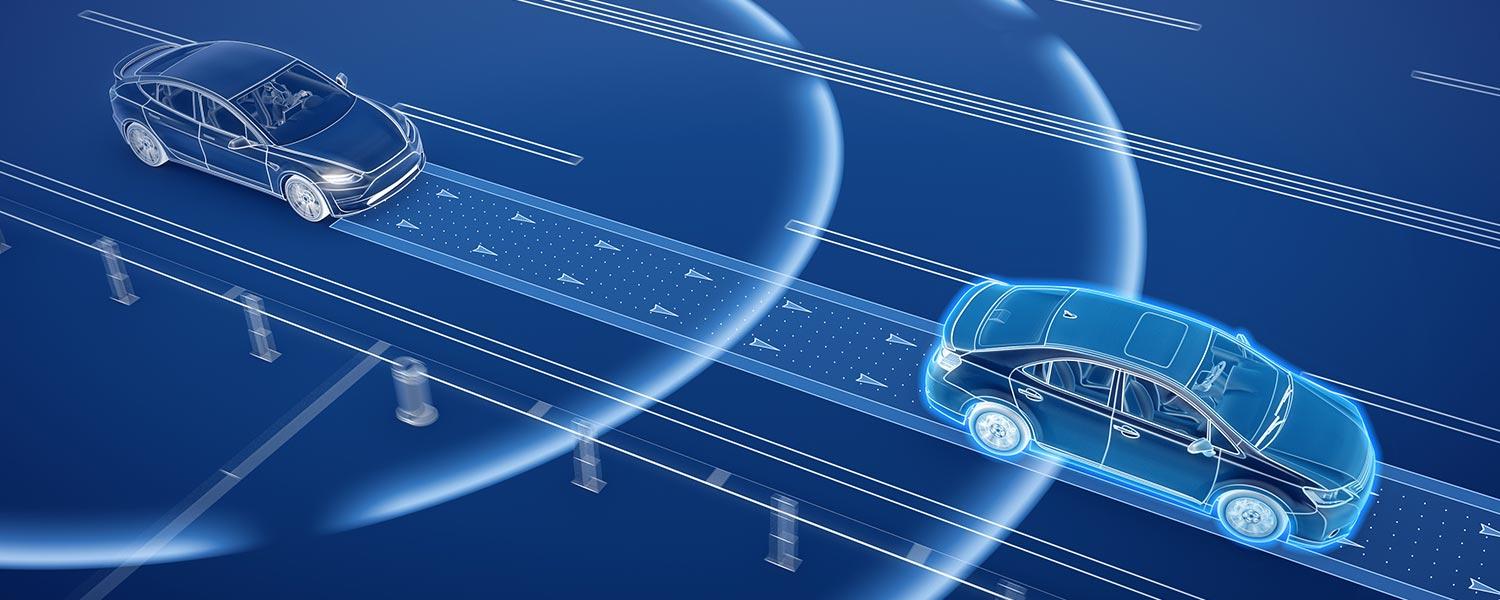

DELO adhesive for autonomous driving technology

Automated driving (Level 3) is considered technically possible thanks to high-performance driver assistance systems (ADAS) and also thanks to innovations in adhesive technology.

Adhesives for cameras and LiDAR sensors;

Adhesives for radar and ultrasonic sensors;

Adhesives and sealants for control devices and plugs.

