How to choose controller model for DELOLUX 20/202 UV lamps

17:47 - 20/05/2021

DELOLUX 20/202 lamp heads are used to irradiate UV glue when applied to large surface areas such as car screens, phones, electric motors, bearings, and magnets to housing bonding, ...(with the usual area from 100 ~ 400 cm 2, can be increased or decreased depending on customer requirements).

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

DELOLUX lamps of DELO (Germany) are a variety of types and pairing methods, so it makes users have trouble choosing the right configuration for their application.

This article will summarize the detailed configuration of a set of DELO: DELOLUX 20/202 UV glue curing lamps, helping you to have a better overview of the UV glue drying lamps.

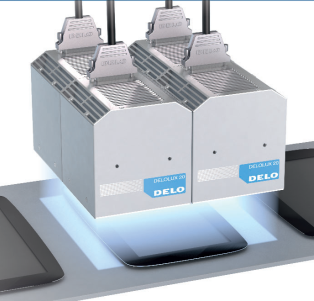

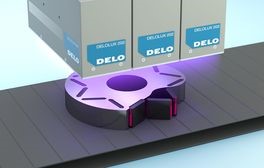

DELOLUX 20/202 lamp heads are used to irradiate UV glue when applied to large surface areas such as car screens, phones, electric motors, bearings, magnets to housing bonding, ...(with the usual area from 100 ~ 400 cm2, which can be increased or decreased depending on customer requirements).

|  |

DELOLUX 20 | DELOLUX 202 |

Example of UV adhesive curing application with DELOLUX 20/202 lamp

Overview of the types of lamp heads DELOLUX 20/202:

Specifications | DELOLUX 20 | DELOLUX 202 |

Illustrations |  |  |

Dimensions (WxDXH mm) | 112 x 112 x 112 mm | 209 x 67 x 121 mm |

Irradiation area | 100 x 100 mm | 202 x 49 mm |

Wavelength (nm) | 365, 400 nm | 365, 400 nm |

Intensity (mW/cm 2) | 365 / A1: 600 365 / A2: 1200 400 / A1: 1000 400 / A2: 2000 | 365 / A1: 600 365 / A2: 1200 400 / A1: 1000 400 / A2: 2000 |

Weight | 1.65 kg | 2.05 kg |

Power source | From DELO pilot Axi / AxT | |

These lamp heads are controlled by the DELOLUX pilot Axi or AxT. These are two new models that are improved by DELO, with higher irradiation capacity and easier-to-install design.

Normally, for DELO's UV glue lines, only irradiation with an intensity of 200 mW/cm 2 (maximum 700 mW/cm 2 just for some special adhesives) is needed, so the distance to the sample can be customized quite comfortably, mainly attention should be paid to the irradiation area so that the UV light covers the entire dispensing area.

| |  | |

| AxT Controller | Axis Controller | |

| DELOLUX pilot Axi (i=integrated, x =1,2,3,4, is the number of lamps that can be attached) is used for DELOLUX 20 / 202 lamps and is specialized for integration with PLC systems, controlling for that automatic production line. | DELOLUX pilot AxT (T=touch) is a model that integrates both manual control modes by touch screen or can also be connected to the PLC system for automatic control. |

AxT/Axi Controller Specifications:

Specifications | DELOLUX pilot AxT | DELOLUX pilot Axi |

Maximum number of connected lights | 4 | 2 |

Dimensions (WxDXH mm) | 444 x 305 x 151 mm | A1i: 305 x 184 x 146 mm A2i: 305 x 250 x 146 mm |

Weight | A1T: 5.7 kg | A1i: 4.8 kg |

A2T: 7.9 kg | A2i: 7.04 kg | |

A3T: 10.1 kg |

| |

A4T: 12.3 kg | ||

Intensity deviation | ±2% max. | ±2% max. |

Power Consumption | Maximum: 1.45 kW | A1i: 550W A2i: 900W |

Power source | 220 V AC, 1 pha, 50 - 60 Hz. | |

To pair the DELOLUX 20/202 lamp with the AxT/Axi controller:

- These DELOLUX 20/202 lamps can all be connected from 1~4 to run at the same time on the AxT pilot controller or 1~2 on the Axi pilot.

- We are interested in the number of sockets x of the respective AxT/Axi controllers.

(x =1~4 is the number of sockets); - There are 2 types of lamp heads, A1 and A2;

- A1 requires 1 socket;

- A2 needs 02 sockets;

Thus, we have the following pairing options:

DELOLUX pilot AxT | DELOLUX 20/202 (A1, A2) |

A1T | 01 A1 |

A2T | 02 A1 or 01 A2 |

A3T | 03 A1 or 01 A2 + 01 A1 |

A4t | 04 A1 or 02 A2 or 01 A2 + 02 A1 |

| |

A1i | 01 A1 |

A2i | 02 A1 or 01 A2 |

By using the DELOLUXcontrol irradiance meter, it is easy to control the UV intensity and align the irradiation distance to the sample as well as the power set on the DELOLUX Axi/AxT controller.

DELOLUXcontrol UV irradiation intensity meter

Thus, depending on the needs and purposes of use, you can easily choose for yourself the most suitable configuration for your glue drying application.

Hope this article brings a lot of useful information for readers and customers!

For more product advice and answers to questions, please feel free to contact us!

HUST Vietnam exclusively distributes adhesive products and solutions for dispensing, and curing of DELO in Vietnam.