DELO - ML metal glue is widely apply in electric motors

15:04 - 21/10/2021

- DELO ML one-component metal adhesive with high heat resistance and strength – suitable for electric motor assembly;

- DELO ML allows high heat resistance, fast curing in anaerobic conditions when contact with metal ions

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Introduce:

- DELO ML one-component metal adhesive with high heat resistance and strength – suitable for electric motor assembly;

- DELO ML allows high heat resistance, fast curing in anaerobic conditions when contact with metal ions. DELO ML acts as a screw locking adhesive, filling any thread and surface locking gaps;

- The product is suitable for coaxial metal joints. Using visible light and UV curing glue helps fasteners cure even in hard to reach areas in seconds;

- Ingredients: Modified Urethane acrylate, 1-component glue, solvent-free.

- Using temperature range: - 60 0 C ~ 180 0 C.

- RoHS standard 2015/863/EU, passed test method UL 94 HB.

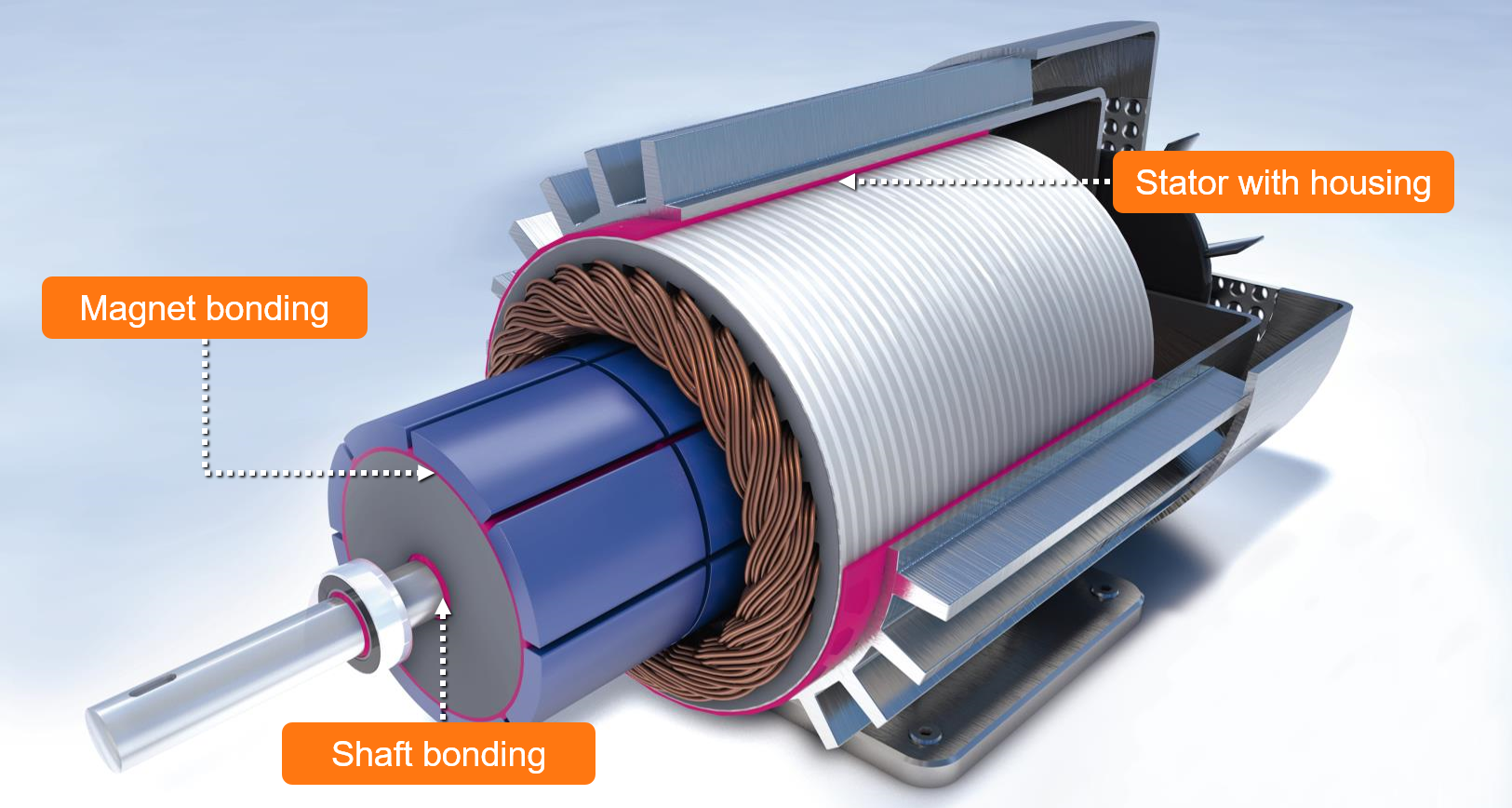

DELO-ML glue is used a lot in bonding parts of electric motors (Photo DELO)

