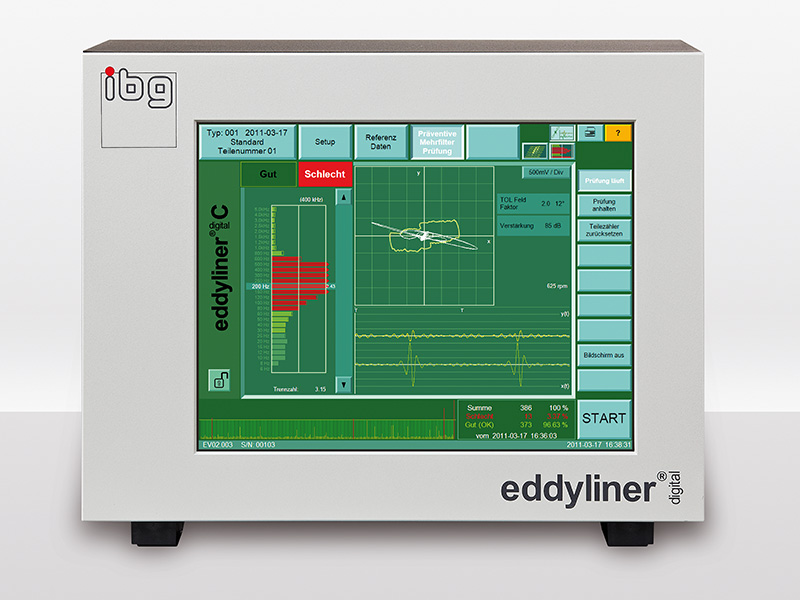

eddyliner® C Eddy Current Instrument Description

The eddyliner® digital C instrument distinguishes itself with compact design and concentration on one channel crack and grinder burn detection with one probe and combines that with the well known ibg test reliability and ease of operation. The ergonomic interface enables correct and simple operation via touch screen. All functions and test results are captured at a glance

Digital processing of the measuring signal with unique processors, immediately after the pre-amplifier guarantees the greatest possible stability of test results.

The eddyliner® is based on the ibg system concept proven for decades. All eddy Current test probes and rotating heads of the ibg system family can be used. The eddyliner® is therefore recommended not only for the solution of new tasks but also as an upgrade for existing production machines to be equipped with state-of-the-art eddy current technology. It is also portable eddy current test equipment for your production parts.

Up to now, competitive instruments require sophisticated and time-consuming manual determination and setting of suitable filter band, phase angle and gain. We replace that by the ibg exclusive development of Preventive Multi-Filter Technology (PMFT) with automatic tolerance zone creation. This quantum leap in the eddy current technology, unique to ibg worldwide, establishes a new standard for quality in crack and grinder burn detection.

During material data recording (calibration) with PMFT, surface areas of several good parts are scanned, and the good surface eddy current “noise“ is recorded simultaneously in each of 30 band pass filters. Tolerance zones, enveloping 360 degrees, are automatically created within each filter band, capturing the allowable eddy current “noise“ from good parts. The eddy current signals of good parts are the result of surface roughness and material properties. Thus, the thirty tolerance zones store the part specific fingerprint of the good parts. Additionally, edge effect, hardness profile run out, eccentricity, etc. of the good parts are calibrated during material data recording. Pseudo rejects are, therefore, reduced considerably without losing visibility to real flaws. Real flaws are now automatically detected no matter their frequency content or phase angle content. Even unexpected part flaws that can be detected by eddy current are reliably detected.

This unique “good-part-only-concept“ enables setup within a few minutes. Simply record an adequate number of good parts. One keypress switches to Preventive Multi-Filter Test and testing can start. That‘s all!

General:

- Probes

A variety of eddy current crack detection probes are available with different scan width, sensitivity and design. customized models for special applications are designed and manufactured in house. Our compact and precision rotating heads eddyscan® H and eddyscan® F operated with our eddyliner, can be the solution for cycle time optimised crack tests. Monitoring of probe cable break guarantees maximum reliability for continuous operation. - Lift-off compensation

Eccentricity of a workpiece can be offset electronically thanks to lift-off compensation. This function requires special lift-off compensation probes. - History

The ibg multi-colored histogram displays the test results of all reference data, the latest 100 bad parts and up to 1,000 good parts at a glance. They can be evaluated later, an essential function when reference parts are fi rst recorded and afterwards cross checked in the laboratory. If it turns out that some assumed NOK parts need to be added to the reference parts it is just a matter of one keystroke. - Suspend

The suspend function enables areas on components such as holes not to be tested. - Part types

50 part types with all settings and reference data can be stored in the device memory and switched manually or via PLC for automated processes. - Display

Test results are shown as bargraph, xy-diagram with tolerance zones, x(t) and y(t) or three-dimensional C-scan, selectable. The C-scan (or cascade diagram) provides a plannar display of a cylindrical surface to enable visualisation of defect position and length. - Frequency range

The carrier frequency is selectable within a range of 3 kHz and 10 MHz in 21 steps. The filter frequencies of the 30 band pass filters are spread in the range 6 Hz – 5 kHz. - Data storage

Test results, part types and device settings are stored internally on a robust flash memory and externally on an USB stick. Test results may additionally be logged via Ethernet. A ring buffer logfile records all actions and allows fast debugging for service purposes. - Activating test

Start of test manually at the touch screen, via PLC or an optional start button. - Automation without PLC

Direct control of sorting devices, paint marking systems or indicating lamps is possible with the integrated 24 V DC (2.5 A) power supply, providing a low cost solution for small automated systems without an additional PLC - Remote control

The eddyliner® is remotely operable by every network computer via VNC viewer software. - Access protection

This eddy current test instrument provides a multilevel access authorization concept that operates by pin code - Help function

The user always has access to a context sensitive help function on the device screen which often renders a look into the manual unnecessary. - Languages

Included are: German, English, Spanish, French, Italian, Czech, Polish, Portuguese, Chinese, Hungarian, Japanese, Korean and Russian. Other languages as option. - Screen

Tough 10.2” TFT touch screen, color display, resolution 1,024 x 768 pixel, operable with gloves

Housing

- completely sealed and thus can be used in a dusty production environment

- desktop housing, inclinable by folding feet

- 19” rack installation as option

Connections

- IO-ports

optically insulated interface for PLC connection with 32 inputs and 32 outputs - network

Gigabit-Ethernet-network - printer

commercially available printers may be connected via USB 2.0 or Ethernet to printout test results - XVGA

XVGA interface allows connection to a monitor or projector, an essential feature for training courses.