Introduce:

DELO-PUR9xxx adhesive group (PUR = PolyUrethane) is a 2-component adhesive line, originating from modified polyurethane, curing at room temperature or accelerating when heated to +80 o C, and is a durable adhesive line. Pull apart the layers and pack them in a double glue bottle, making it easy to apply glue both manually and automatically.

Outstanding features:

- The glue is padded with inorganic mineral particles to strengthen the material's mechanical properties.

- The adhesive has a high viscosity, prevents creep when applying glue, suitable for large gaps that need to be bonded.

- Usage temperature range: from -40 °C to +150 °C depending on the type of glue and specific application.

- The adhesive is durable at high temperatures, has good solvent resistance, and is durable in the peeling test.

- The time to apply glue after mixing is only 5 to 30 minutes, enough for manual manipulation without the glue gelling and at the same time meeting the requirements for quick curing to increase production productivity.

- All glue labels meet RoHS standards according to directive 2015/863/EU.

Featured application

▪ Adhesives are suitable for structural adhesive applications, sealing, encapsulating electronic components, tools, machine parts, etc. Applications requiring high peel durability, airtightness, water, solvent resistance,…

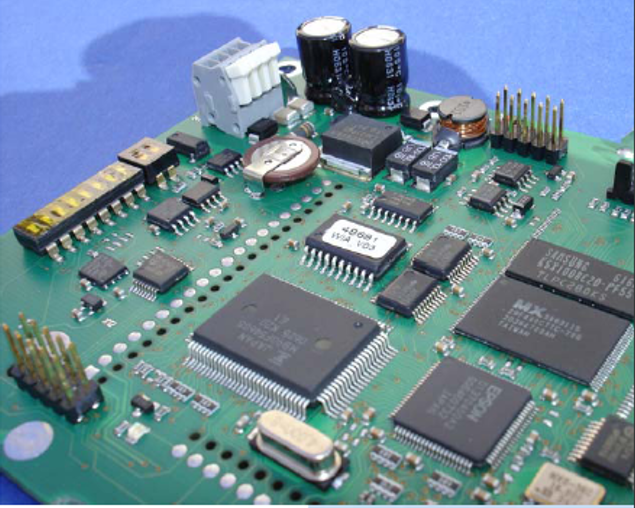

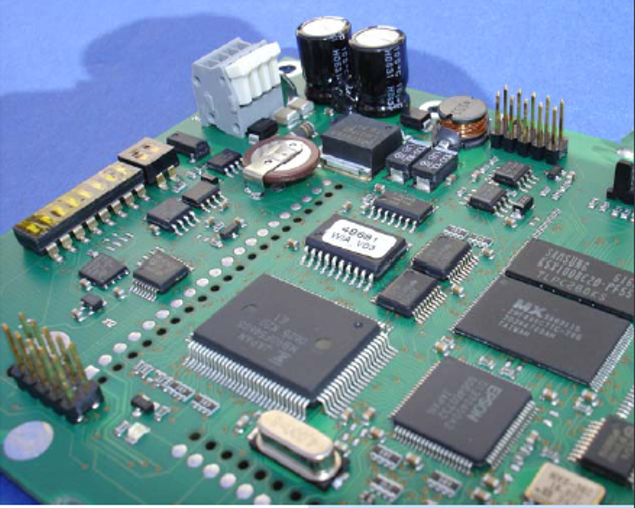

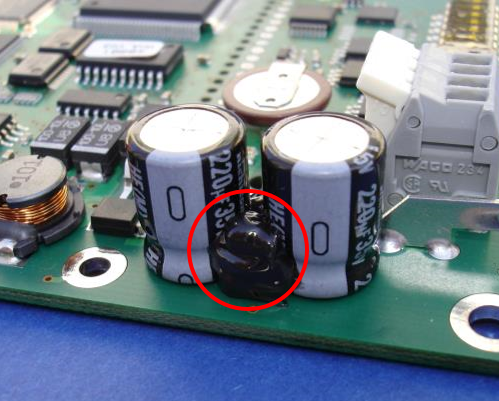

1. Fix the components on the PCB board

Fix inductors, capacitors, connection ports, etc. on the PCB circuit to prevent vibration of the components.

Material composition:

- Printed circuit board: FR4

- Components: Ferrite, PBT, Al, PET foil

Choose adhesive:

- DELO-PUR 9694

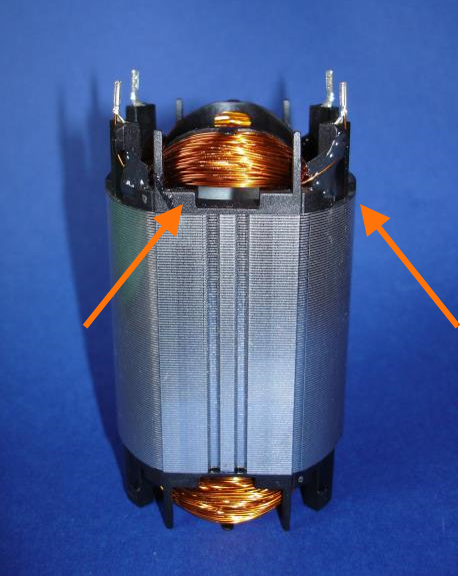

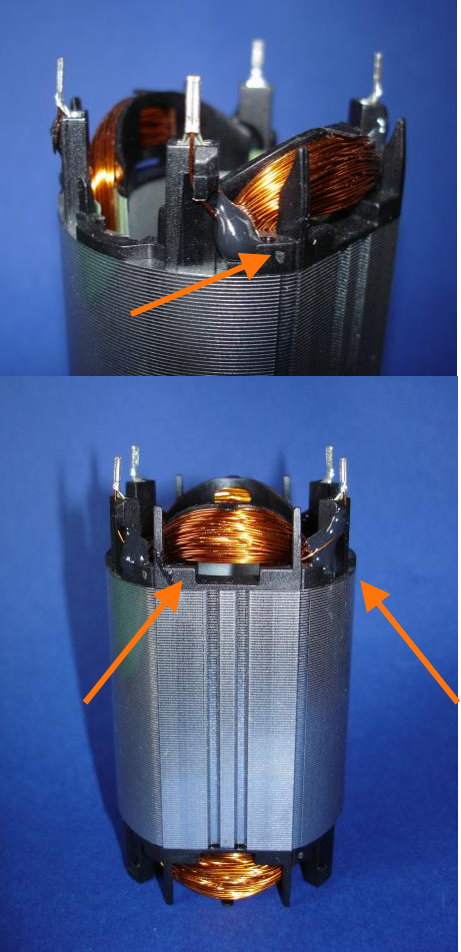

2. Fixed and anti-impact for stator coils in hand-held electric drill motors

Material composition:

- Support frame part: PA 66 GF30 plastic

- Copper wire: brass

Choose adhesive:

- DELO-PUR 9694

3. Adhere the corner strip to the wooden picture frame

Material composition:

- Metal: stainless steel.

- Wood

Choose adhesive:

- DELO-PUR 9694

Specifications:

Parameter | ||||||

Ingredient | 2-component adhesive, from modified polyurethane | |||||

Color | Black, opaque | Black, opaque | Black, opaque | Beige, opaque white | Black, opaque | |

Filler | Inorganic minerals | |||||

Application | Adhesive, sealing, casting | |||||

Usage temperature | -40 ~ + 125 oC | -40 ~ + 125 oC | -40 ~ + 140 oC | -40 ~ + 125 oC | -40 ~ + 105 oC | |

Processing time | 10 min | 5 min | 7 min | 30 min | 9 min | |

Storage time | 06 months | |||||

Initial curing | at 23 oC | 90 min | 30 min | 2h | 5.5h | 4h |

at 80 oC |

| 5 min | 5 min | 25 min |

| |

Final curing | at 23 oC | 72h | 72h | 72h | 72h | 7 days |

at 80 oC | 22 min | 10 min | 40 min | 90 min |

| |

Mixing ratio (vol.) | 1:1 | 1:1 | 1:1 | 1:1 | 10:1 | |

Density (g/cm3) | A (monomer) | 1.45 | 1.47 | 1.47 | 1.48 | 1.31 |

B (hardener) |

| 1.43 | 1.43 | 1.44 | 1.28 | |

Viscosity (mPa.s) | A (monomer) | 80000 | Pasty | |||

B (hardener) | 80000 | Pasty | ||||

Shear tensile strength (Theo DIN EN 1465, (MPa) | Al/Al (sand grinding, adhesive cured at 23oC for 7 days) | 16 | 23 | 16 | 16 | 3 |

2.5 (measured at 100 oC) |

|

| 3 (measured at 100 oC) |

| ||

Peel-off tensile strength (Steel/steel, adhesive cured at 23oC for 7 days) | 6 N/m | 6 N/m (Sand grinding) | 8 N/m (Sand grinding) | 10 N/mm | 4 N/mm | |

Tensile strength (Theo DIN ISO 527) (MPa) | 13 | 20 | 10 | 10 | 2 | |

Compression shear strength (MPa) | Glue dries at 23 oC, in 7 days |

|

| ABS/ABS = 8; CFRP/CFRP = 19; FR4/FR4 = 26; |

|

|

Elongation at tear | 20% | 3% | 60% | 70 % | 120 % | |

Young's modulus(MPa) | 500 | 1500 | 100 | 100 | <10 | |

Shore hardness | D 69 | D 75 | D 50; A 90 | D 50; A 90 | A 51 | |

Glass transition heat (oC) | 49 | 53 | 40 | 39 | < -50 | |

Thermal expansion coefficient | 162 ppm/K (25~140 oC) | 153 ppm/K (30~140 oC) | 167 ppm/K (30~140 oC) | 205 ppm/K (30~140 oC) |

| |

Shrinkage (%vol) | 3 %vol. | 1.5%vol. | 5%vol. | 4 %vol. | 2 %vol. | |

Water absorption | 0.24 %wt. | 0.3 %wt. | 0.3 %wt. | 0.3 %wt. | 0.8 %wt. | |

Destructive temperature | 225 oC | 194 oC | 183 oC | 221 oC | 236 oC | |

Dielectric strength (According to DIN EN 60243-1 standard) | 16.6 kV/mm | 12.3 kV/mm | 17.7 kV/mm | 17.6 kV/mm |

| |

Special properties | Meets ISO 10993-5: Meets fire resistance standards ANSI/UL 94 HB Flame Test | Meets VOC content requirements according to GB33372-2020, Meets fire resistance standards ANSI/UL 94 HB Flame Test. Very good solvent resistance | Meets VOC content requirements according to GB33372-2020, Meets fire resistance standards ANSI/UL 94 HB Flame Test. Very good solvent resistance | Meets ISO 10993-5: Meets fire resistance standards ANSI/UL 94 HB Flame Test. Very good solvent resistance. | Does not contain isocyanates, silicone, low transmittance, or high light absorption, Balances stretching force, and prevents creep when applying glue. | |

Contact us for more detailed information.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing technology, curing, and technology transfer from DELO in Vietnam!