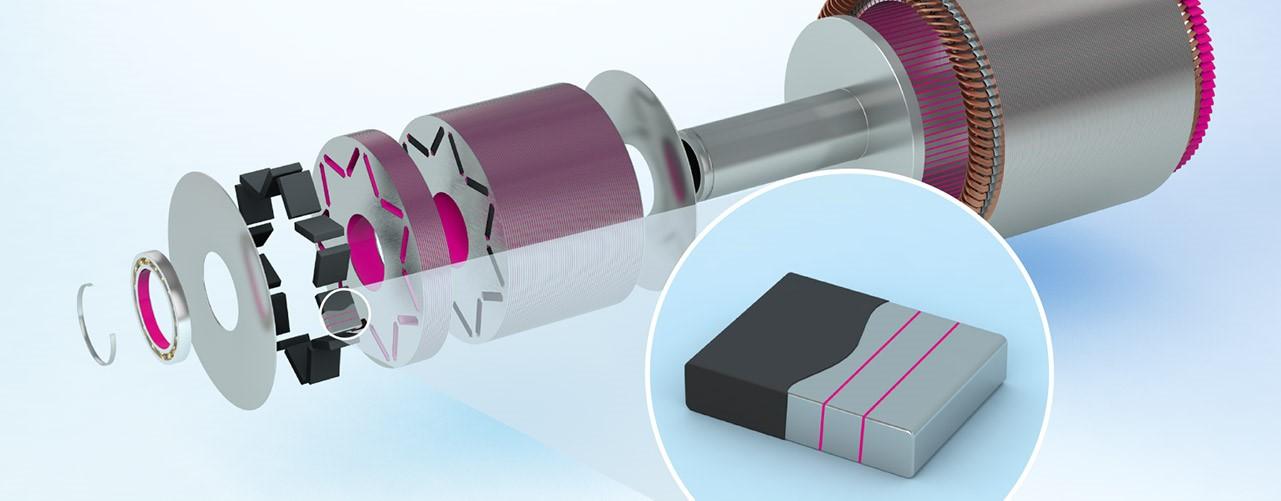

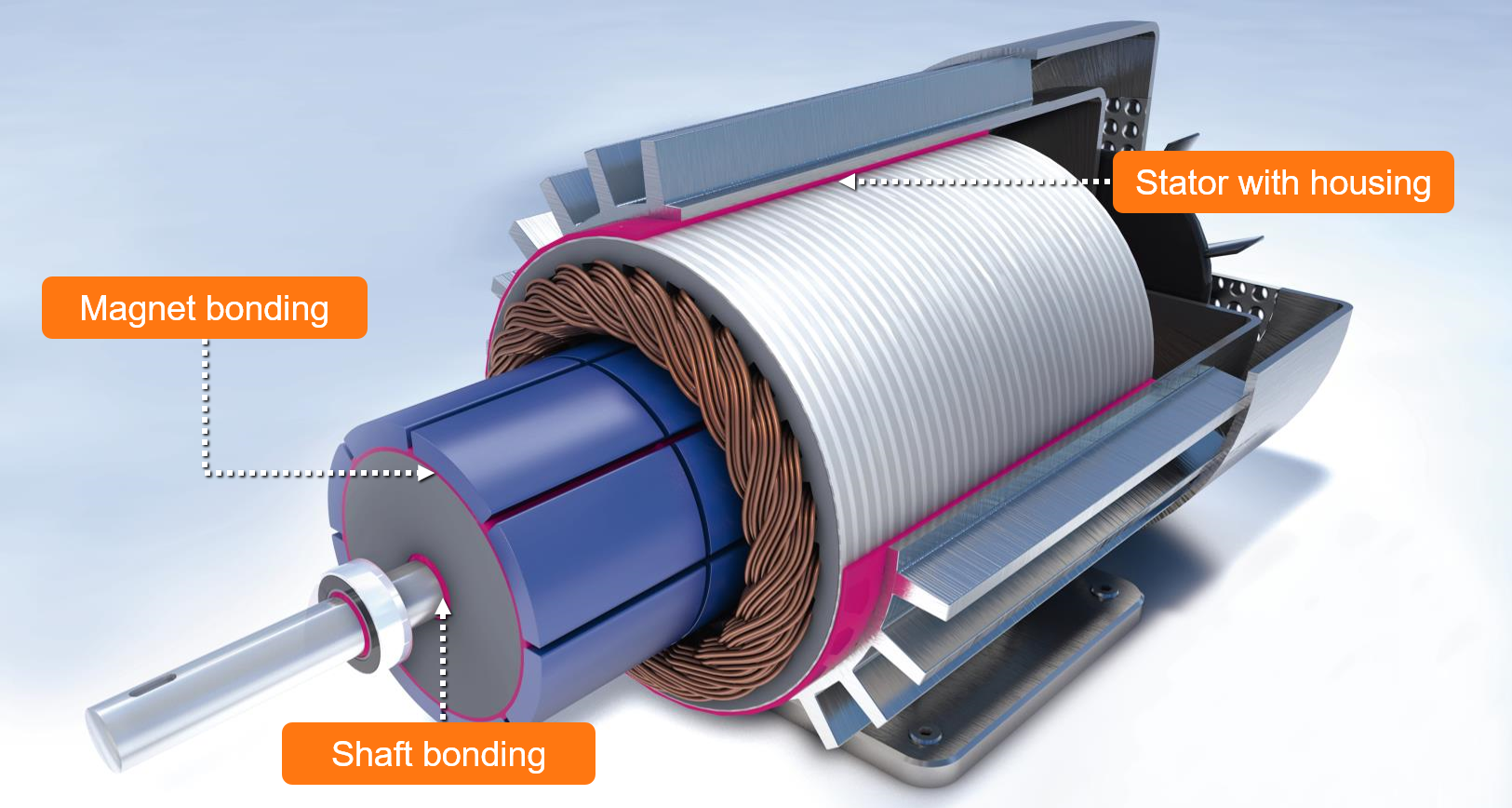

DELO MONOPOX HT2999 - Adhesive for e-motor is thermal-resistant up to 220 oC

This high-temperature adhesive has been optimized for bonding Neodymium magnets in electric motors. The sliding compressive strength of the magnet (NdFeB) is 20 MPa at 180°C. The glued sections remain thermally stable over time. Even after 10,000 hours of testing at 180°C.

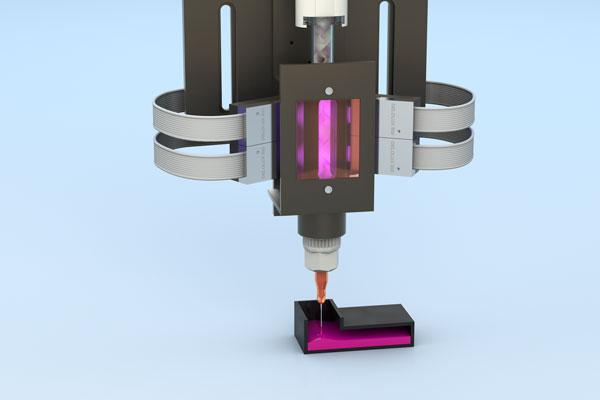

See moreACTIVATION TECHNOLOGY OF UV ADHESIVES BEFORE DISPENSING

DELO-ACTIVIS 600 – Bonds and activates UV adhesive only in 1 step!

UV glue activation technology has been researched and developed by DELO to the world's most advanced level.

This is an especially useful solution when bonding temperature-sensitive electronic components and is shadowed, UV light cannot reach if only U

See moreChoosing the right adhesive for the magnet to housing bonding in E-motor

Today's magnets are usually fixed to the chassis or motor shaft with glue.

Depending on the type of magnet and the specific application and the requirements of the manufacturers, DELO has its own suitable adhesives.