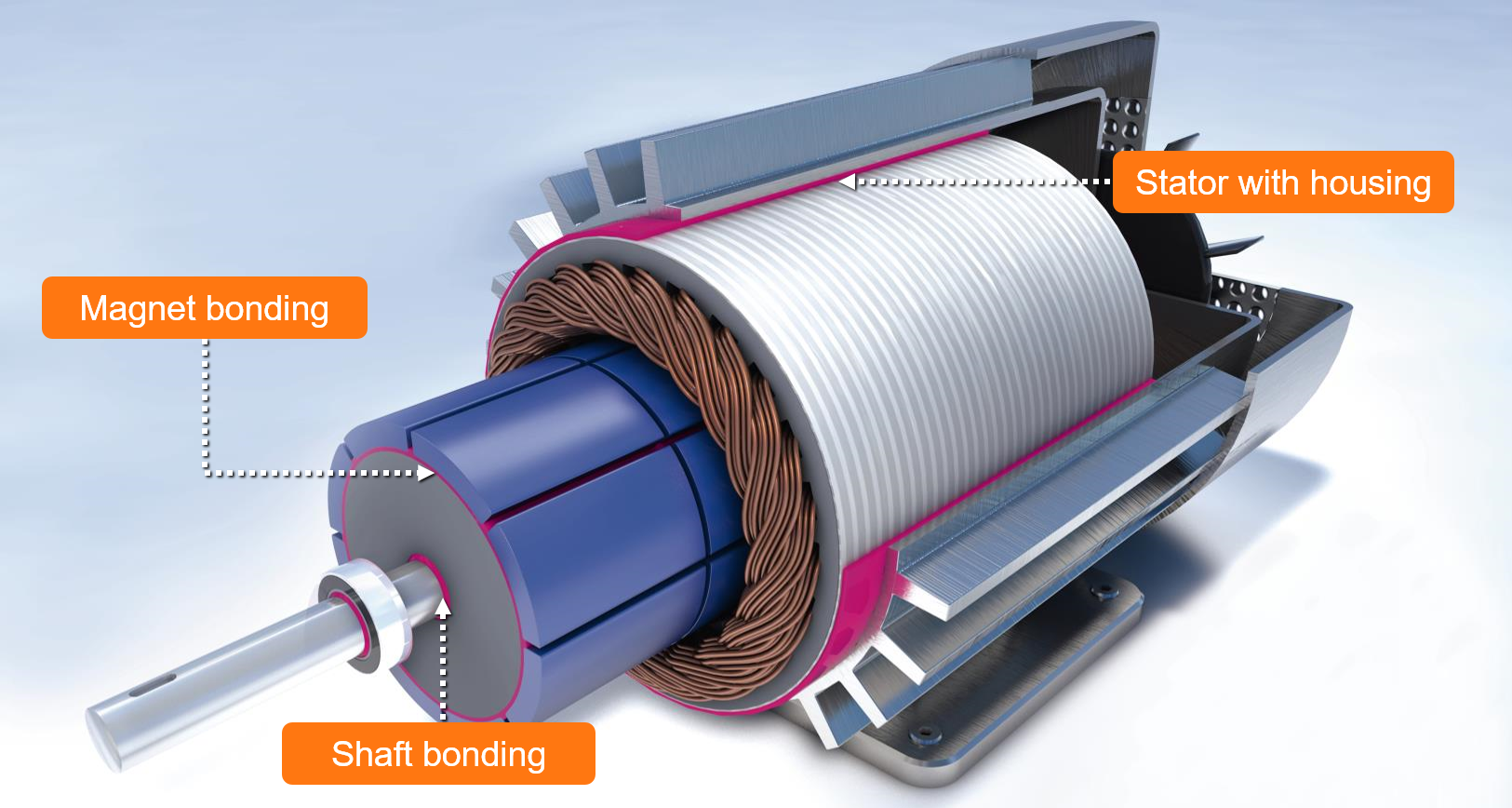

Application:

DELO ML is very flexible, with uniform pressure resistance, suitable for metal-glass, metal-plastic joints.

Applications of DELO ML include:

- Shaping, tightening coaxial connections;

- Screws on materials without drilling;

- Mounting pipes, bolts, metal joints;

- Glue for the industries of engine manufacturing, automobile assembly, consumer electronics assembly, mechanical engineering;

- High strength adhesive for coaxial, rack, or socket mounting;

- The bonded surface needs to be clean from dust, grease, recommend DELOTHEN products to get the most perfect surface;

- The adhesive should be used in conjunction with DELO's dedicated dispersant that is compatible with anaerobic curing adhesives;

- The adhesive has a low viscosity, the visible border of the glue can use light to cure. The adhesive has high strength, is difficult to remove, good adhesion even to surfaces with low roughness.

DELO-ML is also widely used in other metal bonding applications (Photo DELO)

