Advantage:

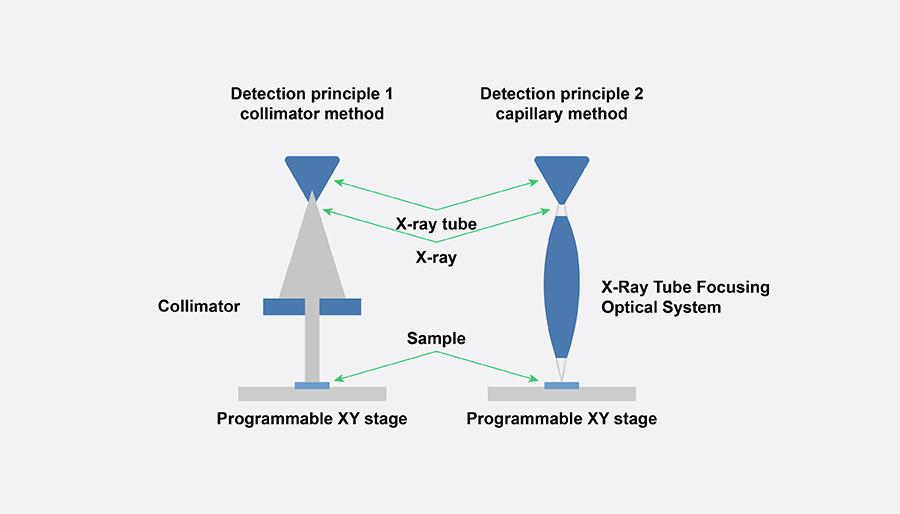

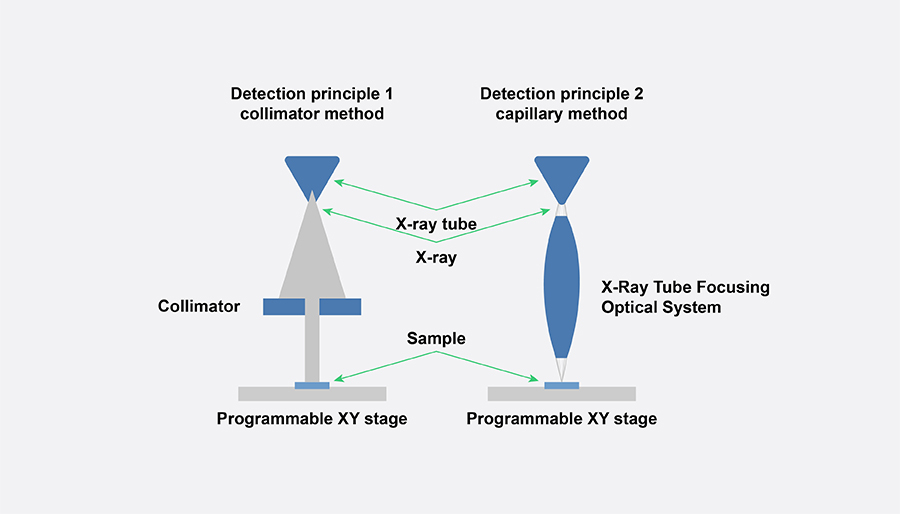

Multi-collimator: Multiple collimators are optional or multiple collimator combinations are automatically switched by the software, which can flexibly deal with parts of different sizes.

