Grinding processes on camshafts are as a matter of principle difficult and can regularly cause residual stress conditions exceeding the specified rate or even cause grinder burn defects like annealing or re-hardening zones in the area of the ramp or the nose.

Crack formation cannot be excluded when producing composite camshafts where single cams are either shrunk by temperature effect on the shaft or joined under pressure. Where in the past the structure conditions from the heat treatment process was often 100% inline tested by means of eddy current, nowadays the focus of interest is more and more a non-destructive 100% test for cracks and grinder burn.

Well, it is a basic requirement for a dynamic eddy current crack test that the probe has a constant distance to the surface, a constant speed and is as perpendicular as possible moving over the test part. Therefore these tests are limited to rotational-symmetrical or flat test parts.

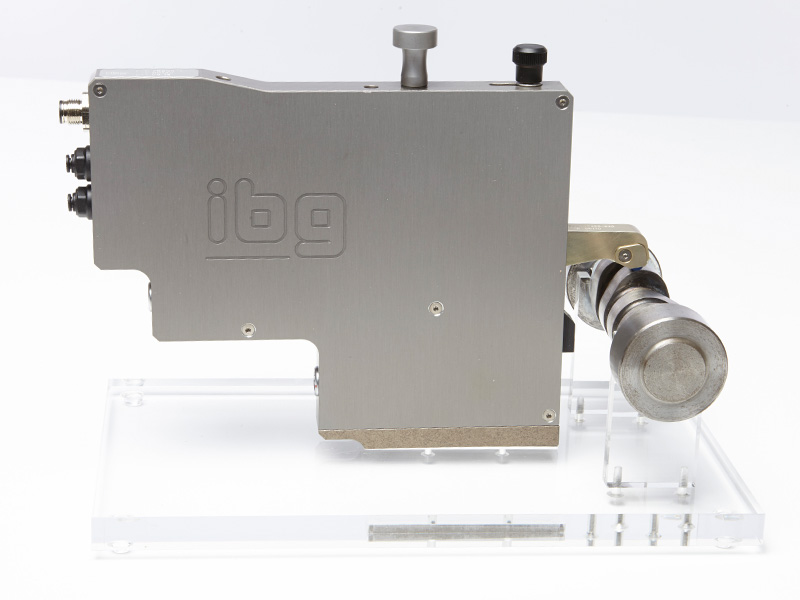

The development of our cam testbox enables exact tracking of the shape of the cam and thus achieve crack and grinder burn test results which are in no way inferior to results of rotational-symmetrical parts. The testbox may also smoothly follow the shape of pump lobes.

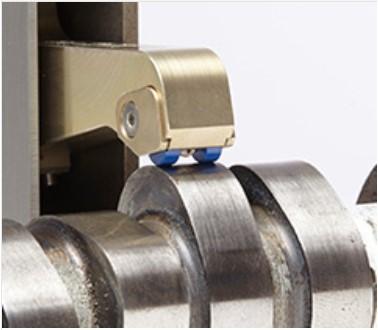

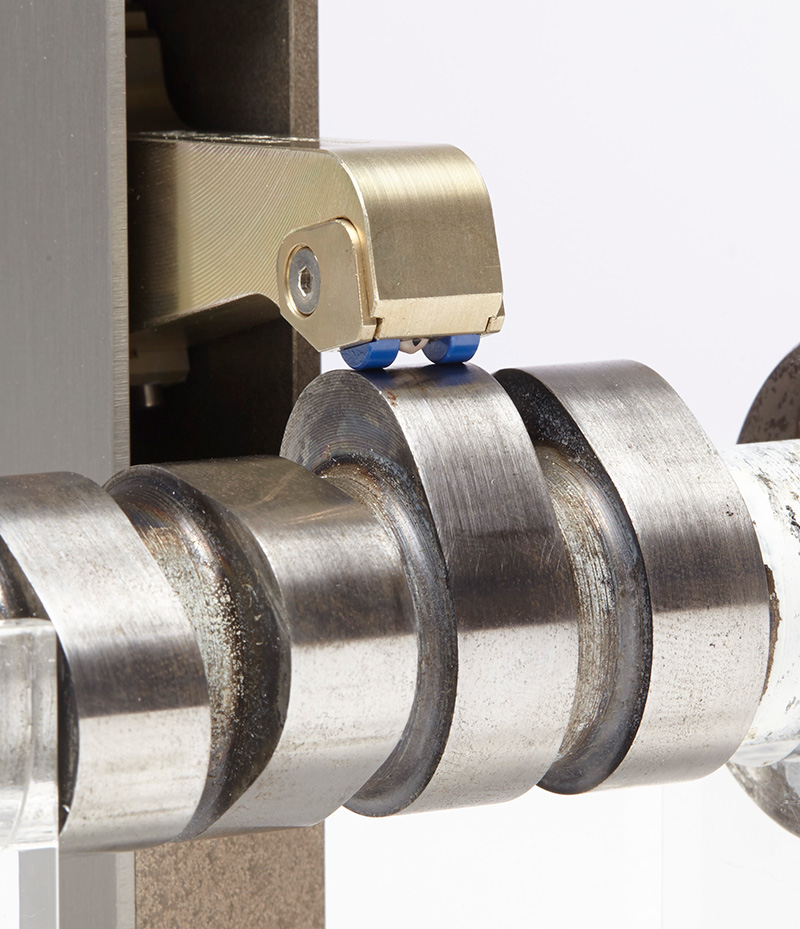

All that is possible with the ibg spherical X-type probe with a visual range of almost 180°. It is placed between two wear-resistant as well as exchangeable and pivotable ceramic disks. With them, the probe arm contacts the cam and follows its shape. The probe arm is equipped with a double pneumatic cylinder, which is like a spring in the one direction to follow the shape and in the other direction it lifts the probe arm from the cam when the system is returned to home position for loading/taking the camshaft. This kind of solution is capable of realising rotational speeds of the camshaft of up to 250 rpm depending on shape of cam. Originating from an effective probe width of 1.5 mm the testbox is moved during the test by the test system over wider cams in order to scan the entire lateral cam surface.

The testbox may be equipped with an additional structure test probe. At the beginning of the test cycle, the cam noses are positioned in front of the structure test probe by the rotary axle one after the other and are tested within milliseconds. This test guarantees for composite camshafts that unhardened cams which can slip through unintentionally into the joining process are reliably detected before the camshaft is mounted in the motor.

The testbox is equipped by default with an inductive sensor which sends a trigger signal to the test instrument once per revolution.

The eddyvisorC is able to work with up to 16 crack detection probes simultaneously and independently on your camshaft. Thus the 100% crack and grinder burn test can meet cycle times of fast production lines.