The Vibratory Polishing Machine Qpol Vibro (SAPHIR VIBRO) is designed for the preparation of specimen surfaces practically without deformation. This preparation method is especially suited for further characterizations like EBSD (electron backscatter diffraction), nano indentation using AFM (atomic force microscopy) or micro hardness testing.

Due to the very gentle removal of material it is applicable especially for soft and ductile materials, like titanium-aluminum, pure copper and copper alloys, aluminum alloys, soft steel, and nickel-based alloys.

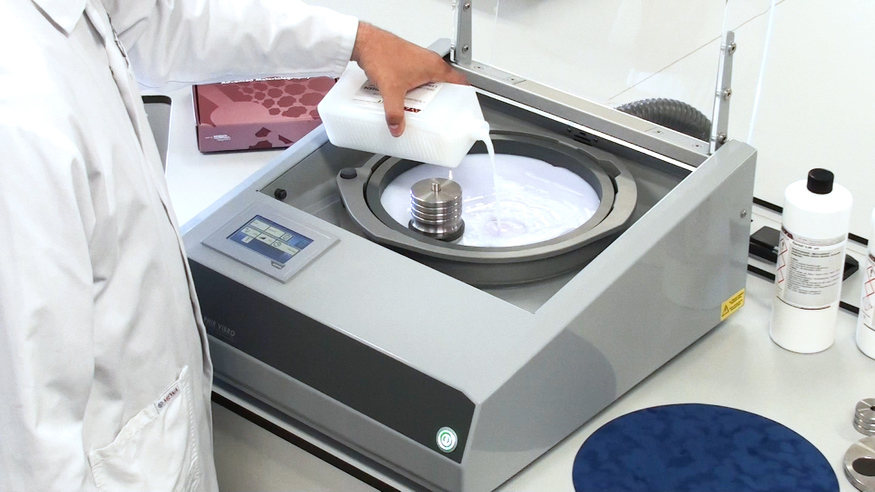

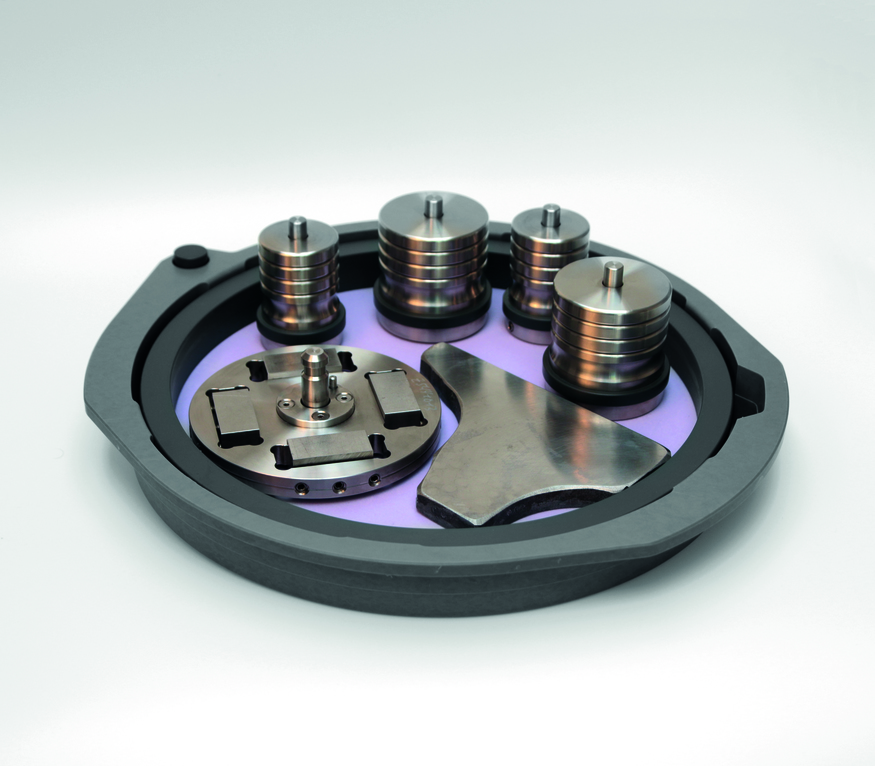

Having a diameter of Ø=308mm, the large bowl provides sufficient space for polishing of a complete sample holder, large specimens or for the simultaneous polishing of up to 21 mounted specimens. The bowl is equipped with a double magnetic system. It allows to fix, remove and clean both the bowl or polishing cloth very quickly, without any tools or other fixings. Polishing cloths suited for magnetic system with a diameter of 300mm or 305mm (12”) can be used.

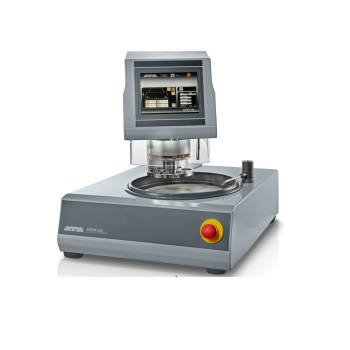

The user interface is very intuitive and offers a lot of features supporting the operator.

- Depending on the mass of the inserted specimens the automatic frequency control selects the optimal vibrational frequency in the range from 60 to 120Hz. Manual adjustment is therefore not necessary.

- As almost indefinite polishing time can be chosen, the Saphir Vibro is equipped with the QATM Surface-Guard. It suppresses crystallization or corrosion of the polished surface in the absence of the operator after a preparation recipe has ended.

- Pre-installed preparation methods and consumables can be selected for various materials

- A pre-installed list of consumables can be edited and extended by the customer

- Up to 200 preparation methods can be saved

For achieving best working conditions the Saphir vibro is equipped with an exhaust connection plug, which can be connected to an external exhaust air system. Based on the vibration adsorbing construction the Saphir Vibro provides a low noise operation.

PRODUCT ADVANTAGES

- Rapid changeable polishing bowl with magnetic system

- Surface-Guard: reduces crystallization and corrosion of the specimen surface

- Automatic frequency control from 60-120 Hz, e.g. for mass variation

- Intuitive user interface and touch screen

- Pre-installed preparation methods and consumable list

- Low-noise operation, almost indefinite polishing time without supervision

- Exhaust connection plug (exhaust connection for enhanced user-friendliness and safety)

- Up to 200 custom preparation methods can be saved

FEATURES

| Polishing bowl | Ø 308 mm (compatible with 300 mm or 305 mm (12") polishing cloths) |

| Vibration frequency | 60 - 120 Hz |

| Plugs | USB, Ethernet |

| Connection power | 0.25 kVA |

| Drive power | 135 VA |

| W x H x D | 510 x 300 x 590 mm |

| Weight | ~ 45 kg |