See more

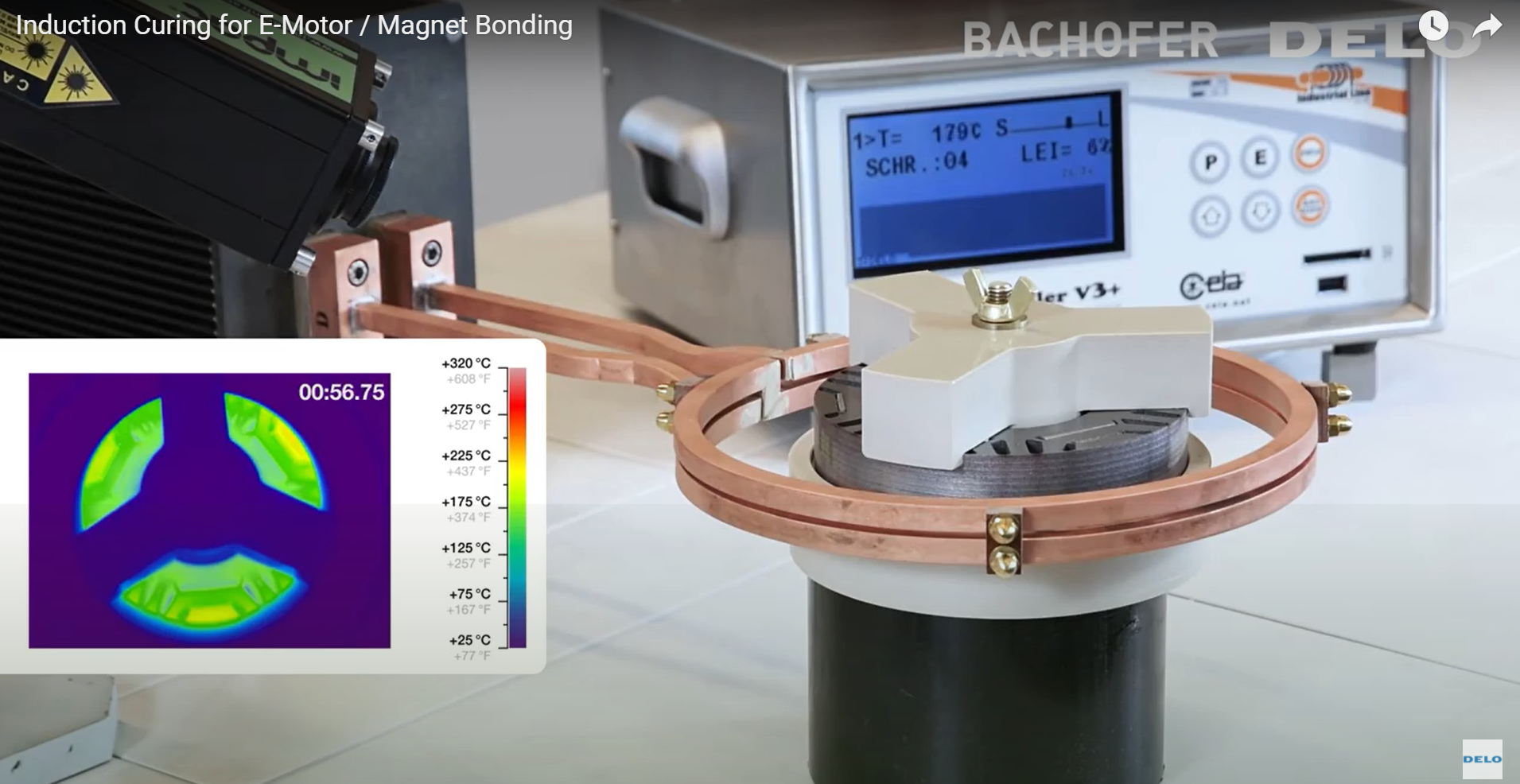

Adhesive curing technology with electromagnetic induction heat

The great ideal solution is that the adhesive will cure within seconds using UV light. But this method only applies to translucent to transparent components, allowing UV light to pass through, and for visible locations, the temperature curing solution is the most optimal.

See more

DELO - ML metal glue is widely apply in electric motors

- DELO ML one-component metal adhesive with high heat resistance and strength – suitable for electric motor assembly;

- DELO ML allows high heat resistance, fast curing in anaerobic conditions when contact with metal ions See more