Introducing DELOLUX 301

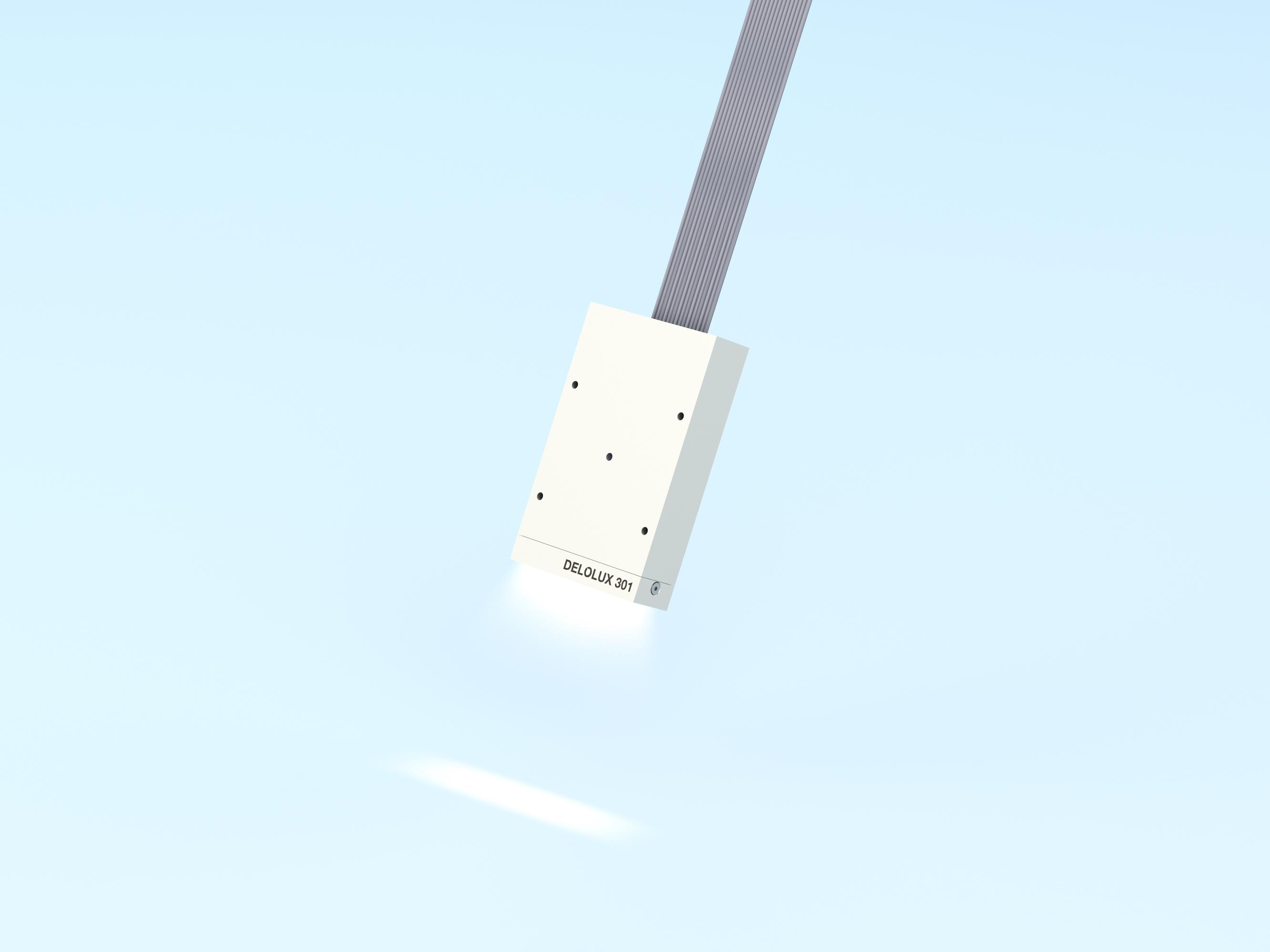

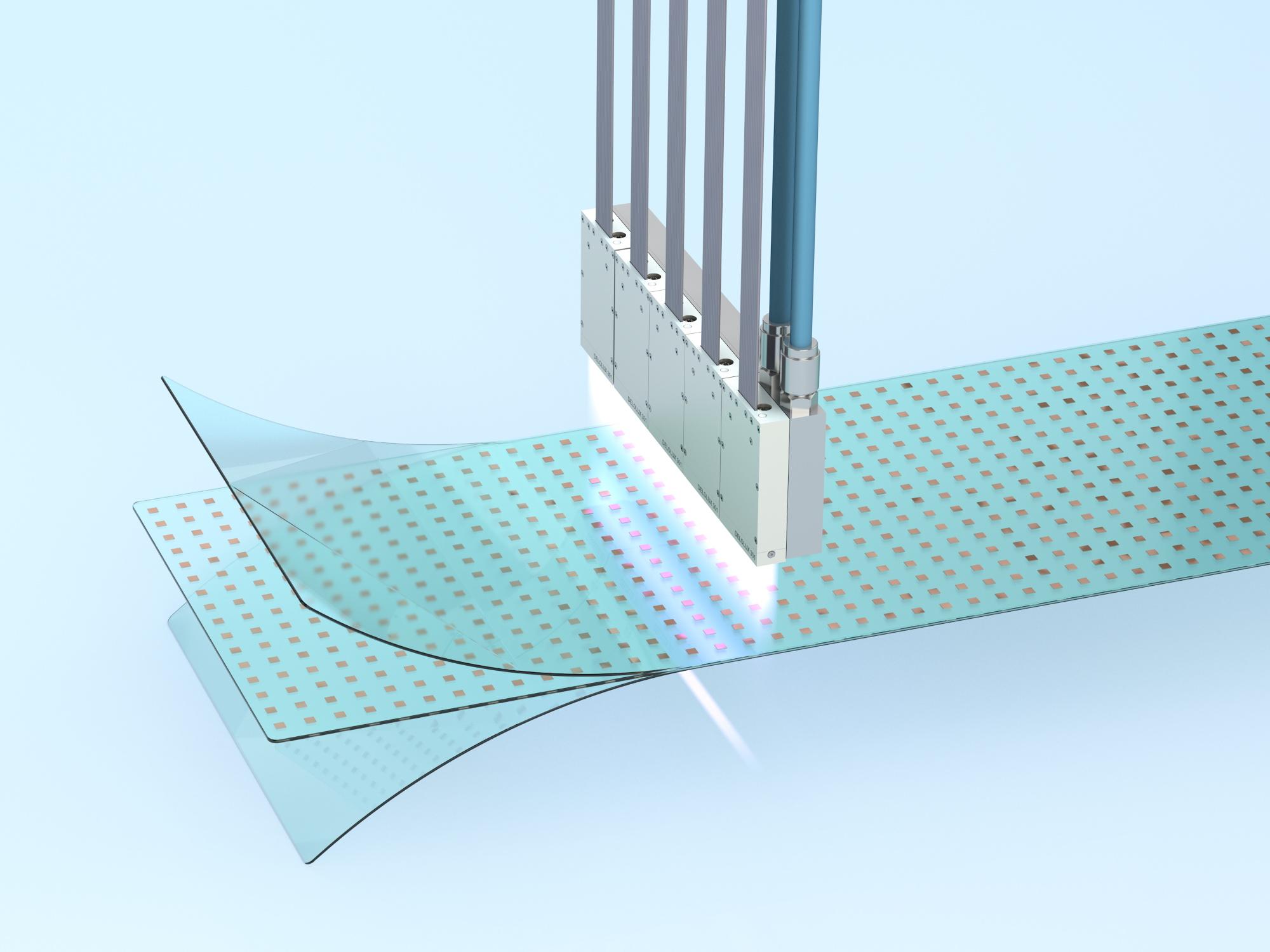

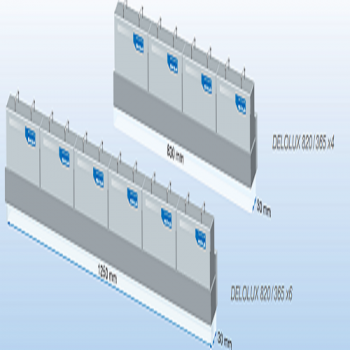

- DELOLUX 301 with compact size, highest irradiation intensity in the entire DELOLUX family. It can be used as a single head or pieced together into a large area array.

- The lamp head operates with an externally exposed water cooler, which can be individually developed according to customer requirements.

