Introduce:

- Two-component adhesive, room-temperature curing, high-viscosity, base on polyurethane adhesive allowing for use in a wide range of applications;

- Resistant to media and corrosive substances;

- Compliance RoHS standard 2015/863/EU;

- Passed the ANSI/UL 94 HB flame retardant test.

|  |

| Glue can be packaged in a ready-to-use Automix dual cartridge for use with the DELO Xpress 902 glue gun or in large bottles for industrial production. | |

Application:

- DELO-PUR9694 is multi-purpose, bonding glass/metal, PBT, PET, and many other materials.

- Fix components with passivation surfaces (Ferrite, PBT, Al, PET foil), such as coils, capacitors, and plugs, etc. on the FR4 printed circuit board to prevent vibration;

- The glue has a good resilience to the touch, high strength for both static and dynamic loads, good response to large gaps due to its ability to resist vibration during operation.

- Typically, after cured, adhesives can use in a temperature range of -40 oC ~ +125 oC, depending on the application.

Some typical applications of PUR9694 glue:

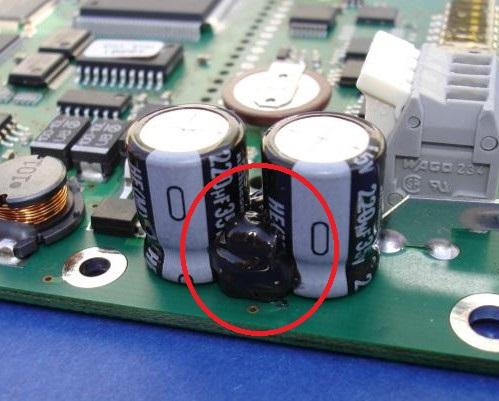

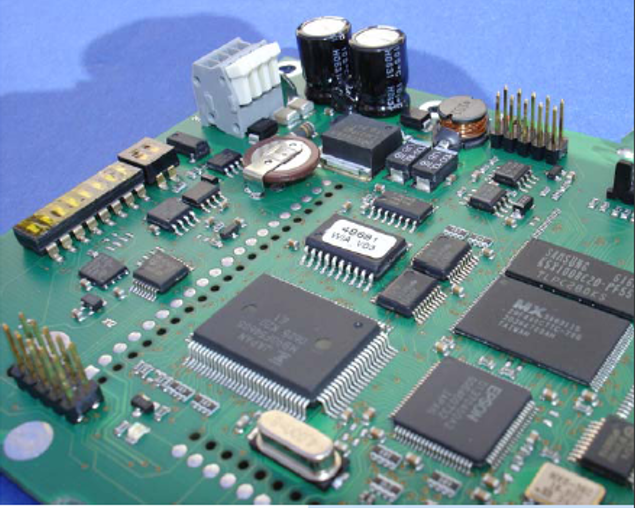

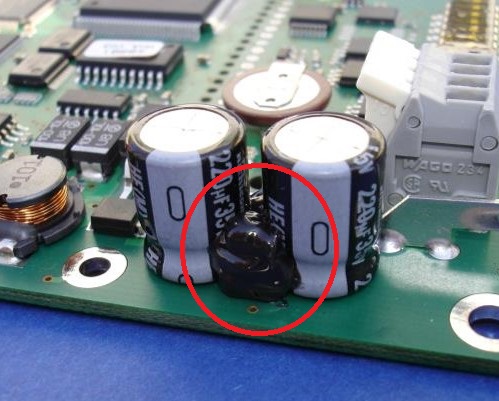

1. Fix components on printed circuit boards as protection against vibration

|  |

| Fix passive components, such as coils, capacitors, and plugs, on printed circuit boards to prevent vibration (Photo DELO) | |

