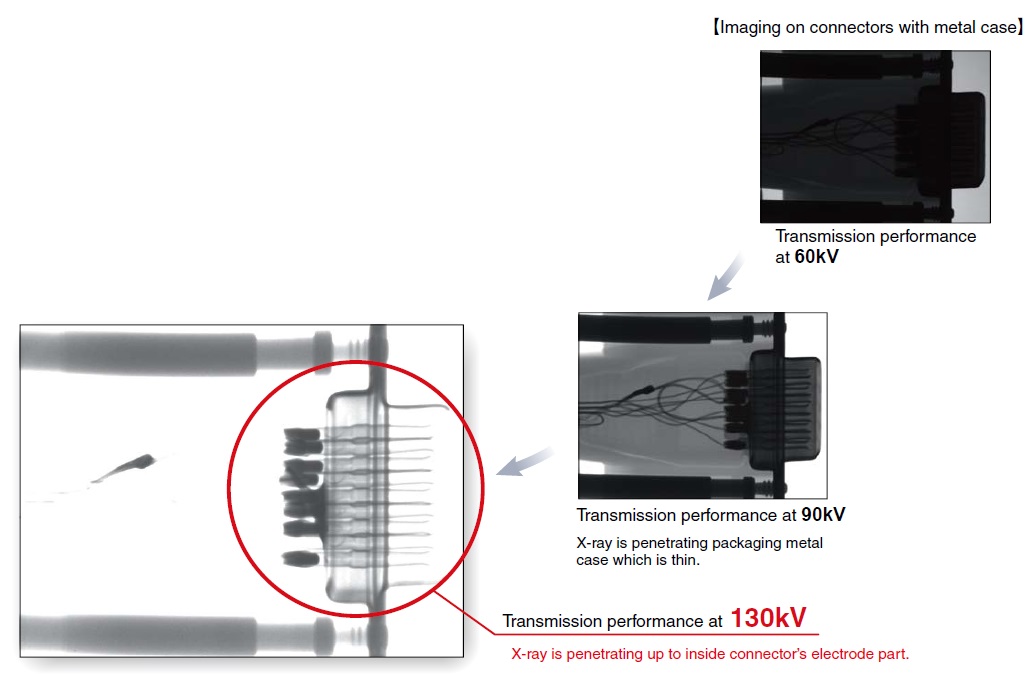

High transmission performance by 130kV micro focus X-ray source

Features

- Precise imaging of with heavy metals

- Easy setting and observing a single specimen at a micro or macro level

- Simple operation of batch inspections

- Various kinds of standard processing software

- CT Unit (option)

Models

| Model | X-ray generating unit | Imaging unit | Stage | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tube voltage | Output power | Focal spot size | Vertical stroke | Vertical Fieks size | Varid pixels | Density resolution | Monitor size | Vertical stroke | Sample stage | ||||||||||

| Small focal spot size | Large focal spot size | Small focal spot | Large focal spot | Size inch (mm) | X-Y stroke | Rotation stroke | Tilting stroke | ||||||||||||

| X-Y stage | Roatation stage | X-Y stage | Roatation stage | X-Y stage | Roatation stage | X-Y stage | Roatation stage | ||||||||||||

| µRay8400 | 40 to 130 (kV) | 8 W MAX (177 µA MAX) | 40W MAX (300 µA MAX) | 8 µm (5 µm@4 W) | 40 µm | 4.9-inch (125 mm) | 6-inch or 4-inch diagonal | 800,000 pixels | 10-bit | 21.5-inch | 13.8-inch (350 mm) | ||||||||

| 13.8 x 17.7 (350 x 450) | 5.9 x 5.9 (150 x 150)* | 13.8 x 13.8 (350 x 350) | 13.8 x 13.8 (350 x 350) | - | 360 degrees | - | +/-30 degrees (at CT option: +/-8 degrees) | ||||||||||||

* This size is standard. Installation of larger stage is also available.

Features

High Transmission performance Precise imaging even with heavy metals

130kV micro focus X-ray helps achieve excellent imaging with ease.

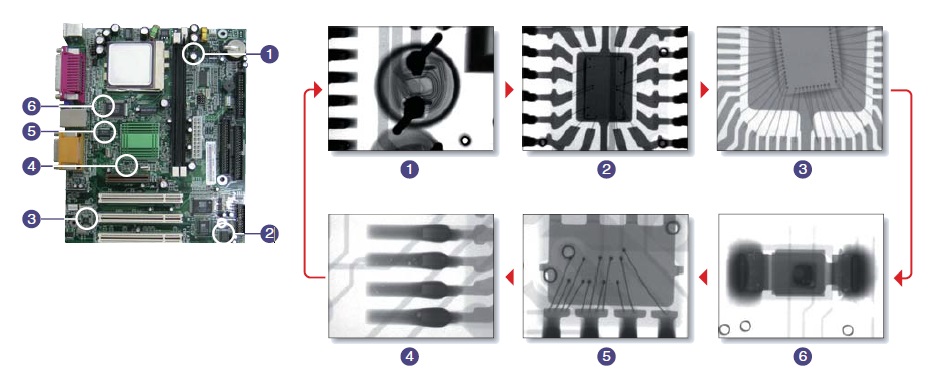

Capture clear image of sample covered by metal

This system equips 130 kV micro focus X-ray. It is most suitable for observing large footprint material or specimens that contain heavy metal. The minimum focal spot size is 5 μm, so even a magnified image is seen clear. Superior operability pursued with an XY stage that can be adjusted to desired position and angle with ease as well as original imaging software.