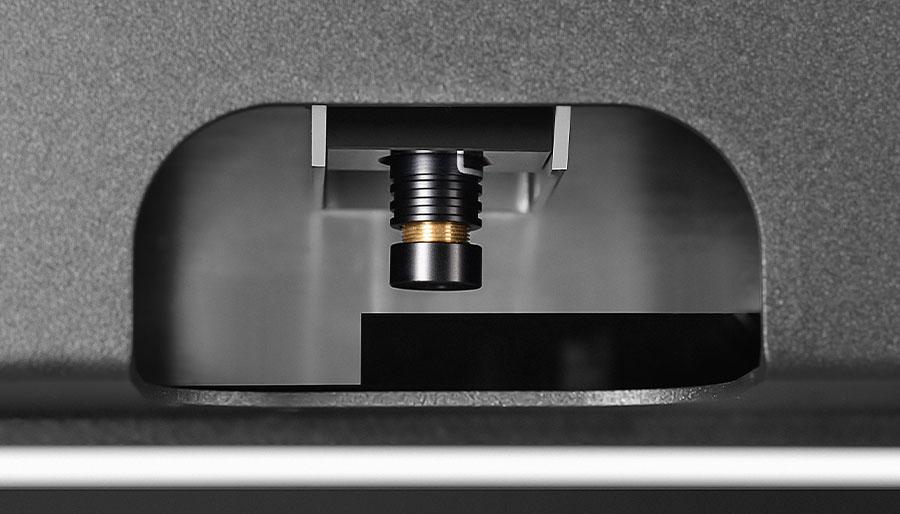

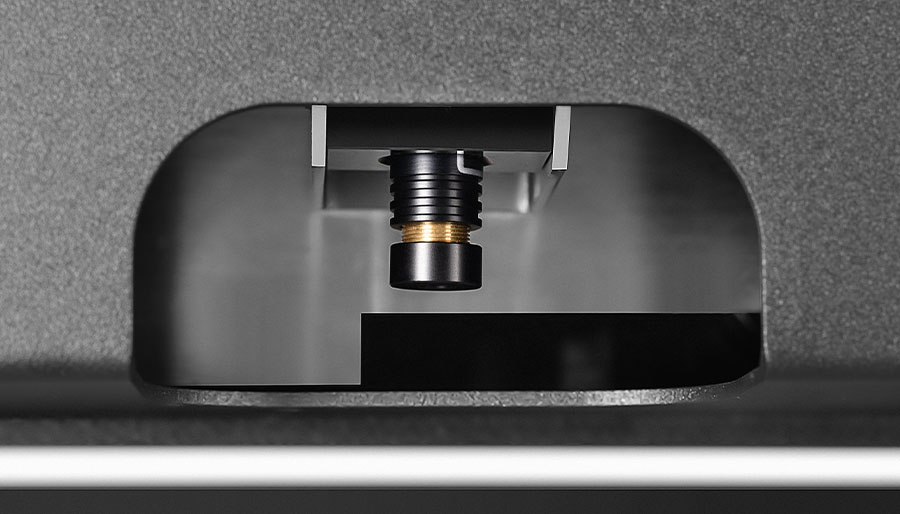

Up-bottom Design: The instrument adopts the Up-bottom design, which can easily achieve fast, accurate, stable and efficient measurement of super-large, irregular, small, and even liquid samples.

Highly performance detector: We choose Si-PIN detectors suitable for multi-element coatings. Compared with traditional gas proportional counters, Si-PIN has better resolution, lower background noise (highest S/N ratio) long-term stability and longer service life.

- Auto focus: Samples are automatically brought into focus in seconds, regardless of sample thickness or size. Samples can be measured from distances as far as 80 mm. The instrument is ideal for measuring parts with recessed areas, or for measuring multiple samples at different heights.

Programmable automatic displacement sample stage: The instrument is equipped with an automatic platform, which can easily realize automatic measurement, and can prepare and measure samples faster, thereby increasing the analysis volume.

- One-touch measurement: The instrument is equipped with intuitive and intelligent analysis software, which is easy to operate. Anyone can test samples without training. Just click "Start Test", and the test results can be obtained in tens of seconds.

Applications:

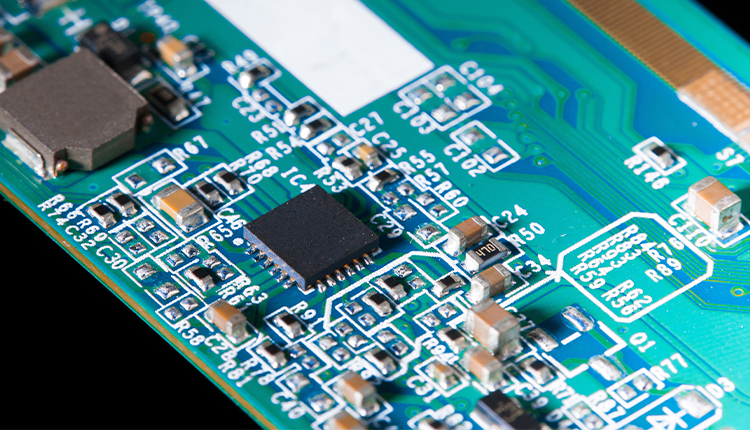

- Printed Circuit Boards: Au/Ni/Cu/PCB; Sn/Cu/PCB; Au/NiP/Cu/PCB; Ag/Cu/PCB; Sn/Cu/PCB; SnPd/Cu/PCB; Au/Pd/NiP/Cu/PCB.