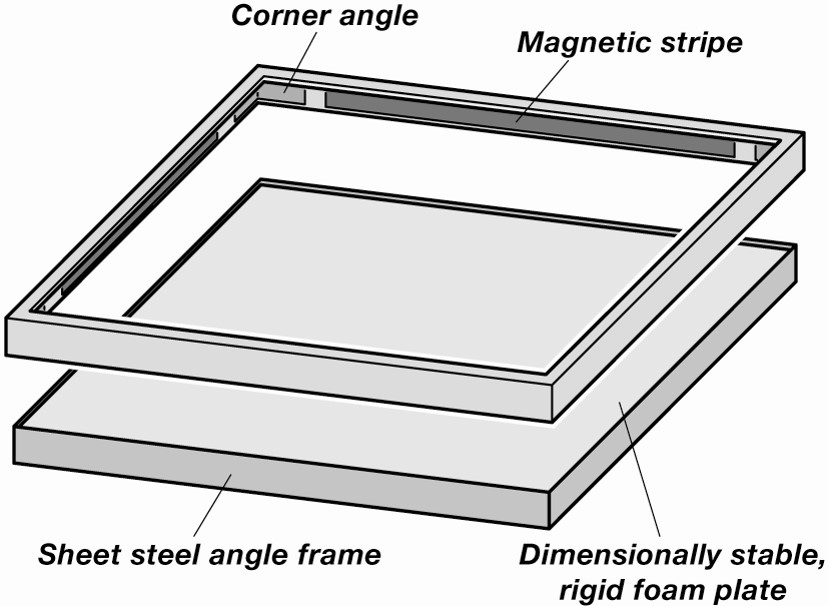

2. Adhesive wooden frame ( Wooden Frame)

|  |

| Bond metal corners to wooden frames as corner joints (DELO Photo) | |

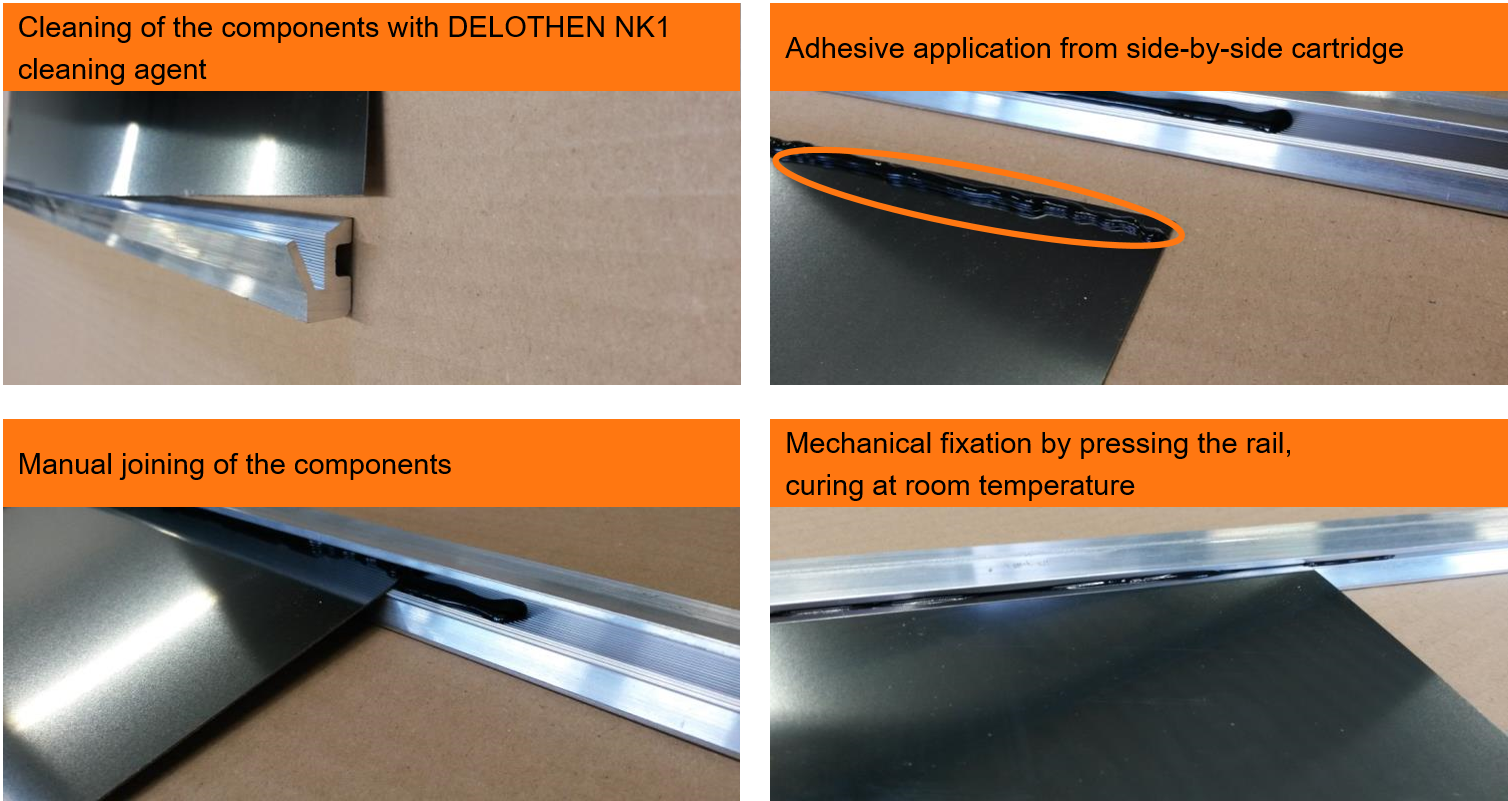

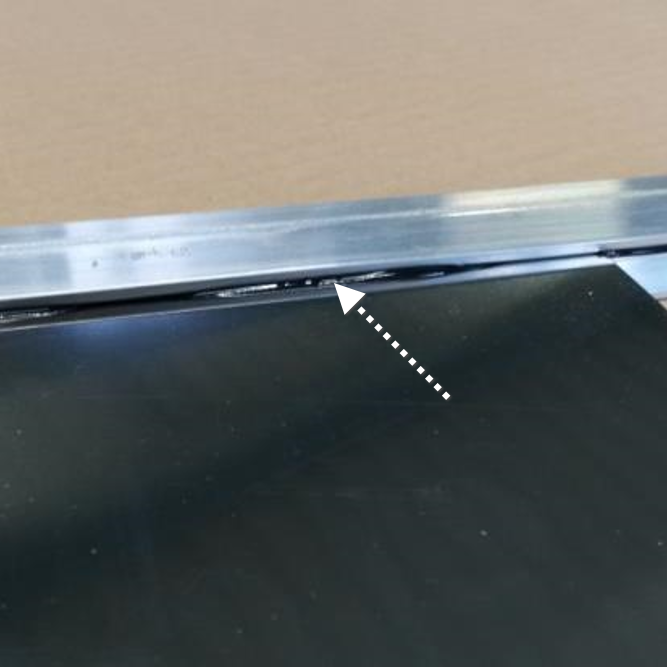

3. Tension Rails of a Printing Machine

|  |

| Bond the tensile rails to a printer (DELO Photo) | |

Curing process:

- The glue dries quickly at room temperature (23 0C).

- Heat curing for the glue will help the glue dry faster, but it may cause a change in the physical properties of the glue.

| Curing time |

Temperature | |

23 0 C | 800C | |

Tensile shear strength 1~2 MPa | 2h | 5 minutes |

Time for the glue to reach the required tensile force (tensile shear strength >10 MPa) | 8h | 30 minutes |

Time for the glue to reach the final force | 72h | 40 minutes |

Specifications:

Visible inspection: | ||

- Colour: | black | |

- Viscosity: A, B: | paste | |

- Density: | A: 1.47 g/cm3; B: 1.43 g/cm3 | |

- Mixing ratio (A : B by weight and by volume): | 1:1 | |

Mechanical strength: | ||

- Tensile shear strength on fasteners: (according to DIN EN 1465, sandblasted, sample thickness 1.6 mm) | Al/Al (cured for 7 days at 23 o C) | 16 MPa |

Al/Al (measured at 100 0 C) | 4 MPa | |