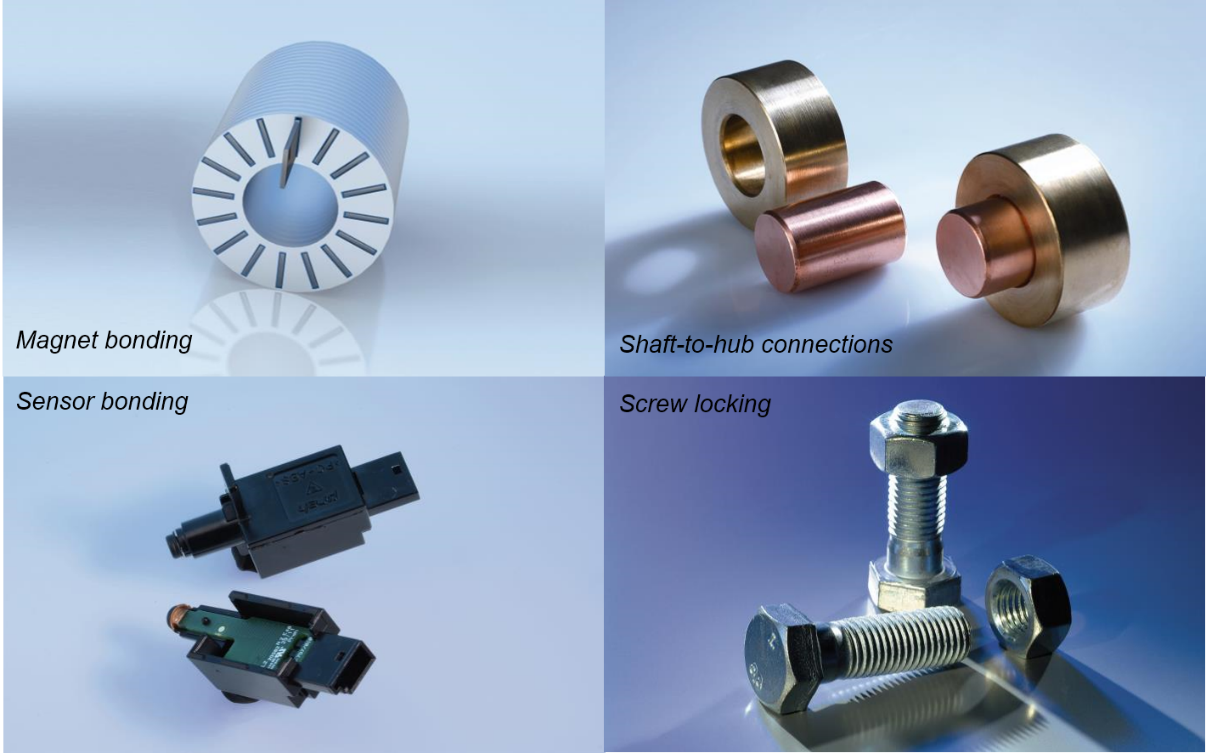

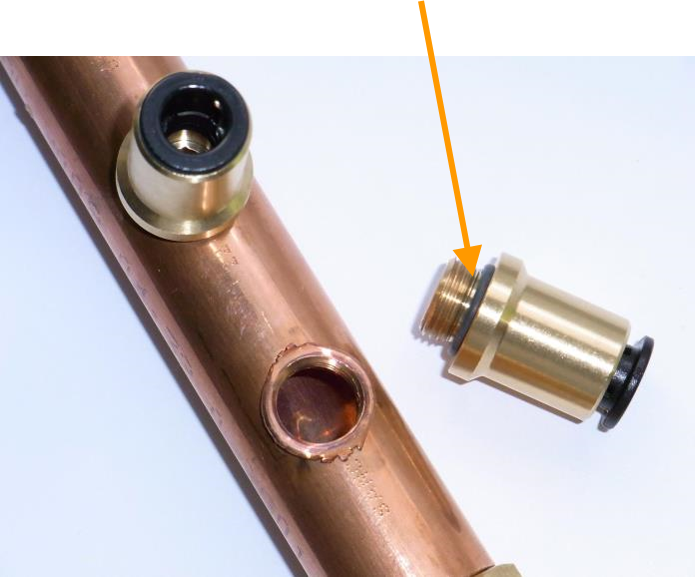

- Thread lock, vacuum seal threaded joints, pipes with DELO-ML 5849 glue

Application in pipeline connections with compressed air, refrigerant gas, water, oil, ...

Glue is manually applied directly from the 200ml glue bottle to the thread of the connector, then screwed tightly, heated to speed up the curing of the glue or can be left to dry naturally within 1 hour to achieve a relative tensile strength ( ~ 10 MPa) or let cure completely after 24h.

Ingredients material:

- Branching Connector: Brass,

- Main air pipeline: Copper.

|  |

| Branching connector on gas pipeline | |

Test requirements:

- Tightness test (water);

- Use temperature range: max. 50°C warm water;

- When the connectors are tightened, the glue is only intended to prevent loosening and seal;

- The glue can be easily removed when you want to remove it.

