7600 X-Ray Inspection Machine Supplier for IC Semiconductor

X-Ray inspection system is high-precision detection equipment. It inspects and analyzes the inner structure of the object without damage via the penetration power from X-Ray.

It has been widely applied to BGA detection, LED, SMT, IC semiconductor, battery, automotive electronics, ceramic products, casting, plastic, connectors, 2.5D image analysis, pharmaceutical products and other industries.

A Leader in the Intelligent x-ray Detection Equipment 15 years experience in SMT field, Makes us understanding the customers’ demand and requirement very well!

–Inspection of internal cracks and Defects analysis of internal conditions (Analysis of internal displacements)

Youtube Demo: X-Ray Inspection Machine Supplier for IC Semiconductor

- SMT/Semiconductor/Solar/Connector/LED

- High-definition image: Slanting/Bridge/Voids/Cold Solder/Bonding wire

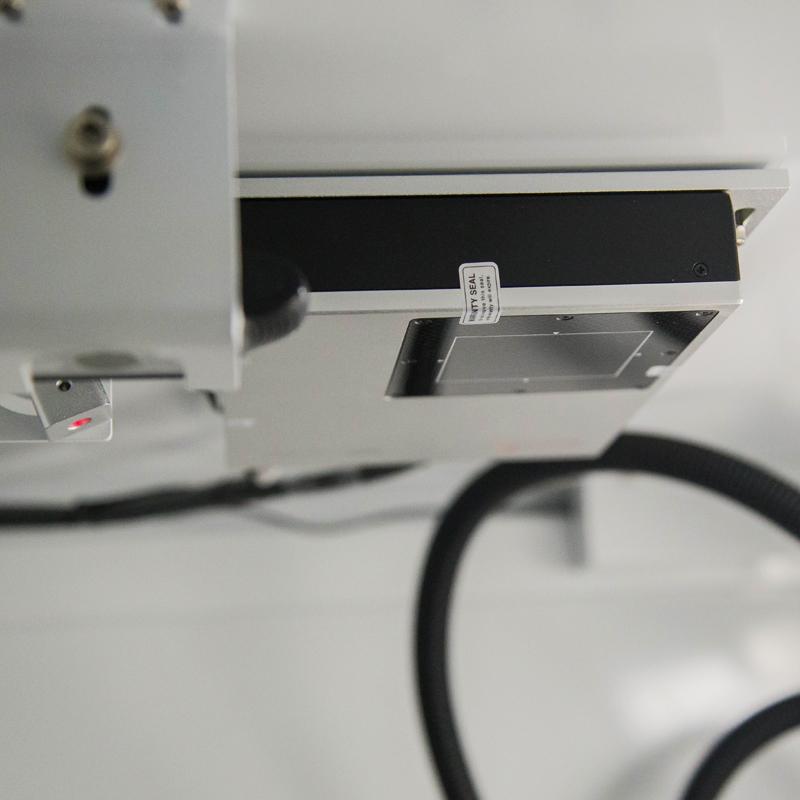

- 100KV 3um (130 KV Optional)closed X-ray tube,long life time,maintenance in free

- 2.3 mllion high resolution digital flat panel detector

- 6 axis linkage system.

- 60 degrees observation

- Platform 360° rotation

- Color lmage Navigation & Mapping Navigation

- Mapping Mosaic Function.(optional )

- Scalable 3D module(industrial CT) (optional)

- Programmable Detection.(optional)

Application

1) Defect inspection in IC encapsulation, e.g.: layer separation, cracking, void, and line integrity.

2) Measuring chip size, measuring line curvature, measuring the proportion of solder area of components.

3) Possible defects in PCB manufacturing processes, e.g.: misalignment, solder bridge and open.

4) SMT solder short, cold solder, component shifted, solder insufficient, solder void inspection and measurement.

5) Defect inspection of open, short or abnormal connections that may occur in automotive wiring harnesses and connectors.

6) Inner rupture or hollow inspection in plastic or metal.

7) Battery stacking uniformity, electrode welding inspection.

8) Seed, biological material inspection etc.

Application Field

LED, SMT, BGA, CSP, Flip Chip Inspection

Semiconductor, Packing components

Battery Industry

Electronic components, Auto parts, Photovoltaic Industry

Aluminum Die Casting, Moulding Plastic

Ceramics, Other special Industries

Related Article: x ray knowledge

Non-destructive testing DR X-Ray imaging

https://youtu.be/mSSlWIkEJqk

SPECIFICATIONS:

| Items | Contents |

|---|---|

| X-RAY launching tube Maximum tube voltage | Sealed type X-ray Tube |

| X-RAY launching tube Maximum tube voltage | 90kV (130kV Optional ) |

| X-RAY launching tube current | 10-300uA |

| Focal size | 5-8 μm |

| Detector Image Speed | 20 fps |

| Detector Resolution | 1536*1536 |

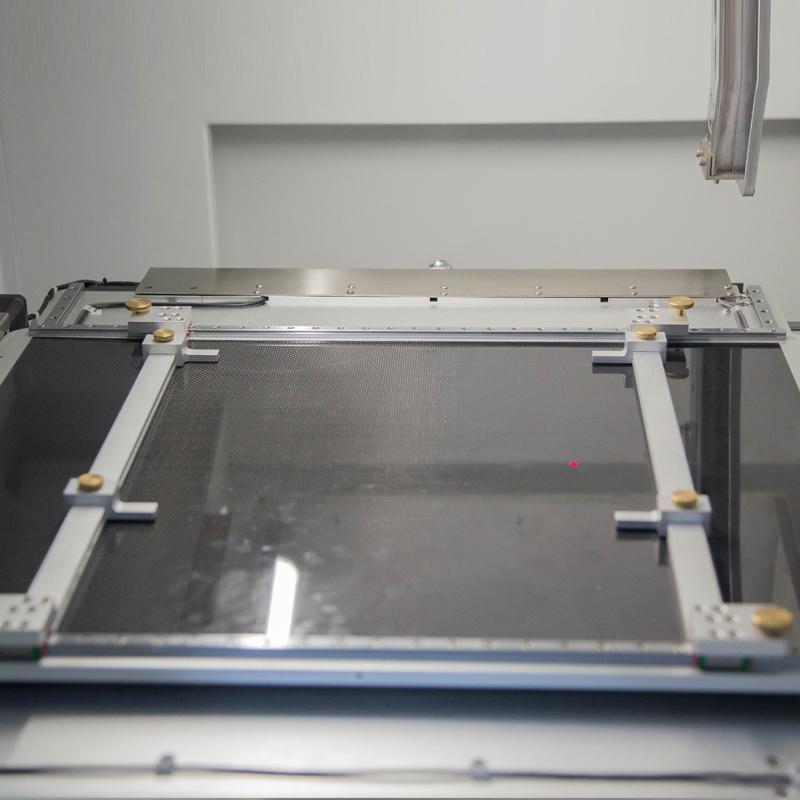

| Detector Tilt angle | Stage 360°rotation,Detector Tilting,Easily to detect the BGA soldering |

| Stage size | 500mm*500mm |

| Net weight | 1900 kg |

| Input voltage | AC 110-220V (+10%) |

| X-ray leakage amount | ≤1 u Sv/h |

| Operation System | Windows 7/Windows 10 |

| Total power | 1.5Kw |

| Flat Panel Detector | HD |

| LCD Monitor | 24 Inch |

| Dimension | L:1700mm, W :1770mm, H:1800mm |