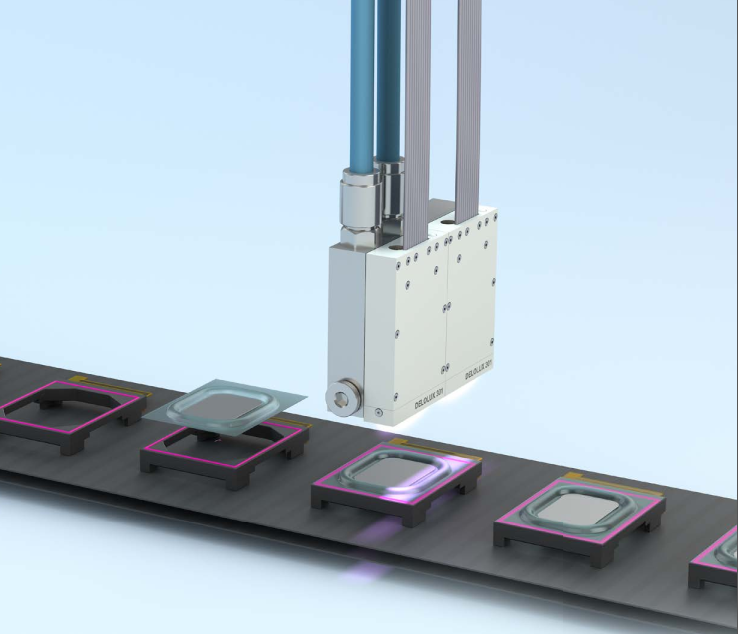

- DELOLUX 301 offers fast curing speed and great flexibility for integration into production systems. This lamp is suitable for highly automated processes in small and narrow production lines, such as consumer electronics assembly lines.

- In addition, the DELOLUX 301 has a lifespan of > 20,000 hours (~2.5 years of continuous operation), allowing continuous operation while ensuring a long life.

Application:

- Suitable for all DELO UV glues such as PHOTOBOND, KATIOBOND, DUALBOND, etc.

- Mounting glass, glass;

