Surface pretreatment methods before bonding

10:14 - 30/09/2020

Efficiently bond materials with adhesive, surface cleaning is a must. Not only that, to achieve outstanding performance in adhesion (adhesive strength after adhesive), the materials need to be surface treatment before gluing. HUST Vietnam introduces the following three popular surface treatments below that significantly increase efficiency when using DELO adhesives.

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Efficiently bond materials with adhesive, surface cleaning is a must. Not only that, to achieve outstanding performance in adhesion (adhesive strength after adhesive), the materials need to be surface treatment before gluing. HUST Vietnam introduces the following three popular surface treatments below that significantly increase efficiency when using DELO adhesives.

1. Use specialized solution DELOTHEN

To remove grease and dust on the surface of the material, we can use the DELOTHEN solution sprayed onto the surface with a distance of 20 ~ 30 cm. Then wipe with a fine cloth and injected with dry air before applying adhesive.

This is one of the simple but effective solutions for cleaning and activating the surface, enhancing the adhesion of the adhesive to the surface of the material. DELOTHEN is designed as a spray bottle ready to use and extremely convenient. This product can also be designed with a large capacity tank incorporating an automatic spraying system for industrial-scale according to customer requirements.

2. 2. Surface pretreatment by plasma method:

There are two ways to pretreat the material surface using the plasma method: normal pressure plasma and low pressure plasma.

- At normal pressure, the ionized gas stream is generated by a high voltage source, contact with the surface of the plastic material, making the plastic surface polarized and helping to improve adhesion when the adhesive is wet.

- At low pressure (usually applied to products with complex shapes such as grooves, narrow holes, capillaries, etc., and matrix composite materials). The reaction gas is an inert gas, supplied into a vacuum chamber and ionized by electrical energy. This low-pressure environment enables this inert gas to react evenly with the surface of the material, creating a surface that is more polar and adhesion better to the adhesive while still wet.

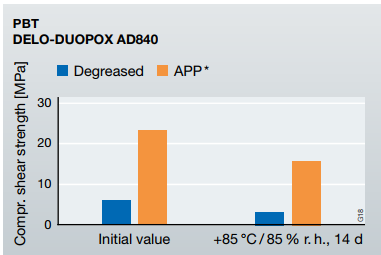

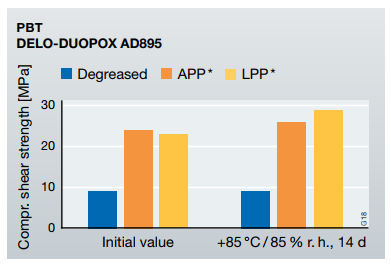

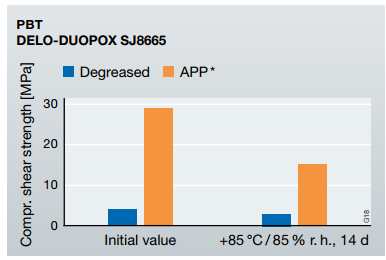

Some diagrams below show a marked change in the bond strength of the surface pretreatment:

|  |

· Degreased: normal remove grease · APP: Atmosphere pressure plasma · LPP: Low pressure plasma

|  |

Typically, treatment of surface plasma at normal or low pressure both offers a significant increase in adhesive strength, especially for semi-crystalline resins such as PBT, PA, and PPS. The above diagrams show a significant increase in the shear strength of the PBT plastic sample treated by plasma compared to the sample only treated with grease on the surface of the material (3 ~ 4 times higher).

In the test conditions of 85 °C temperature, 85% humidity, after 14 days, on the same material as PBT with different DELO-DUOPOX adhesives, all samples are surface-treated. maintain a significantly compressive shear strength, even higher than at the beginning.

Therefore, for the plastic sample to have high adhesion strength, the initial surface pretreatment is extremely important. Applying plasma treatment technology to achieve the best adhesion effect.

3. Sand abrasion technology combined with DELO-SACO surface blasting

Combining both abrasive sandblasting and surface cover spray techniques to create mechanical bonding for difficult to bond surfaces, increase bonding strength and resistance to environmental impacts for materials after sticking.

The effectiveness of surface treatment before gluing has been studied and proven by DELO.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing and curing systems, and technology transfer from DELO in Vietnam.

For more information about DELO adhesive products, please contact us!