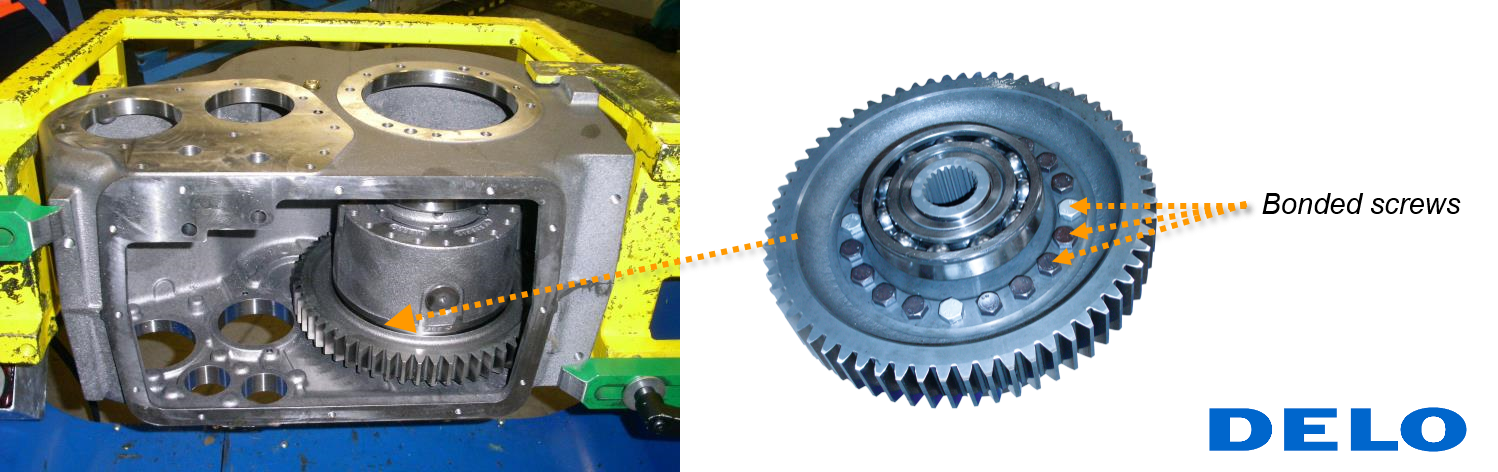

- Fix the bolts of the reducer gear

Thread these bolts with DELO-ML 5327 glue.

During the operation of the gearboxes of agricultural machines, construction machines, etc., the oil will heat up, the screws and adhesives must be resistant to the hot oil at temperatures up to +90 ° C and must be stable in an oily environment.

Material Composition:

- Bolts: steel;

- Gear: cast iron.

Requirements and test properties of glue:

- Preferred 1-component adhesive;

- The shelf life of glue (after opening) is long (days to weeks);

- Good solvent resistance;

- Environmentally friendly, non-toxic.

In addition to meeting the above requirements, DELO glue also offers a number of other advantages such as:

- Easy to manipulate and handle glue stains;

- Easy to apply glue directly from the glue bottle;

- Glue can be used for many purposes of gluing metal;

- High heat resistance.

