LED small-area lamps for maximum flexibility in adhesive curing

DELOLUX 30 impresses with a peak intensity of over 25,000 W/cm² and homogeneous intensity distribution.

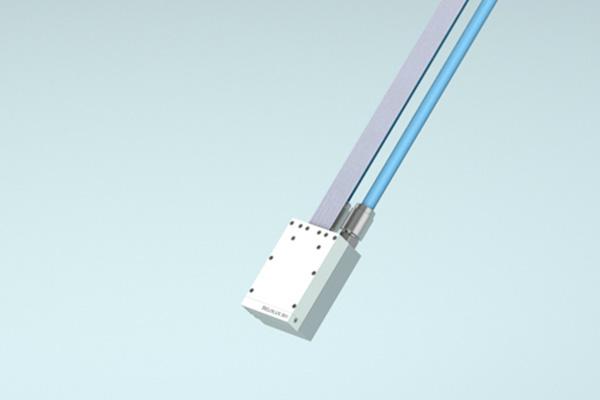

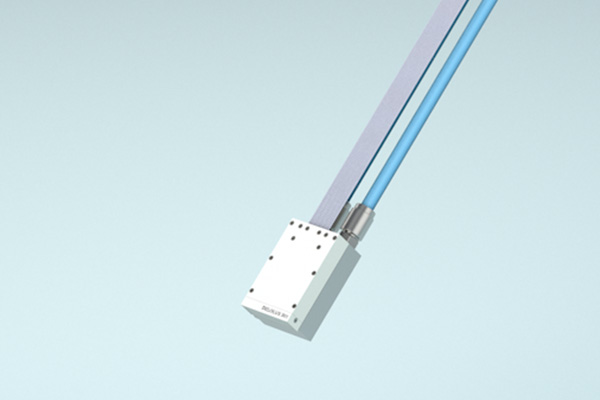

The new small-area lamp is available in wavelengths of 365, 400 and 460 nm and comes in two versions: an all-in-one version with integrated water cooling and control unit and a single lamp head.

The DELOLUX 30 all-in-one system includes a permanently installed DELOLUX pilot A1T control module with integrated water cooling and a specially developed, closed and monitored Coldguide® liquid circuit in the lamp head. This means that you do not need any additional connections for the water-cooling system, enabling plug & play operation.

The LED head can be flexibly adapted to your individual requirements and seamlessly integrated into your production line. It includes a permanently installed connection for your external water-cooling system and is operated with the DELOLUX pilot A-Series devices.

