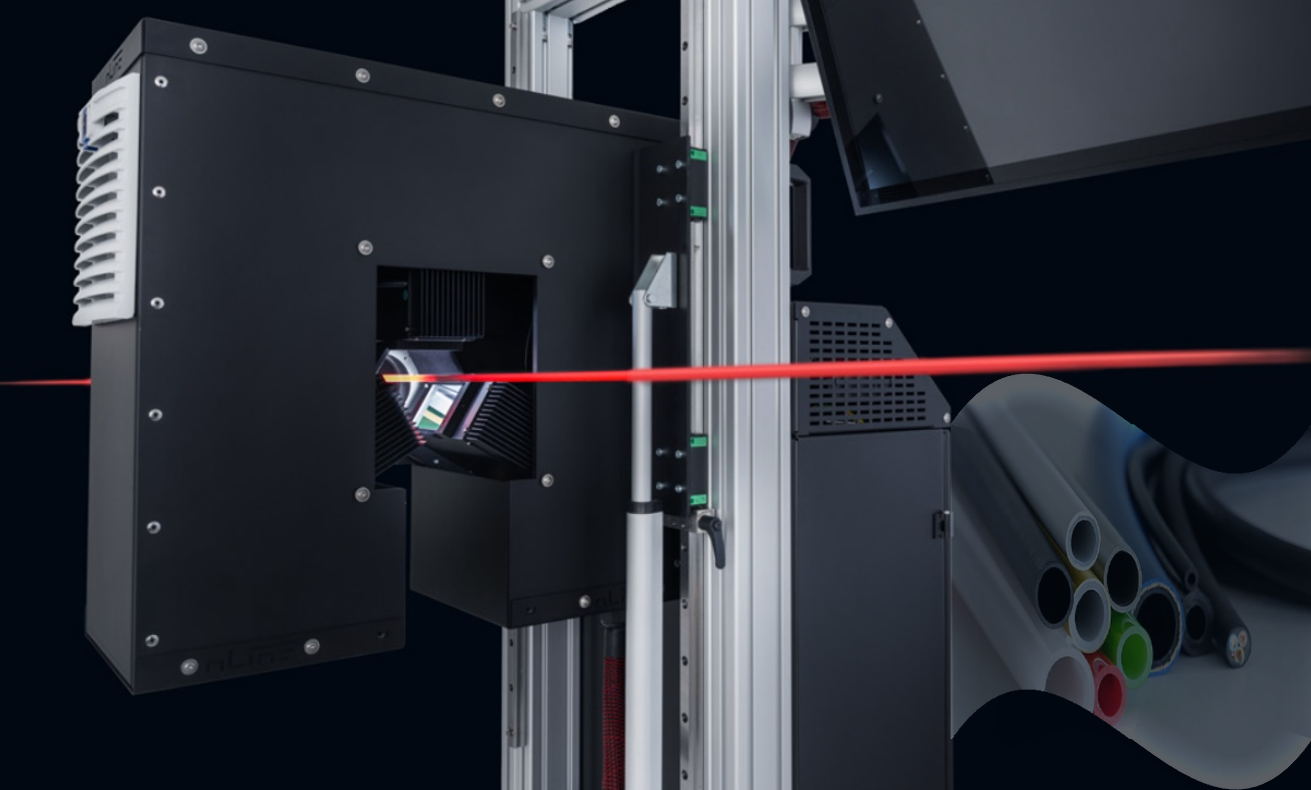

nLine - High-End Inline Quality Inspection Systems for Extrusion Products More precision, efficiency, and safety in the manufacturing of cables, wires, tubes, hoses, and ropes. With artificial intelligence and edge computing, we elevate your optical quality control to the next level.

|  |

Overview & Highlight

|  |  |  |

Simple Setup Easily create new products from qualified parts in minutes | AI on the edge No cloud connection required – for fast and secure data processing | Versatile in use Speed: 500 mm / min Diameter range: 0.5 - 165 mm | Low maintenance Minimal cleaning and maintenance effort |

|  |  |  |

Seamless Connectivity ProfiBus, ProfiNet, OPC UA | Ready use 24/7 Temperature 5–45 °C | | Process safe Insensitive to water droplets and dust particles on the product surface | Full integrable Single source software & hardware – simple & seamless integration, even in existing system concepts |