Easy setting and observation of specimen

Wide opening front door and spacious XY stage makes it easy to take out and set in specimens. There is additional side window that helps operator to observe the specimen inside the chamber, without approaching front window, whilst standing near to the PC monitor for operation convenience.

Functions

User-friendly operation.1No specialist knowledge or qualifications required.

Batch inspections are simple to perform.

The TEACHING functionmakes it easy to inspect predetermined points on multiple specimens with the same shape.

This function improves inspection efficiency by automatically moving the stage to pre-registered points.Once the positional data has been stored,you can display images of exactly the same points on multiple specimens with the same shape. Also, because settings such as the X-ray output rate, the magnification rate, and the stop time can be configured individually for each point, any type of specimen can be handled.

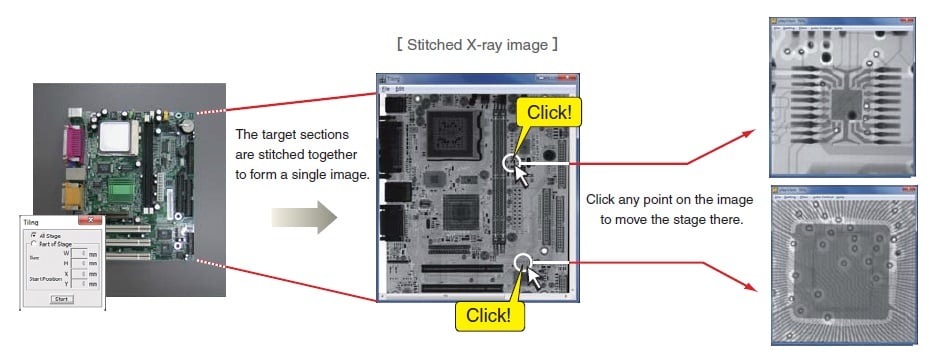

The STITCHING functionmakes it easy to observe a single specimen at a micro or macro level.

This function allows you to capture multiple X-ray images of areas of up to 13.8 x 13.8-inch (350 x 350xmm) for specimens that would be too large to capture in a single image. You can also capture an X-ray image of a particular section of a large specimen. In addition, once the images to be stitched together have been captured and saved, you can use the CLICK-TO CENTER function. To use this function, load the stitched image data and click the point you wish to view. The stage will automatically move to that point.

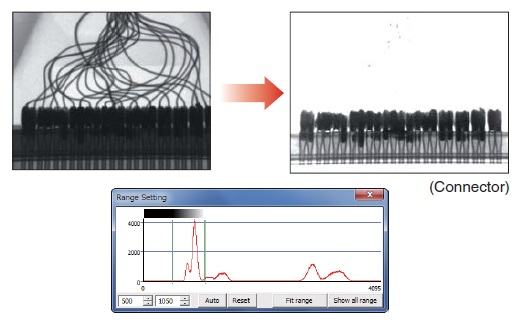

User-friendly operation.2The IMAGE PROCESSING function allows you to highlight part of an image to make it clear to anyone.

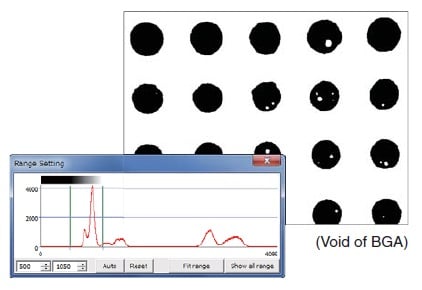

Display Range

Allows you to set an arbitrary gray level based on an image’s histogram and then enhance the contrast manually.

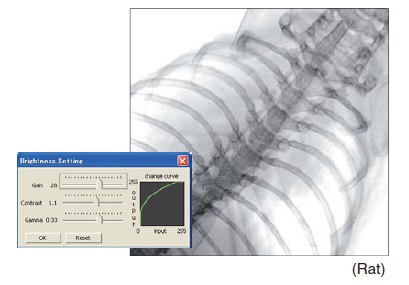

Brightness control

Individually controlling the gain, contrast, and gamma values allows for flexible change of the brightness value of images.

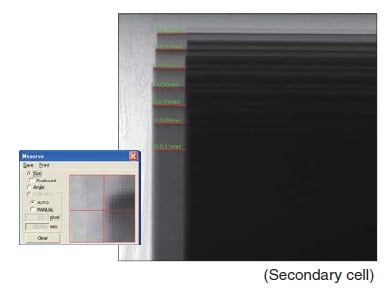

Size measurement

By drawing the measurement lines on the image, the dimensions within the image can be measured.

Threshold

Allows you to set all values above the threshold to white and all values below it to black.

