Adhesive use in Retainer ring replacement bonding

15:11 - 30/09/2020

Due to space is limited and requires not to allow dirty glue on the smartphone camera lens while ensuring the lens allows the sensor to absorb maximum light. Thus, the black adhesive will improve significantly its effectiveness for Retainer ring replacement bonding. Besides, these components are very sensitive to heat, therefore require adhesive must be cured at low temperatures.

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

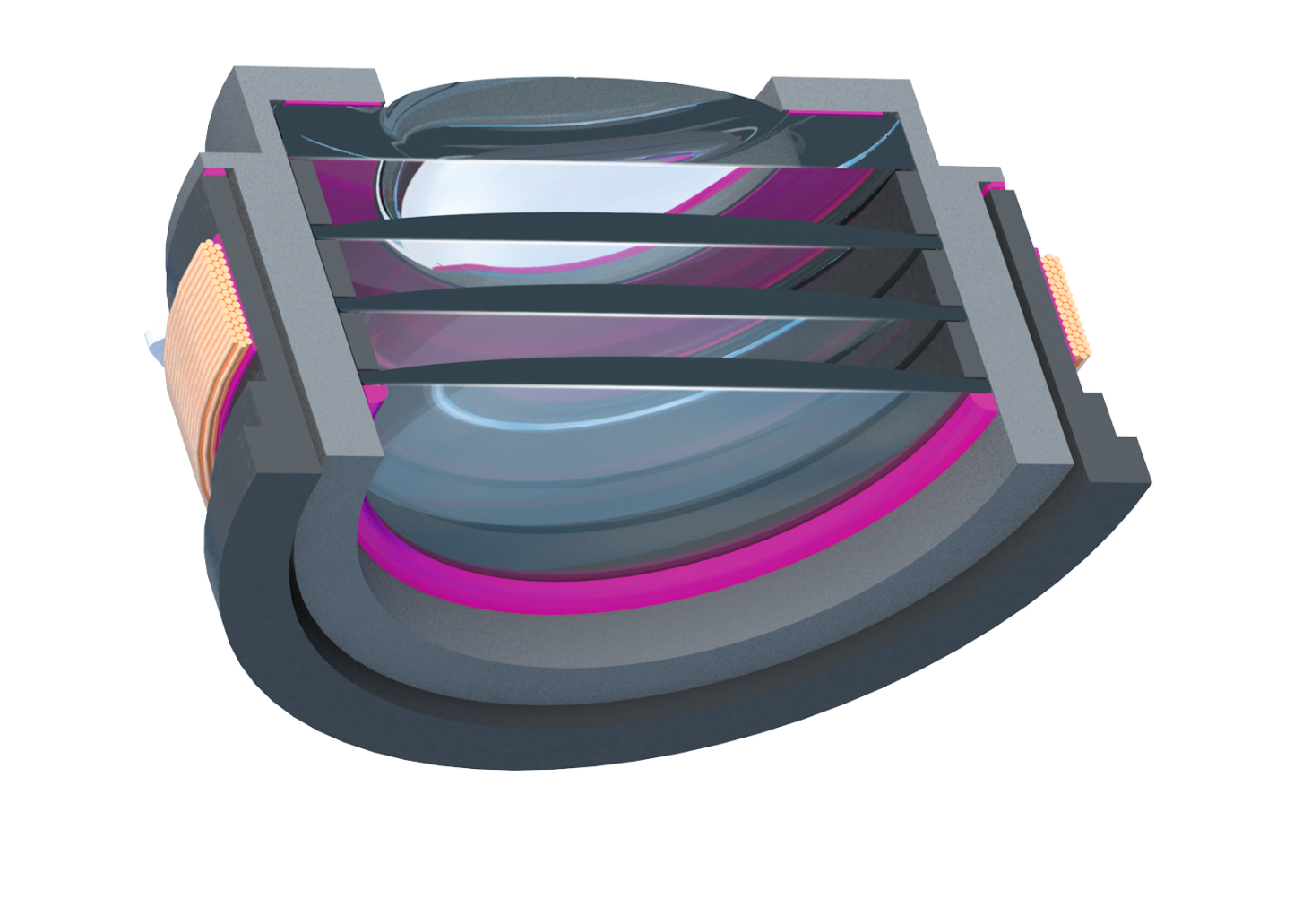

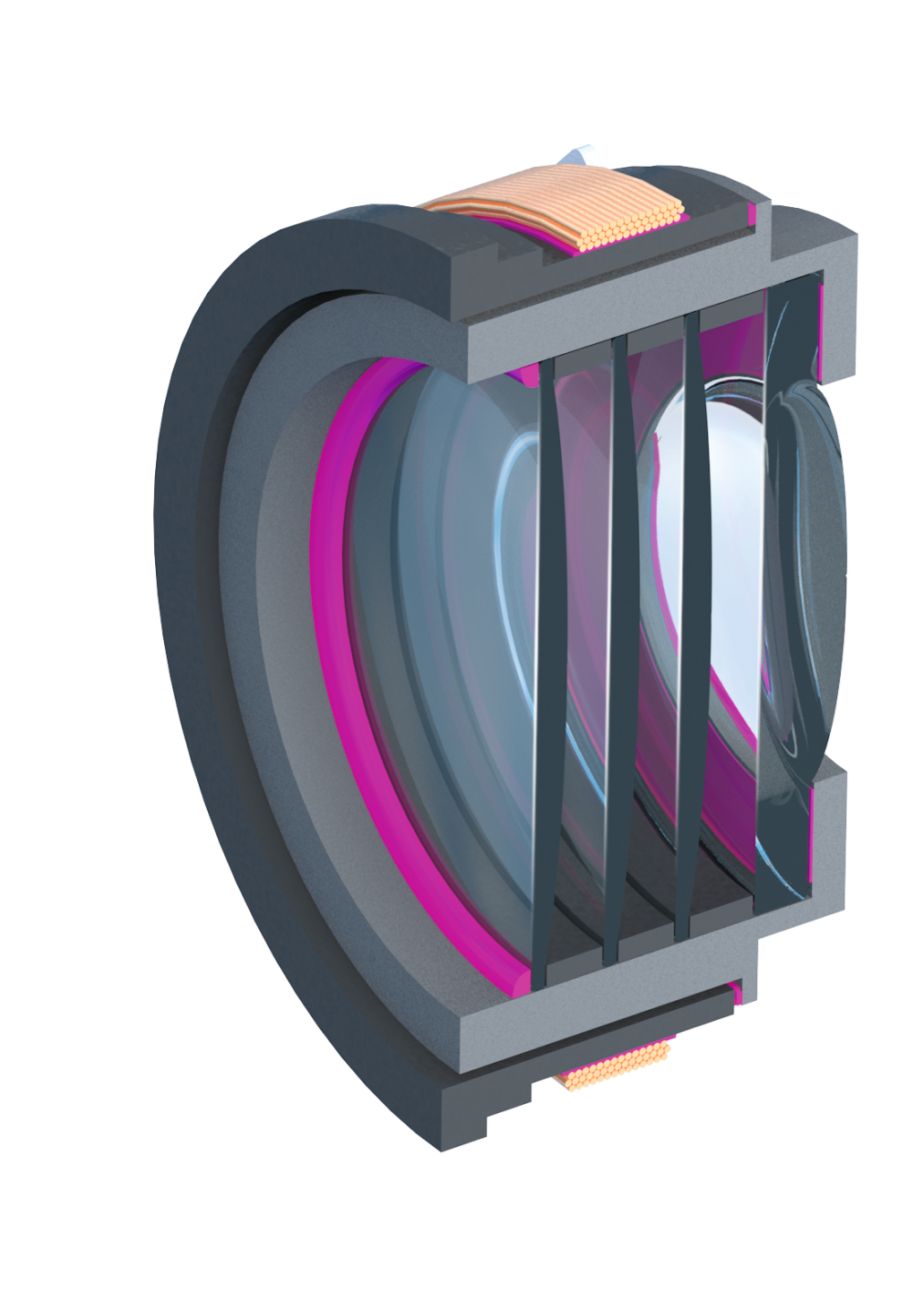

The camera module is one of the most complicated parts of a smartphone, the lenses and frames can only be linked together by adhesive.

DELO adhesives are not only outstanding in variety, but also bond to many different materials, for high tensile strength and resistance to harsh environments.

Due to space is limited and requires not to allow dirty glue on the smartphone camera lens while ensuring the lens allows the sensor to absorb maximum light. Thus, the black adhesive will improve significantly its effectiveness. Besides, these components are very sensitive to heat, therefore require adhesive can be cured at low temperatures. The special adhesive products of adhesives compatible with Retainer ring replacement bonding include: Some special adhesive compatible for lenses – barrel to holder bonding:

|  |

The adhesive characteristics requirements must be achieved:

- Replacing a threaded design to generate:

- Smaller components dimensions;

- Increase space for lens optics;

- Higher optics performance;

- Waste reduction/higher yield.

