TEST METHODS AND FORCE APPLICATION

TEST METHODS AND FORCE APPLICATIONRockwell DIN EN ISO 6508, ASTM E-18:

HRA - HRV; HR15-N/T/W/X/Y; HR30-N/T/W/X/Y; HR45-N/T/W/X/Y

HK 1, HK 2

Integrated conversions: DIN EN ISO 18265, DIN EN ISO 50150, ASTM E140

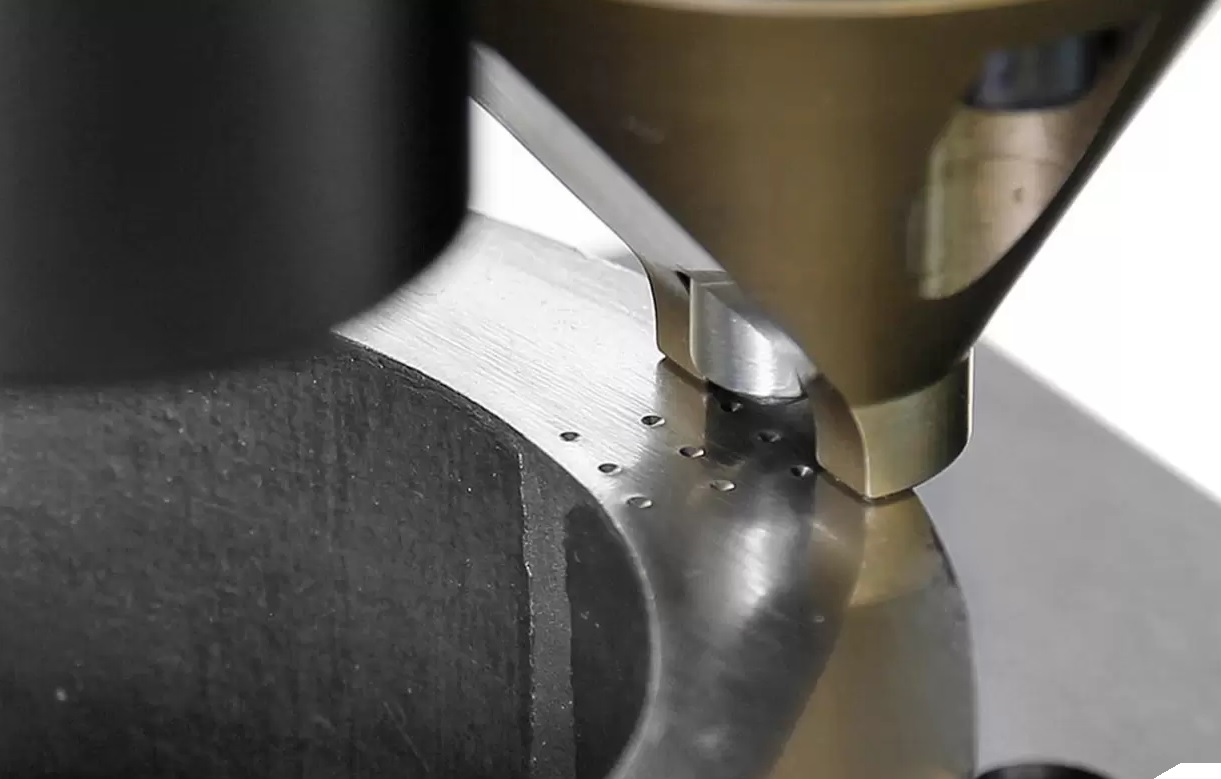

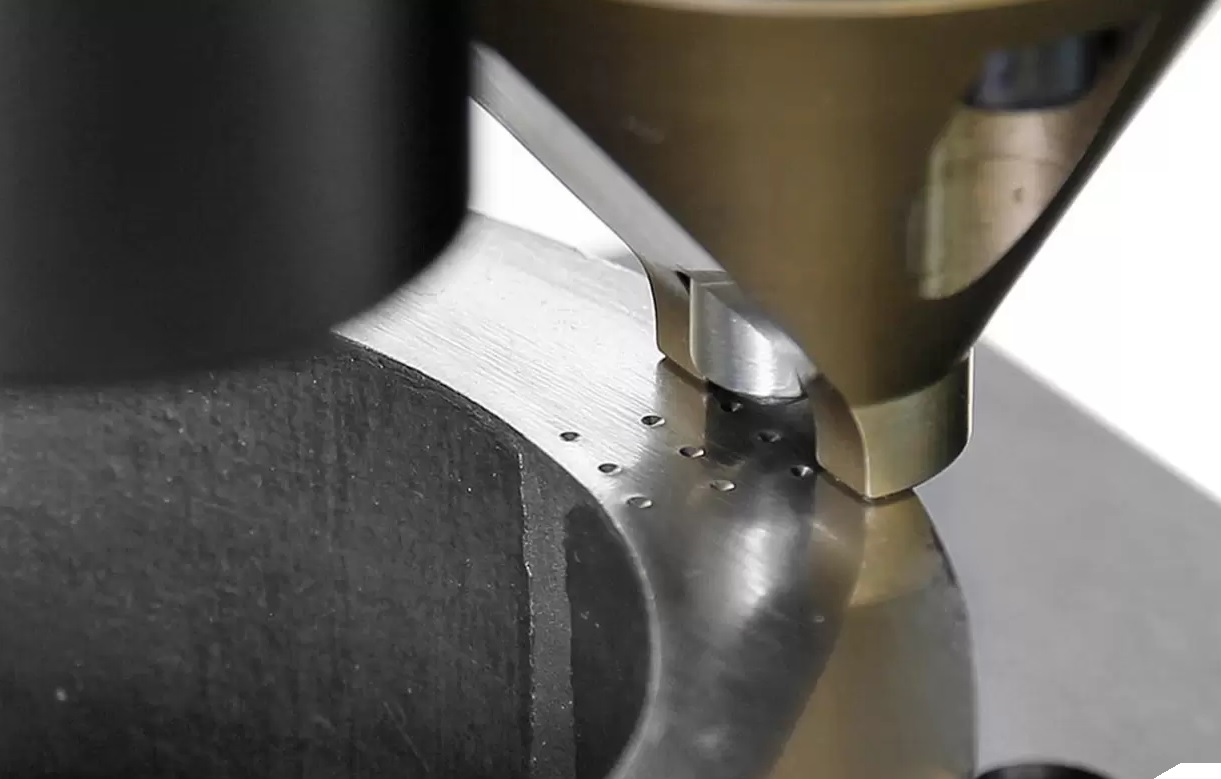

PIPE TESTING

Check pipes economically with the Q150A/A+ according to the applicable API standards.

MULTI JOMINY SAMPLE TESTING

Up to 8 samples can be placed in the Jominy sample holder for testing. The testing cycle is fully automatic and executed accor-ding to the norm.

ACCESSIBILITY TO NARROW TEST PLACES:

- LD lenses provide an increased working distance

- Collision proof

- Overview and analysis via optical system

- Field of view 0.2 - 40 mm

RAIL TESTING:

Another perfect application is the testing of rail profiles. The sample image camera function on the Q150A+ allows accurate and fast positioning of the individual test series.

WELDING TEST SAMPLES:

Ideal for welding test samples or visual test point positioning jobs - Test points can be norm-positioned based on the visual presentation

SOPHISTICATED SOFTWARE TOOLS:

Picture top: Image with graphic indentation size pre calculation Picture bottom: Graphic hint when test points are located to close to each other (3 x d)