- Compression shear strength (MPa) ( DELO Standard 5 | Pretreatment: Annealing | at approx. +23 °C | 7 d) | FR4/FR4 | 26 MPa |

PA6 / PA6 | 11 MPa | |

PMMA / PMMA | 12 MPa | |

PBT/PBT | 14 MPa | |

PETP/PETP | 15 MPA | |

CFRP/CFRP | 19 MPa | |

PC/PC | 18 MPa | |

ABS/ABS | 8 MPa | |

- Tensile strength: | 10 MPa | |

- Peeling strength ( sand-blasted, cured for 7 days at 23 o C) on Steel/steel samples: | 8 N/nm | |

- Elongation at tear: | 60% | |

- Young's modulus: | 100 MPa | |

Physical properties: | ||

- Shore hardness A: | 90 | |

- Shore hardness D: | 50 | |

- Glass transition temperature: | 400C | |

- Decomposition temperature: | 1830C | |

- Coefficient of linear expansion: | 167 ppm/K | |

- Water absorption: | 0.3% | |

- Volumetric resistivity ( Based on VDE 0303-30): | >1012 Ω.cm | |

- Surface resistivity ( Based on VDE 0303-30): | >1013 Ω | |

- Creep resistor CTI M (DIN IEC 60112) : | 600 M | |

- Dielectric strength ( Based on DIN EN 60243-1): | 17.7 kV/mm | |

- Shelf life (Time calculated from the day you received the goods) | 6 months, stored at +15 ~ +30 0C with the unopened original container. | |

For more detailed information, please contact us.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing, curing systems, and technology transfer from DELO in Vietnam!