nLine - The Future of Visual Inspection Systems

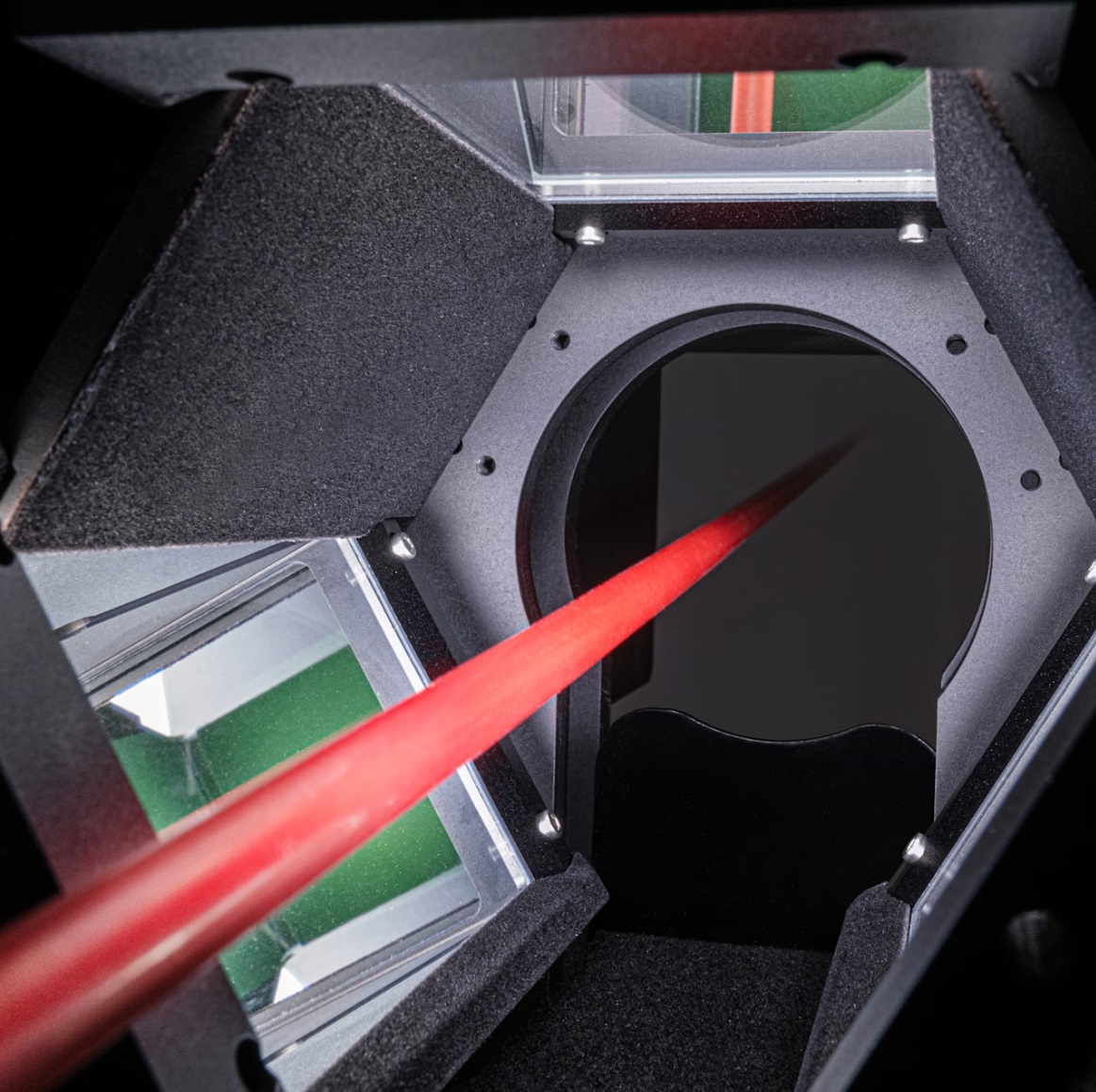

| nLine is our answer to the challenges you face in the production of high-quality extrusion products. With the help of three high-speed cameras, the entire product surface is continuously monitored. Any deviation is signaled and documented in real time. This allows a wide range of product and quality features to be analyzed reliably and easily – both directly inline during ongoing production and in individual inspections. The system is available in different versions and can be adapted to a wide range of requirements. Thanks to the Teach & Go approach and AI on the Edge, 100% inspection density and traceability can be achieved for any suitable extrusion product within a very short time. The wide range of possible applications and the extensive range of functions of our 360° inspection solution also help to significantly reduce investment and maintenance costs as well as integration costs. |

Specification

| Physical Attributes | nLine S (3-camera) | nLine M (3-camera) | nLine L (4-camera) |

| Dimensions | 978 x 520 x 1820 mm | 978 x 520 x 1820 mm | 1450 x 550 x 1850 mm |