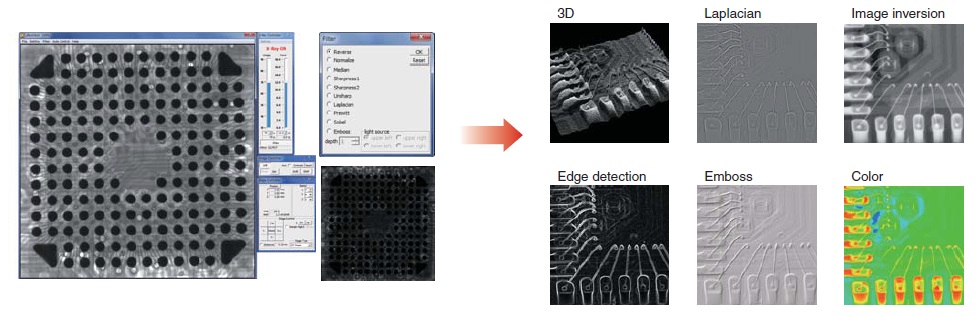

Filters

The μnRay series provides more than ten different types of filters and image processing functions that enable more detailed image analysis. Applying a filter to a moving image enables you to perform real-time image analysis.

Options

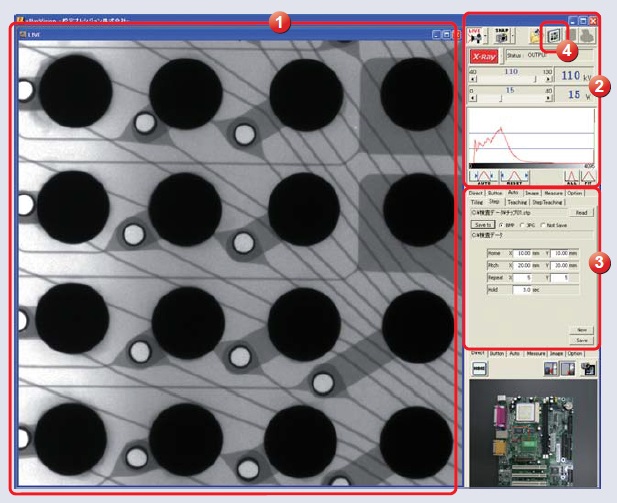

µRayVision.2 the system control software for capturing images

[Option: µRay8400 -LV2]

µRayVision2, the system control software for capturing images that has been designed exclusively for the µRay series—now employs a multiple document interface (MDI). By displaying multiple images in the same window, you can now compare images from the specimen you are inspecting with an image of a non-defective sample. You can also perform measurements on multiple images in order to evaluate them by comparison.

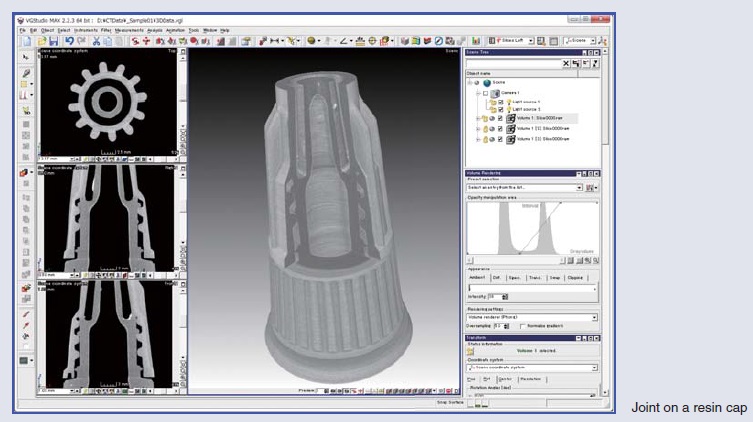

CT Unit 2D/ 3D analysis software

[Option:µRay8400 -LCTN, -LCTM, -LCTX]

A fluoroscope can only capture projection images, but a CT Unit can capture 3D images. A CT Unit can also capture tomographic images of the specified surface of a 3D image.

Wide view X-ray I·I camera

[Option: µRay8400-L4/2,-L3]

This option provides wide view camera that enables to capture wider surface of a sample, suitable for case wider view is preferred rather than higher magnification.

Mega-pixel high resolution digital FPD

[Option: µRay8400 -LF]

Applications

Field and Application Example

- Pharmaceuticals and Cosmetics

- tablet, capsule, catheter, medical pouch, foreign object detecting in the mask, cosmetic

- Automobiles with Electric Vehicles

- automotive component, harness, battery, resin molded part, motor, insert molded part, aluminum die cast part, sensor, fitting of part

- Electrics and Electronics

- BGA, IC, connector, capacitor, LED, relay, electronic circuit board (PCB), AC adapter, lamp filament, cable disconnection, electric discharge trace after insulation breakdown

- Advanced Materials

- CERP, insulation material, carbon, junction of different materials, foreign material inspection of beryllium

- Precision Instruments

- probe, bearing, fitting of resin container, inspection to insertion position of spring

- Creatures and Plants

- rat for research, seed, flower, shell, bone, insect, rice

- Others

- microscopic foreign object mixing, cavity on the wielding part, inspection of plastic bottle, sealing of can