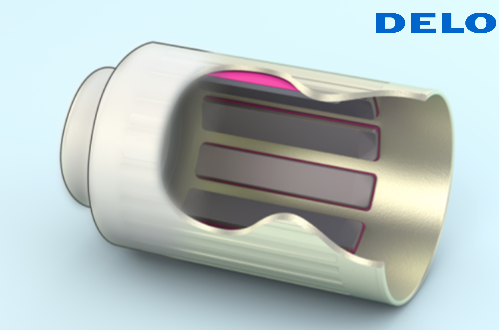

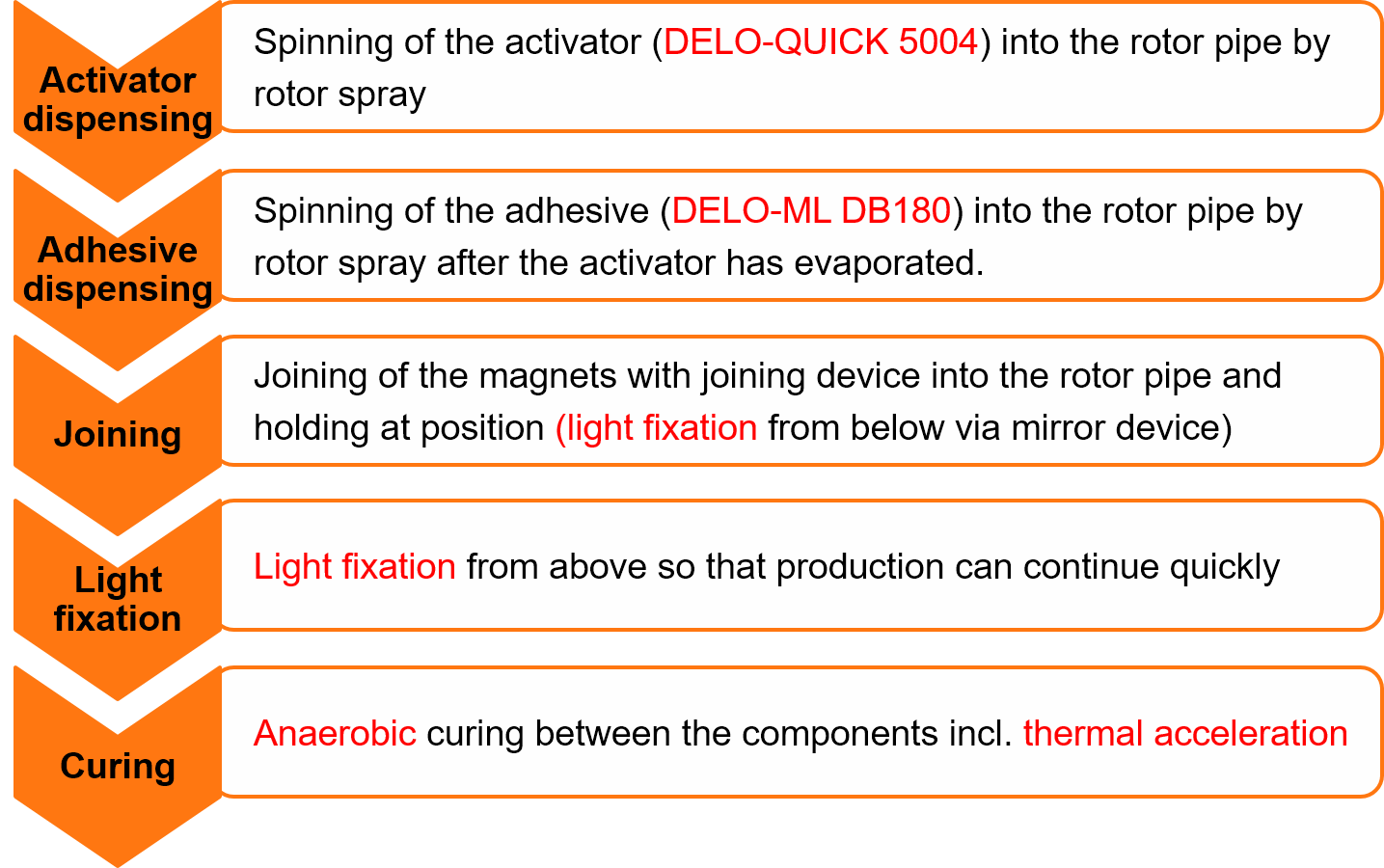

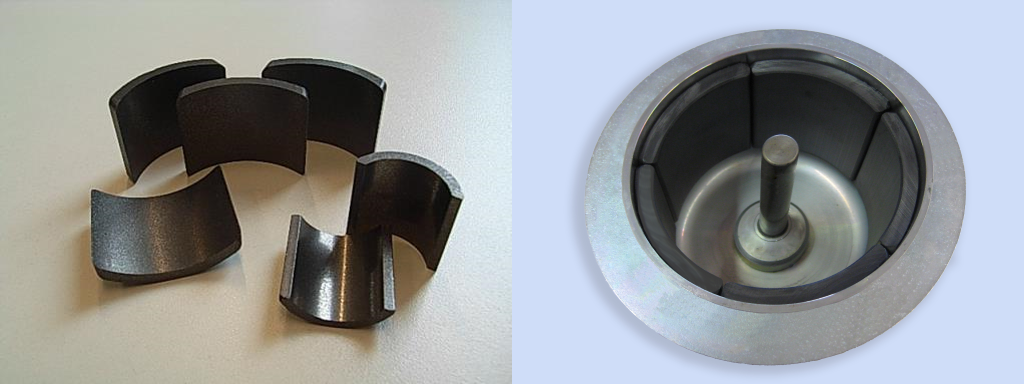

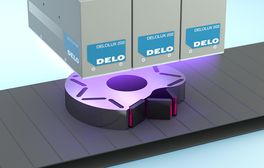

- Bonding magnets in electric car engines of EBM-Papst with DELO ML DB180 adhesive

