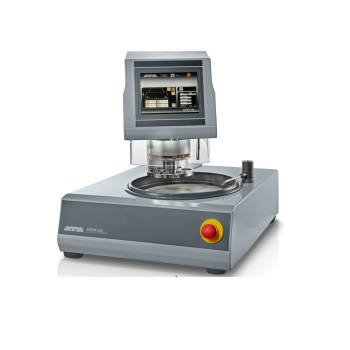

The new holder for the working wheel (single-disc design) enables operation without carrier disc without compromising performance. The control software allows to edit and save up to 200 preparation methods, protected by a user account management.

Pressure, speed and direction of rotation (head and working disc) are adjustable. A spin cycle function (Cleaning Boost) helps to spin dry the grinding and polishing medium at 750 rpm at the end of the preparation process within 3 seconds.

The robust machine can be combined with the dosing system TOPAS ECO and offers maximum flexibility for sample preparation and operating convenience.

PRODUCT ADVANTAGES

- Single wheel grinder/polisher

- Spin cycle function (Cleaning Boost)

- 4.3" Touch-Screen with intuitive QATM user software

- 200 customized programs storable

- Easy cleaning/rinsing of bowl by lifting the working wheel (single-disc design)

- Variable speed of working wheel and polishing head

- Working wheel and polishing head: clockwise / counter-clockwise rotation

- Impact-proof plastic bowl

- Aluminium case, powder-coated

- Economic LED illumination

FEATURES

| Working wheels | Ø 200/250 mm |

| No. of samples (single pressure) | 1-5 samples Ø 40 mm |

| Single pressing force | variable, 5-80 N |

| Central pressing force | variable, 20-285 N (expert mode: 20-350 N) |

| Connection power | 2.3 kVA |

| Drive power (grinder) | 0.55 kW (S1) |

| Drive power (head) | 0.18 kW (S1) |

| Speed (grinder) | 30 - 600 min-1 |

| Speed (head) | 30 - 160 min-1 |

| W x H x D | 511 x 530-610 x 710 mm |

| Weight | ~ 64 - 72 kg |

| Water connection | 1x fresh water connection R½" max. 6 bars |

| Dosing system (option) | Topas ECO |

Qdoser ECO (TOPAS ECO)

The fully automatic dosing system Qdoser ECO is suitable for use with the automatic grinders of the Qpol 250 A series. Four 500 ml glass bottles with screw caps hold 3 x suspension and 1 x lubricant or 4 x Dia-Complete and can be filled via a separate lid. They are easily removed for cleaning.

The dosing nozzles are inserted into a holder attached to the head. The dosing interval is controlled via the touch screen and the software of the SAPHIR 250 A devices. The backflushing function keeps the hoses clean.

- Automatic dosing unit for

3x diamond suspension and 1x lubricant or

4x Dia-Complete - Dosing interval adjustable

- Reverse rinsing function

- Controlled by the control software of the Qpol 250 A grinders/polishers

- For all Qpol 250 A grinders/polishers

- Suspension containers refi llable and removable

- incl. dosing nozzles (inserted into a holder attached to the head)