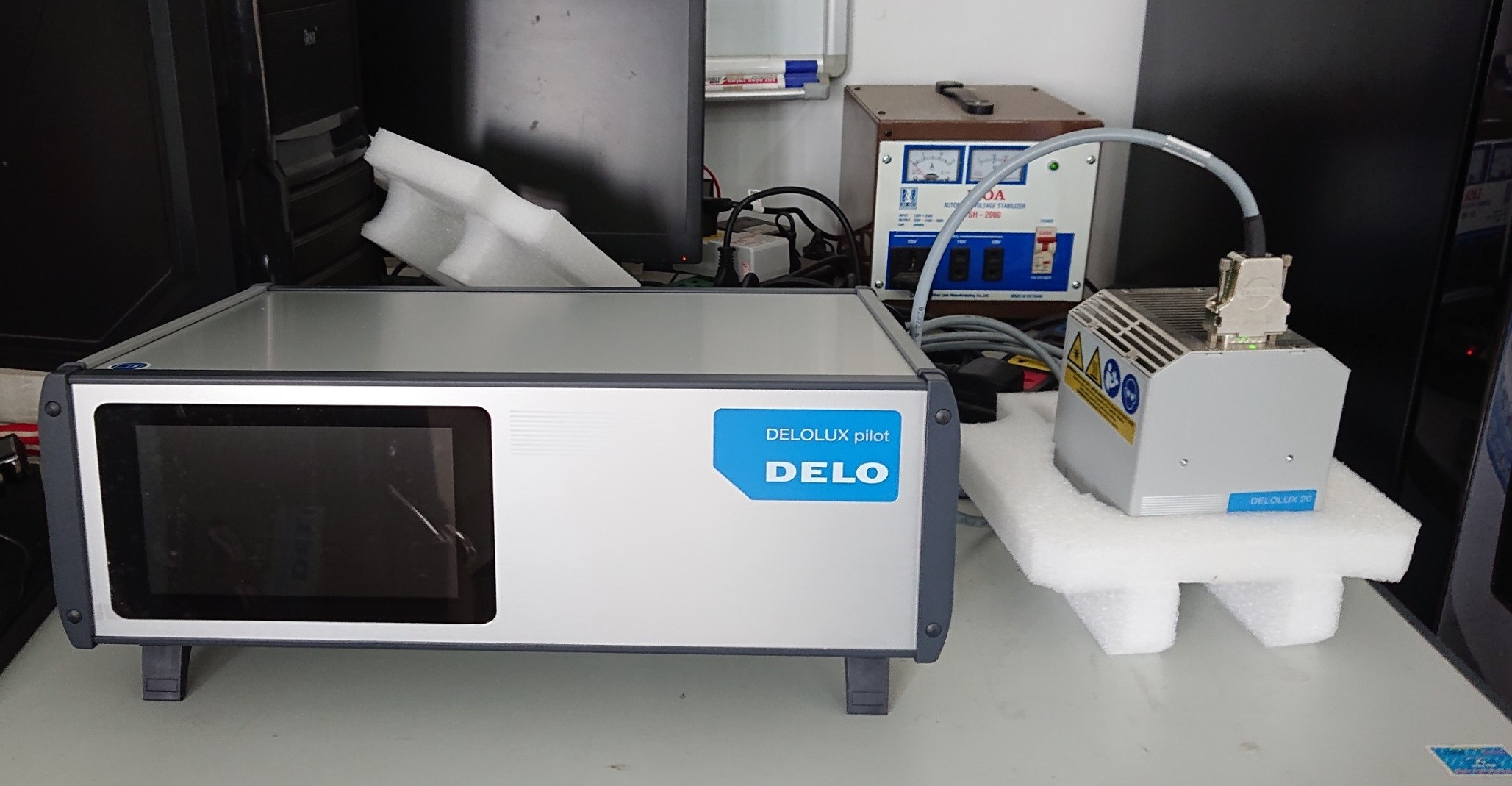

DELOLUX pilot AxT controller for UV lamp DELOLUX 20/202 cure glue on a large area

DELOLUX pilot A1T

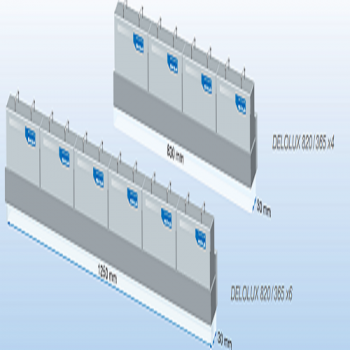

DELOLUX pilot AxT has a compact module form, connecting up to 4 lamp heads, for stability and long life (> 20000 h), ensuring safe operation when working with DELOLUX 20/202.

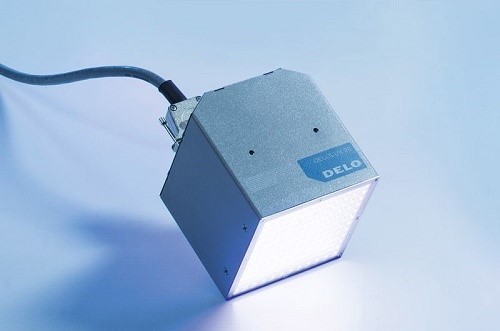

The DELOLUX 20 / 202 UV lamp is suitable for UV glue curing applications over a large area (from 100~400 mm2). With an intensity of up to 2,000 mW/cm², this UV lamp can give an exposure time of just a few seconds. Moreover, this device is not only space-efficient but also extremely reliable: Uniform light intensity.

Each lamp head can be controlled independently of the other. Users can customize the installation according to their needs.

|  |

DELOLUX 20 | DELOLUX 202 |

DELOLUX 20/202 lamp head types

DELOLUX pilot AxT also allows users to connect to the PLC controller via the integrated connector on the back of the machine, allowing fully automatic control according to the user's desired programming. This is extremely convenient for the installation of fully automatic lines.

Back view of DELOLUX pilot A1T controller

Application:

Glue drying for applications such as:

- Glue the screen of TV, phone, tablet, ...

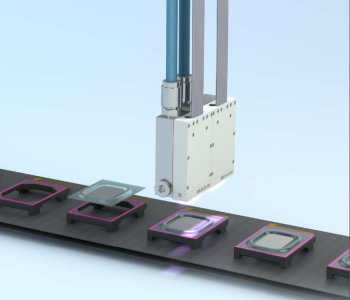

- Glue curing on conveyor belts, fully automated, for microchips, chips, etc.

- Activation drying for DELO's PHOTOBOND, KATIOBOND glue lines, ...

- Curing large parts such as for electric motors, bearings, magnets to housing bonding, ...

Specifications DELOLUX pilot AxT:

Model | DELOLUX pilot AxT |

Dimensions (WxDxH mm) | 440 mm x 305 mm x 153 mm |

Working temperature range | +15 °C to +45 °C |

Power Consumption | A1T: 515W A2T: 825 W A3T: 1,140 W A4T: 1,450 watts |

Parameter setting | Intensity: 15%~100% capacity (minimum division: 0.1%) Irradiation time: 0.1s ~ ∞ s |

Installation location | Put on the desk, move easily Available on amount thanks to the 19-inch retaining bracket (optional) |

Usage screen | 7-inch touch screen, |

Weight | A1T: 5.7 kg A2T: 7.9 kg A3T: 10.1 kg A4T: 12.3 kg |

Compatible Lamp Heads | DELOLUX 20 DELOLUX 202 |

For more detailed advice on this product line, interested customers, please contact HUST Vietnam.

HUST Vietnam is proud to be the exclusive distributor of DELO adhesive products and technology transfer from DELO in Vietnam!