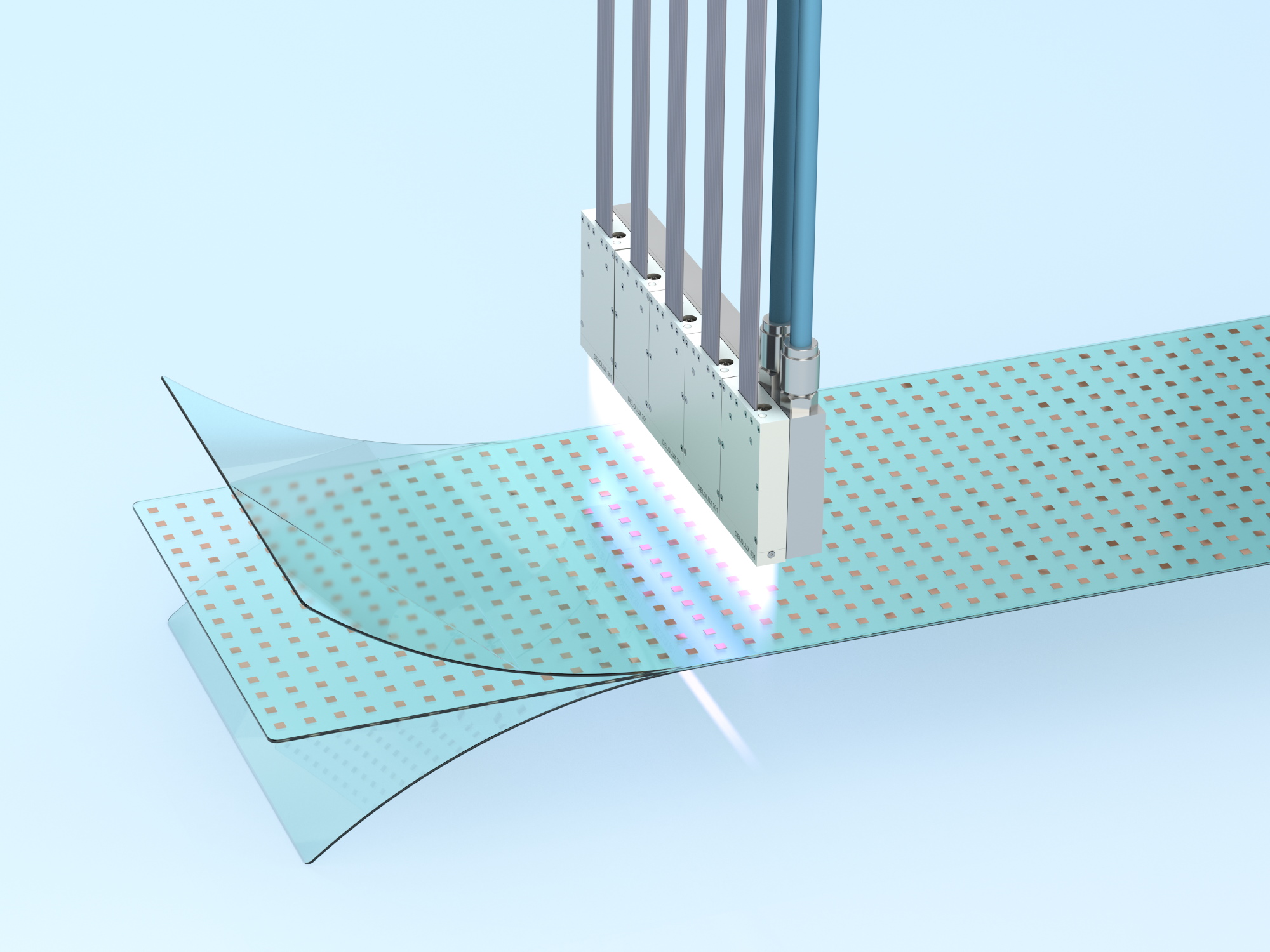

- Apply glue on the surface of the product;

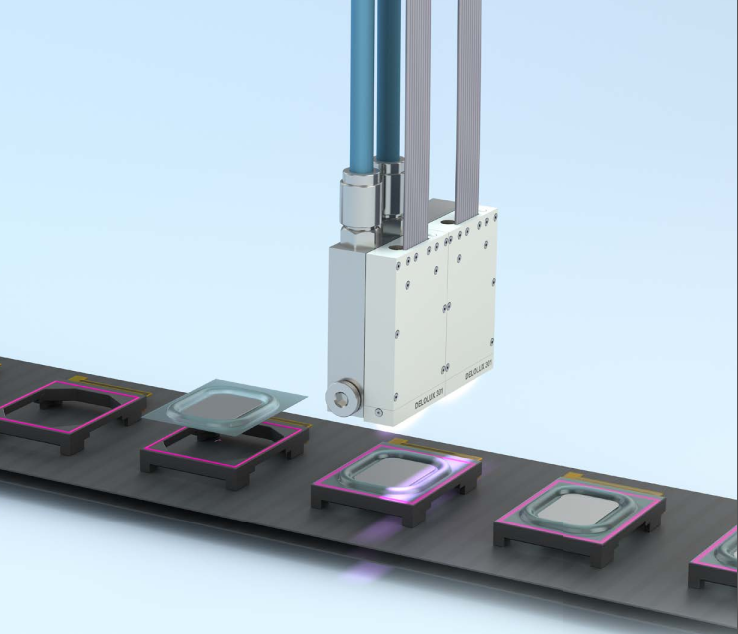

- Attach details and components with small size;

- Microswitch Microswitch;

- Mount speaker phone, tablet…

|  |

| Application of UV glue curing for electronic components production line (Photo DELO) | |

Specifications of DELOLUX 301 UV Lamp Set:

Parameter | DELOLUX 301 |

Dimensions (Width x Depth x Height): | 42.7 mm × 13 mm × 67.2 mm |

Irradiation area: | 38.7 mm × 8.45 mm |

Irradiation intensity: | 365 nm: ≥ 13.500 mW/cm² @ 2 mm |

400 nm: ≥ 22.500 mW/cm² @ 2 mm | |

Cooling: | Water-cooled, externally integrated |

Operating temperature: | 15 °C to 45 °C |

Weight: | 280 g |

Lamp head power consumption: | 340W |

Cooler capacity: | 220W |

Power of AxT controller: | 515W ~ 1450W (from A1T to A4T) |

The focal length of the connecting wire: | 3m (other sizes can be optional) |

Control | DELOLUX pilot or optional by PLC |

Power supply for the controller | 220V, 50 Hz, 1 phase, IEC line 16A |

The full set includes:

STT | Device name | Reference images |

1 | DELOLUX 301 lamp head | |

2 | Heatsink connector |  |

3 | DELOLUX pilot controller AxT / Axi |  |

4 | Flat Cables |  |

5 | DELOLUXcontrol UV Intensity Meter (Optional) |  |

6 | UV intensity sensor head (Optional) |  |

7 | UV protection glasses (Optional) |  |

Contact HUST Vietnam for detailed advice and choose the most suitable configuration for your application!