There are many ways to arrange the magnets on an electric motor, can bond the magnets on the motor housing, coils fixed to the shaft, and use commutator brushes to contact power transmission. Or you can fix the magnet to the rotating rotor and the coil is fixed to the chassis.

In the above cases, the magnets need to be fixed to the steel frame to create certainty and prevent movement while the motor is operating.

Material Composition:

- Rotor: E235 tube steel, plated or passivated.

- Magnet: NdFeB , passivation type.

Use ML DB180 glue in combination with QUICK-5004 activator.

The requirements and parameters of the glue test passed:

- Prefer 1-component glue;

- Fix the magnet to the steel rotor (rotation speed up to 1,500 1/min);

- Operating temperature range: -40 °C to +120 °C;

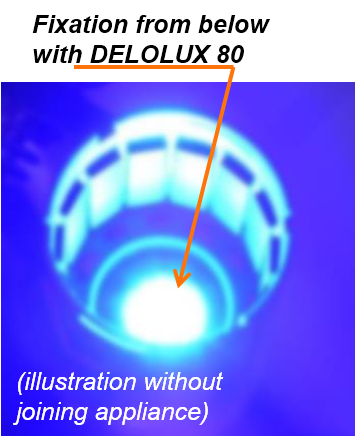

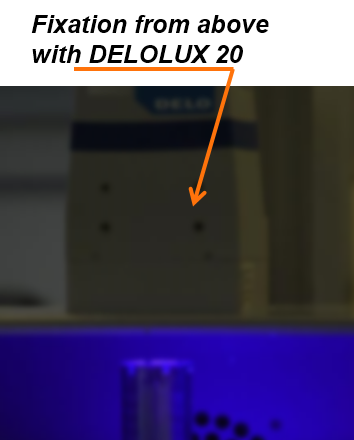

- High yield with curing time < 10 s using DELOLUX 80 & 20 UV lamp;

- Good traction between flat and smooth surfaces;

- Thermal shock test: -40 °C to +85 °C, 500 cycles, 30 minutes each half-cycle;

- Tear strength > 500 N at room temperature.

Experient process:

|  |  |

| UV light from below to fix the magnet | UV irradiation from the top to cure the glue | UV lamp DELOLUX20 |

For conventional motors, using ferromagnetic ferrite magnets and the motor housing is galvanized steel, DELO-ML DB133 glue can be used.

Light curing adhesive by DELOLUX 20/50/80 wavelength of 365nm.

|  |  |

| Normal electric motors and ferrite magnets | DELOLUX 80 | DELOLUX 20 |

Specifications of popular DELO – ML glue codes

Specifications | DELO-ML Anaerobic Adhesive (Metal Light) | |||||||

DB133 | DB135 | ML DB140 | DB154 | DB180 | ML 5327 | UB160 | ||

Ingredient | Modified Urethane acrylate | Modified urethane methacrylate ester | ||||||

Color (for 1mm thick glue that has cured) | Transparent, colorless | Yellowish, transparent | Yellowish, transparent, fluorescent | Yellowish, transparent, fluorescent | Yellowish, lightly translucent, fluorescent | Green | Green | |

Density (g/cm 3 ) | 1.1 | 1.1 | 1.09 | 1.1 | 1.1 | 1.1 | 1.1 | |

Viscosity (mPa.s) | 730 | 1200 | 900 | 6000 | 17000 | 300 | 10000 | |

Activator | DELO-QUICK 5002 | DELO-QUICK 5006 | DELO-QUICK 5006 | DELO-QUICK 5002 | DELO-QUICK 5004, 5006 | DELO-QUICK 5002, 5006 | DELO-QUICK 5006 | |

