The High Power Burn-in System HPB-5C

Model: HPB-5C

Manufacturer: MCC - USA

I. INTRODUCTION:

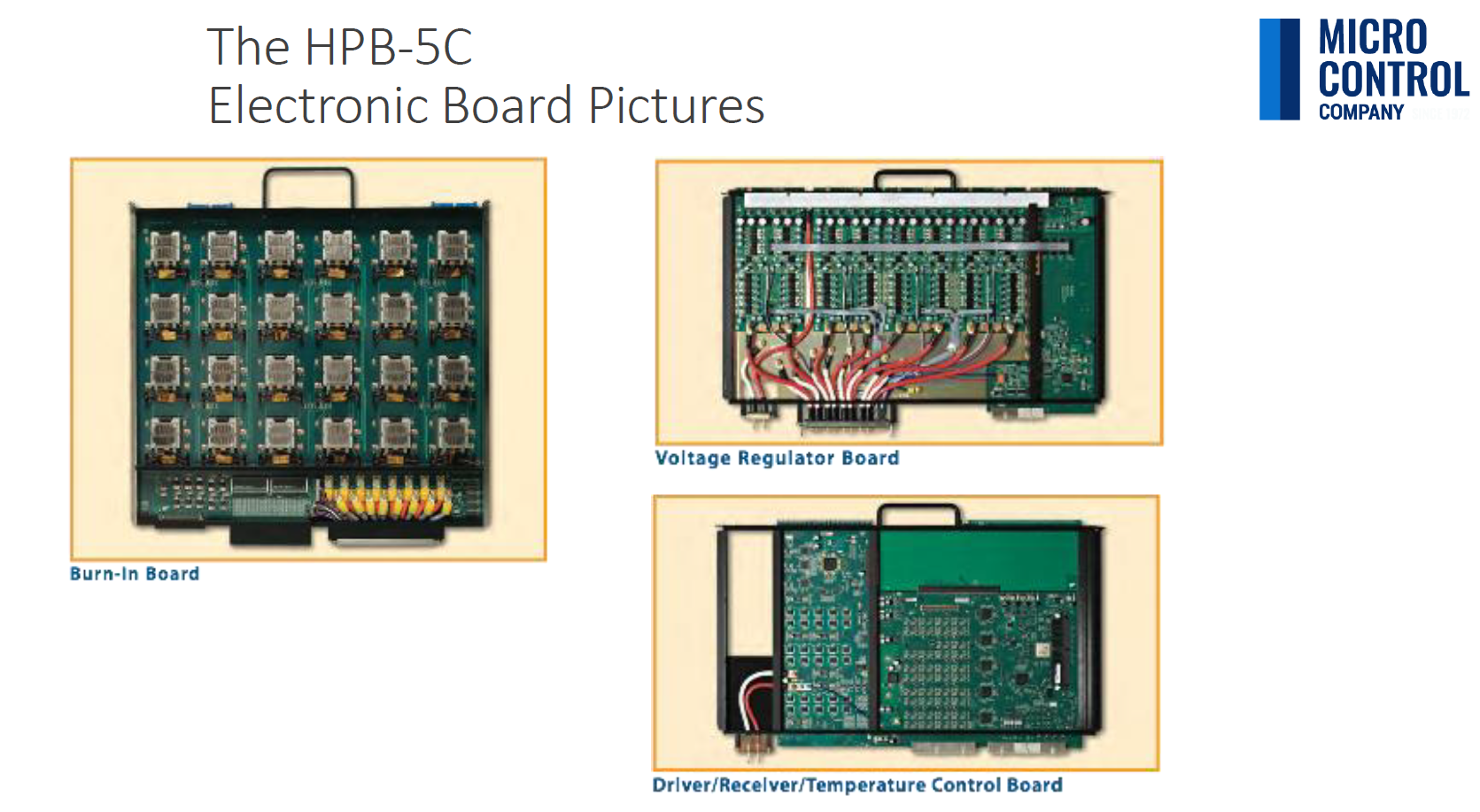

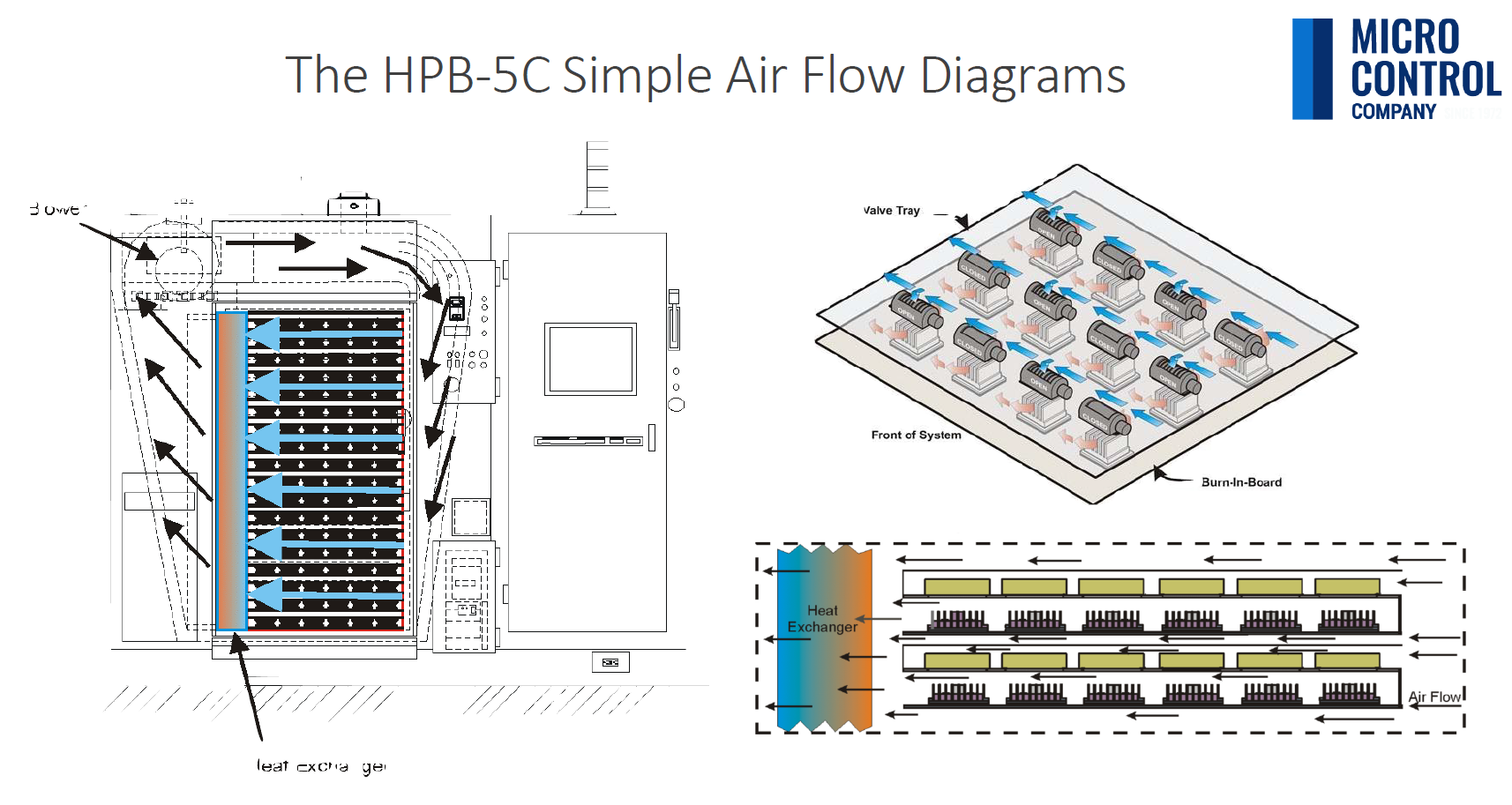

The HPB-5( is designed for diverse burn-in needs of medium-power VLSI devices. The oven is configured for 16 burn-in boards with up to 24 devices per board and 64M of vector memory depth. This configuration supports one pattern zone for each burn-in board. The system works in a conventional burn-in mode up to 150C.

II. FEATURED:

• Individual temperature control for each device under test up to 150 Watts

• Individual temperature control for each device under test up to 150 Watts

• Up to 16 pattern zones.

• Tests devices up to 150( using individually variable airflow control.

• 128 digital 1/0 signals per burn-in board, plus 24 chipselect drivers. (Optional 256 1/0)

• 16 programmable voltage regulators per burn-in board.

• Up to 1080 Amps programmable voltage regulators per burn-in board.

• System capacity of up to 384 devices.

• 64M vector memory per burn-in board.

III.BENEFITS:

- Testing capabilities for high-power devices

- Ensures proper thermal stress for each device

- Measures device temperature more accurately

- Testing is more cost-effective due to greater system capacity resulting in higher throughputs

- Exercise and test high pin count devices or more parts in parallel

- Run large numbers of test vectors without time-consuming reloads

- Up to 16 different pattern zones with one burn-in board per zone

- Up to 2000 Watts of device under test power available per slot

- Translate and run device test programs

- Clock devices with built-in self-test (BIST) at high speed

- Flexibility to test complex devices

- Stores failure information without slowing down the test

- Test both logic and memory functions

- Flexible system protection control for more detailed reports of failure

Customers please contact HUST VIETNAM for detailed advice