Overview & Futures

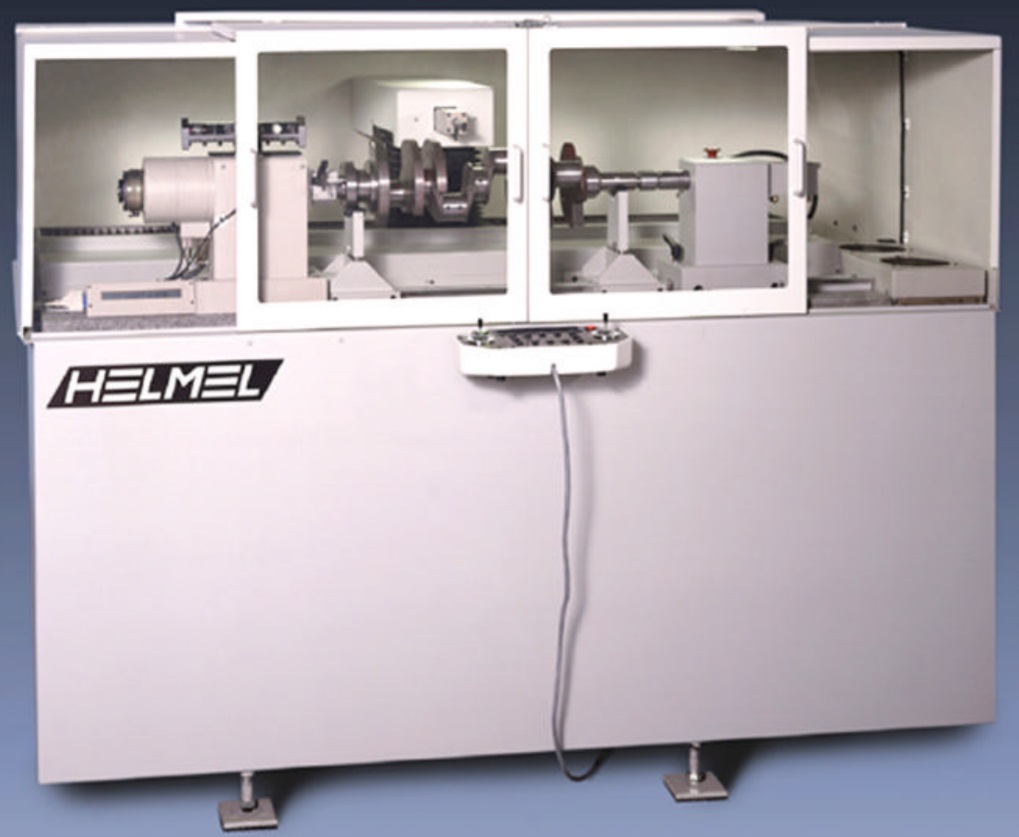

The Helmel Axium Shaft Measuring Machine has been developed to provide precise, automatic dimensional measurement of cylindrical and shaft-like manufactured parts. The system is hardened for use in production and on the factory floor, and requires minimal training for non-metrology employees.

Although the Axium has been designed as a 4-axis measuring system, it can be configured as a 3-axis system (less rotary axis) to fit your manufacturing needs. The Geomet metrology software is designed for measurement, verification and GD&T applications and resides on a powerful Windows based system along side.

The Helmel Axium shaft measuring machine presents a horizontal format, with a major cylindrical axis oriented left to right, duplicating the way most shafts are manufactured and ground. Parts are typically staged between centers, or on solid or rotating Vees. The system employs the Renishaw Touch Trigger or scanning probes for part sensing and can incorporate an automatic stylus changing system for totally automatic operation.

Measurement output can be made available for immediate accept/reject decisions based on nominal/tolerance features. Manual or automatic feedback of deviations may be used to control the manufacturing process. As a 4-axis system, single feature may be inspected while interlaced with rotation in the 4th axis. This unique feature provided by Geomet, allow single features to measure from two different sides.

The standard Axium shaft measuring machine is suitable for shaft lengths up to 900mm (36"), with a maximum diameter of 300mm (12"). Capacity for shaft lengths up to 1500mm (60") is available as an option.

INTRODUCTION VIDEO - High Precision 4-Axis Shaft Measuring Machine

- Built on a solid granite plate

- Precision ground steel ways

- Instrument grade precision bearings

- Fully covered for maximum protection

- Steel 0.5 µm encoder scales

- USB Delta Tau motion controller

- 0.002° rotary encoder

- Electronic touch probe interface

- Renishaw PH6/TP20 touch probe system

- Geomet 101 DCC software

- Pentium computer system

- Windows 7 and 8, 32 and 64 bit.

- Cabinet with monitor stand

- Optional protective enclosure

- Online access to software upgrades

- 1-Year CMM warranty

Specification:

Model | AXIUM |

Type | Automatic |

Probe | Renishaw Electronic touch probe |

Measuring range | X/Y/Z: 1115/175/250 mm |

Overall size | X/Y/Z: 1950/940/152 mm |

Resolution | 0.5 µm |

Repeatable | 3.5 µm |

Accuracy | 3.3 +L/167 µm |

Weight | 1360 kg |