The temperature in use range ( o C) | -40 ÷ +150 | -60 ÷ +180 | -60 ÷ +180 | -60 ÷ +180 | -60 ÷ +180 | -60 ÷ +200 | -60 ÷ +200 | |

UV wavelength (nm) | 365 nm | 365, 400 nm | 365, 400 nm | 365, 400 nm | 365, 400 nm | - | - | |

UV irradiation time (s) | 25s, 60mW/cm2 | 10s, | 10s, | 6s, | 10s, | - | - | |

Initial curing time | 3 ~ 6 min | 2 ~ 4 min | 1 ~ 3 min | 2 ~ 4 min | 5 ~ 10 min | 2 ~ 4 min | 2 ~ 4 min | |

Final curing time | 24h | 24h | 24h | 24h | 8h | 20 min | - | |

Off-torque (Nm) | No torque | 30 Nm | 30 Nm | - | 34 Nm | 60 Nm | 50 Nm | 40 Nm |

Momen M=46 Nm | - | 60 Nm | - | 65 Nm |

| 70 Nm | 70 Nm | |

Compression shear strength (MPa) | Glass/ glass | 30 | 30 | 30 | 11 | 16 | - | - |

PA6/ Stainless steel | 10 | 10 | - | 6 | 10 | - | - | |

PA6 / PA6 | 18 | 16 | - | 7 | 15 | - | - | |

Steel shaft/ steel hub | 28 | - | 40 | 35 | 40 | 33 | 40 | |

Tensile shear strength (MPa) | Al/Al (sandblasted, after 72h curing) | 12 | 13 | 6 | 13 | 13 | 11 | 8 |

Steel/Steel (sandblasted, after 72h curing) | 14 | 16 | 13 | 16 | 14 | 16 | 14 | |

Tensile strength (MPa) | 20 | 30 | 40 | 60 | 30 | - | - | |

Elongation at tear (%) | 130 | 30 | 30 | 4 | 35 | - | - | |

Young's modulus (MPa) | 300 | 900 | 900 | 3000 | 1000 | - | - | |

Shore hardness | D 44 | D 70 | D 74 | D 84 | D 70 | - | - | |

Glass transition temperature ( o C) | 104 oC | 110 oC | 120 oC | 110 oC | 90 oC | - | 133 oC | |

Coefficient of thermal expansion (ppm/K) | 100~150oC: 184 ppm/K | 95 – 150oC: 203 ppm/K | 100–160oC: 179 ppm/K | - | 30-150oC: 195 ppm/K | - | - | |

Shrinkage (%vol.) | 8.6 | 7.7 | 8.7 | 8.4 | 7.8 | - | - | |

Water absorption (%wt) | - | 1.03 | 0.8 | 0.7 | 1.1 | - | - | |

Volumetric Resistance (Ohm.cm) | 1x1016 | 3x1016 | - | - | - | - | - | |

Surface Resistance (Ohm) | 1x1014 | 2x1014 | - | - | - | - | - | |

Dielectric constant (RF-IV method, 1 MHz) | - | 2.8 | - | - | - | - | - | |

Creep resistance (CTI M) | >600M | >600M | - | - | - | - | - | |

Storage (with an unopened container) | 9 months at 0-10 o C, 6 months at 25 ° C | 6 months at 0-10 o C, 3 months at 25 ° C | 6 months at 0-10 o C, 3 months at 25 ° C | 6 months at 25 ° C | 6 months at 0-10 o C, 6 months at 25 ° C (for vials ≤900ml) | 12 months at 0-10 o C, 6 months at 25 ° C | 6 months at 25 ° C (for vials ≤600ml) (glue lifetime 4 weeks after opening) | |

Contact HUST Vietnam for more detailed information.

HUST Vietnam is proud to be the exclusive distributor of glue, dispensing equipment, UV curing lamp, and technology transfer from DELO in Vietnam!