CRACK LENGTH MEASURING K1C:

For evaluating the K1C value the 4 cracks are measured according to the norm. After that the MPa√m value is evaluated automatically.

Profile scanning:

Edge recognition:

Lens system:

Sample image camera:

EMBEDDED SAMPLES FOR CHD, NHD, SHD:

The sample patterns can be easily selected using the program. In addition to the single and row measurement, the user can select CHD, NHD and SHD.

The sample patterns can be easily selected using the program. In addition to the single and row measurement, the user can select CHD, NHD and SHD.

TECHNICAL DATA:

| Q150 A | Q150 A+ | |

|---|---|---|---|

Test force range | 1 - 250 kg (9,81 - 2450 N) | ||

Test height / Throat depth | 187 mm / 180 mm |

| |

Test height extension (option) | 377 mm |

| |

Height adjustment | v max 6 mm/s |

| |

Software | Qpix Control2 |

| |

Integrated optic system | (Option) |

| |

Camera | 18 MP color camera | 2x 18 MP color camera | |

| - | Yes | |

Test anvil/Cross slide | motoric 170 x 250 mm |

| |

Data interface | Interface PC-Hardness tester: 1x USB3.0 | ||

Weight of basic machine | 120 kg |

| |

Max. workpiece weight | 50 kg |

| |

Power supply | 230~1/N/PE, 110~1/N/PE | ||

Max. power consumption | ~ 240 W |

| |

| Single and multi sample holders, Jominy sample holder, Indenters, Lenses, Software modules | ||