- Connector Plating: In the electronics and electrical industry, the use of protective and wear-resistant coatings for electrical contacts is increasing. As the core component of the electrical connector, the surface treatment can improve the corrosion resistance and wear resistance of the contact, and can also optimize the transmission function of the contact to a large extent. The base material of electrical connector contacts is generally copper alloy, and the commonly used plating layers are: tin plating, gold plating, silver plating, nickel plating, palladium plating, etc.

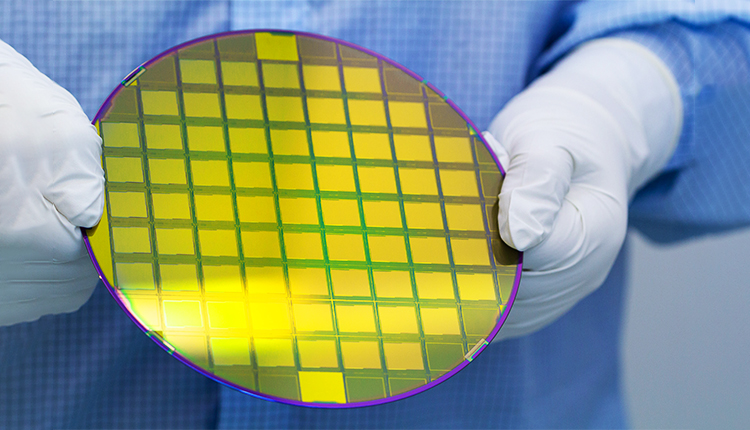

- Wafer Manufacturing (Semiconductor): Wafer refers to the silicon wafer used in the fabrication of silicon semiconductor integrated circuits. In the production process, the wafer needs to be electroplated, that is, a layer of conductive metal is electroplated on the wafer, and the conductive metal layer is subsequently processed to form a conductive circuit. As the basic material of the chip, the wafer has strict requirements on the electroplating layer, so the process requirements are also high. During wafer plating, the uniformity and thickness of the coating must ensure the quality of the wafer.

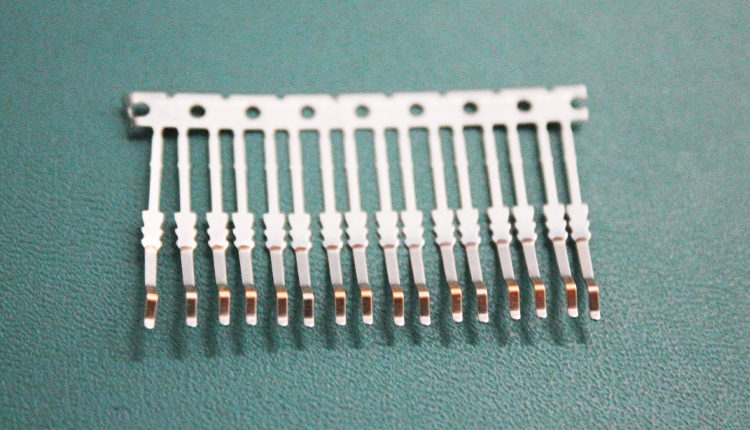

- Lead frame: The lead frame is a thin-plate metal frame that connects the contact points of the internal chips of the semiconductor integrated block and the external wires, and is a main structural material of the semiconductor package. In order to ensure the mounting/bonding performance in the packaging process, special surface treatment is required for the lead frame. Common lead frame plating elements include gold, silver, palladium, nickel, etc.

- Jewelry:

Specifications:

| The characteristics | Top-down measurement structure, XYZ measurement platform, MUTI-FP multilayer algorithm | |

| Scope of element | Na(11)—Fm(100) | |

| Analysis of the layer | 5 layers (4 layers + substrate) each layer can analyze 10 elements, composition analysis can analyze up to 25 elements | |

| X-Ray tube | 50 W (50 kV, 1mA) micro-focused tungsten palladium ray tube (target material is optional) | |

| The detector |

| |

| Collimator | φ0.05-φ1 is optional. Multi-standard is optional | |

| The camera | High resolution CMOS color camera, 5 megapixels | |

| Manual sample XY platform | Moving range:100mm x 150 mm | |

| Programmable XY platform | (Optional) | |

| Z-axis range of movement | 150 mm | |

| Sample bin size | 564mm × 540mm × 150mm (L x W x H) | |

| Overall dimensions | 664mm × 761mm ×757mm (L x W x H) | |

| weight | 120KG | |

| The power supply | AC 220V±5V 50Hz(The configuration varies slightly by region) | |

| Rated power | 150W |