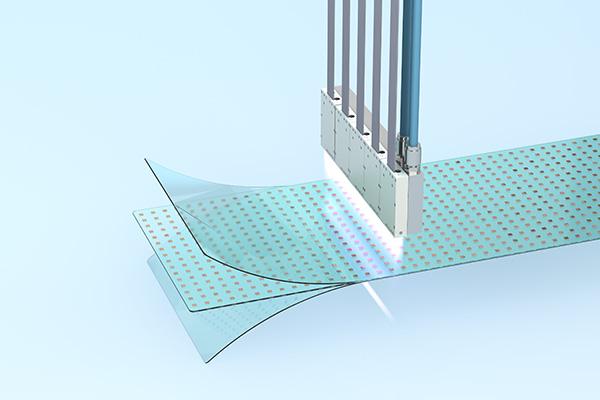

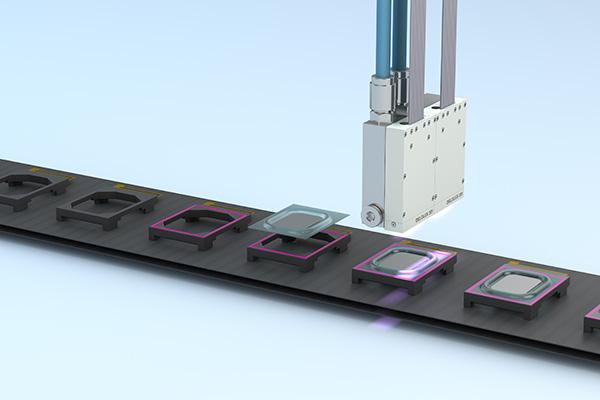

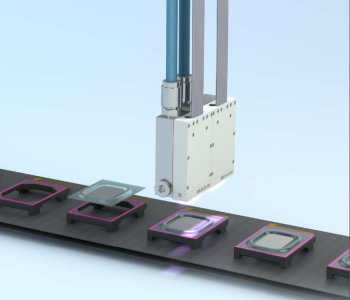

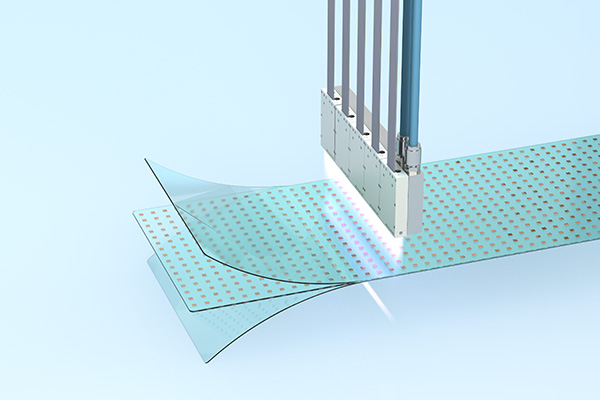

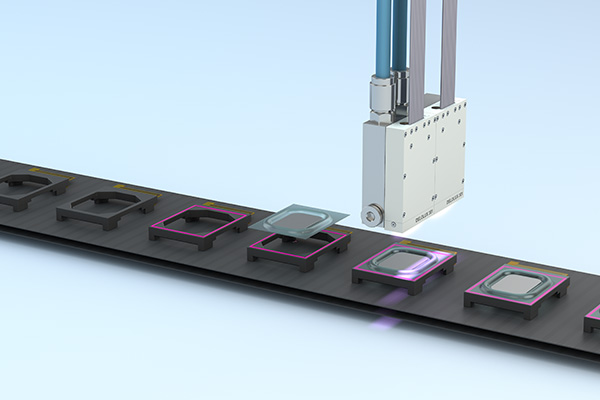

The DELOLUX 30 can be used for a wide range of applications: In LED packaging, it enables shorter exposure times thanks to higher peak intensity. In the automotive industry, it optimizes chip encapsulation processes through mere seconds of exposure, resulting in reduced cycle and throughput times.

|  |  |

|  |

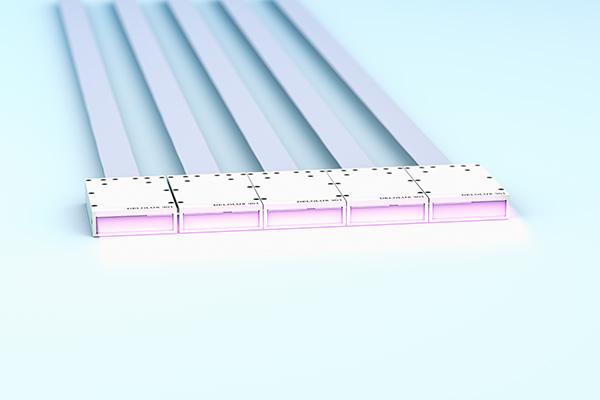

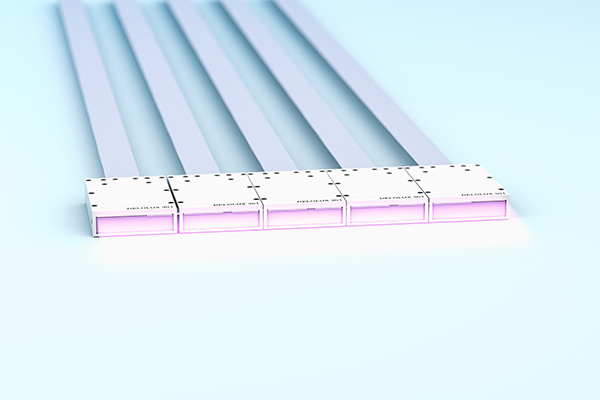

DELOLUX 301 is particularly suitable for near-fully automated processes in small and narrow production lines. The lamp offers the highest possible curing speeds and exceptional flexibility for production systems integration. It is available in the wavelengths 365 nm, 400 nm and optionally 460 nm. Depending on the process, it can be used passively or water-cooled.

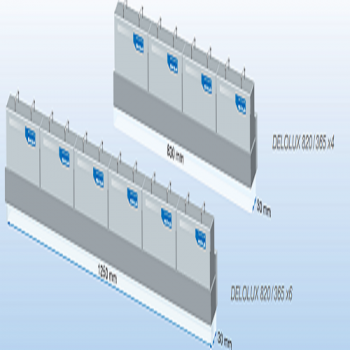

The lamp head produces a linear exposure area of 38.7 mm x 8.45 mm. DELOLUX 301 can be operated as a single head or linked to form a larger array. As the lamp heads can be arranged seamlessly in at least three directions, individual and at the same time homogeneous lighting surfaces can be created.

Advantages at a glance:

- Fast fixation due to maximum intensity

- Short cycle times and increased production efficiency

- Flexibility in the process thanks to the largest possible working distances

- Flexibility thanks to DELOLUX 30 all-in-one version and LED head

- Achievable service life > 20,000 hours

- Advice and customized solutions from a single source: high-tech adhesives, dosing systems and curing lamps

Brochures of DELOLUX 30 | 301