| Weight | 125 kg | 125 kg | 200 kg |

| Product detection | |||

| Max. speed | 300 m / min | 500 m / min | 100 m / min |

| Min. diameter | 0.5 mm | 2 mm | 30 mm |

| Max. diameter | 2 mm | 30 mm | 165 mm |

| Electrical | |||

| Lense | Motorized | Motorized | Motorized |

| Operation temperature | 5°C - 45°C | 5°C - 45°C | 5°C - 45°C |

| Power supply | 230 VAC (50/60Hz) | 230 VAC (50/60Hz) | 230 VAC (50/60Hz) |

| Comsumption | 800W | 800W | 1000W |

| Ingress Protection | IP20 | IP20 | IP20 |

Areas of Application

|  |  |  |

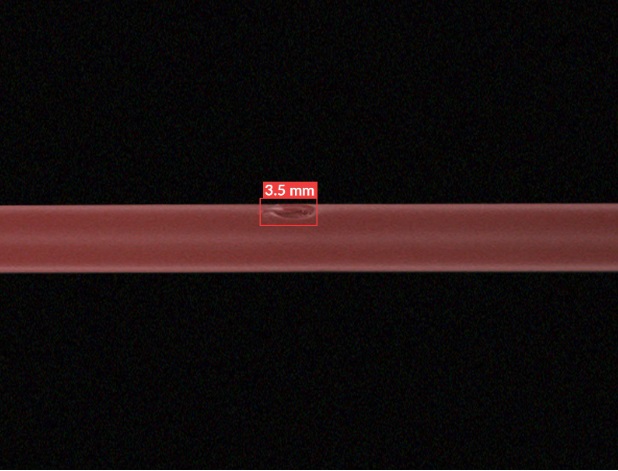

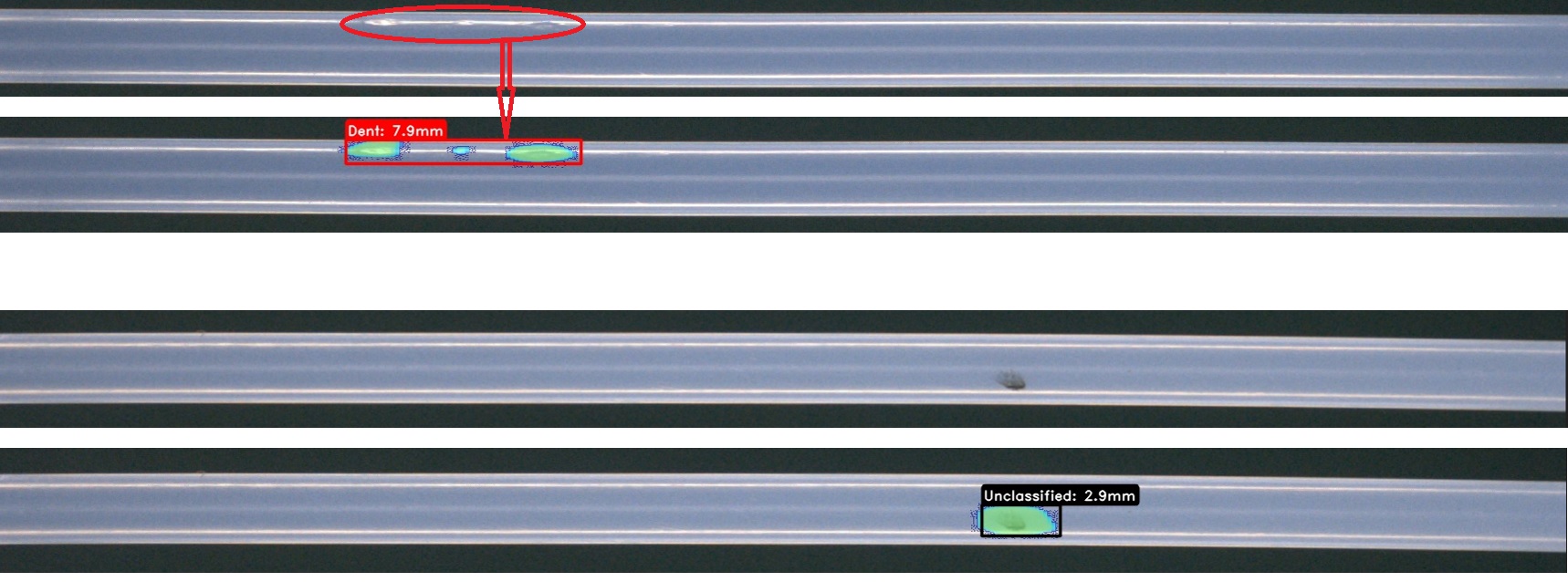

Surface inspection Breaks, cracks, cuts, holes, dents, pimples | Knots & Diameter Deviations Detection of Knots & Necking | Checking color Single color, multicolor, gradient, rotating | Inspecting imprints Markings, codes, lettering, serial numbers |

Operation Principle

| Installation Integrate nLine directly into the production line | |

Teach-in Define quality requirements with a master sample | ||

Training nLine processes collected data | ||

System ready nLine is ready to examine the learned product | ||

Product analysis Detection of surface anomalies in real time | ||

Reporting Analytical data is sent to your system |

Real Application for Reference

Electric cable - production line

Copper wire production

Cable, tube, pipe ... production line

Medical infusion tubes production line