- Fast light prefixation: less than 1 s;

- Oven curing at moderate temperatures to protect lenses;

- Increased flexibility for stress relief;

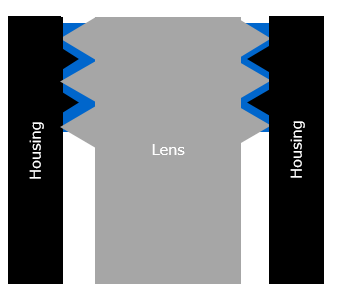

Can be designed by various methods, for example:

|

|

|  |  |

Threaded | Simple lens | Lens with ring | Steps in housing | Inclined housing |

The outstanding features of DELO adhesive:

- Low temperature curing <60oC;

- Adhesive can be only cured by UV / visible light;

- High performance due to fast curing;

- Reduce maximum cost thank to optimized adhesive dispensing;

- Waste out vapor very low, non-effective to optical components;

- Fixed adhesive by UV / visible light within 1 second;

- The adhesive is black, help to obtain light better;

- Good bonding for many materials as PC, ZEONEX, COC, and CO;

- Compliant with RoHS directive 2015/863/EU;

- Solvent-free and non-halogen criteria of IEC 61249-2-21.

The process of the bonding in lens camera:

|  |  | |  |

Needle: G27 | Alignment barrel/holder | Light curing | Heat curing | Focus measurement as follows customer process. |

Gap: 5~55 um | Option 1: | 4 x LED lamp | 30 min | |

Pressure: 4.2 bar | Option 2: | Irradiation within 4s | 80oC (begin temperature stable) | |

Volume: 0.8 ~2.0 mg |

| Intensity: 400 mW/cm2 |  | |

Dispensing: - Option 1: Only 4 drops - Option 2: Ring-shaped dispensing |

| Humidity curing: |

| |

24 hour | ||||

Room temperature | ||||

(Real curing time may be optimized by the customer) |

For more information about DELO adhesive products, please contact us!

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing and curing systems, and technology transfer from DELO in Vietnam.