OVERVIEW

ACV-16041 Series is a High speed Automatic optical nut sorting machine.

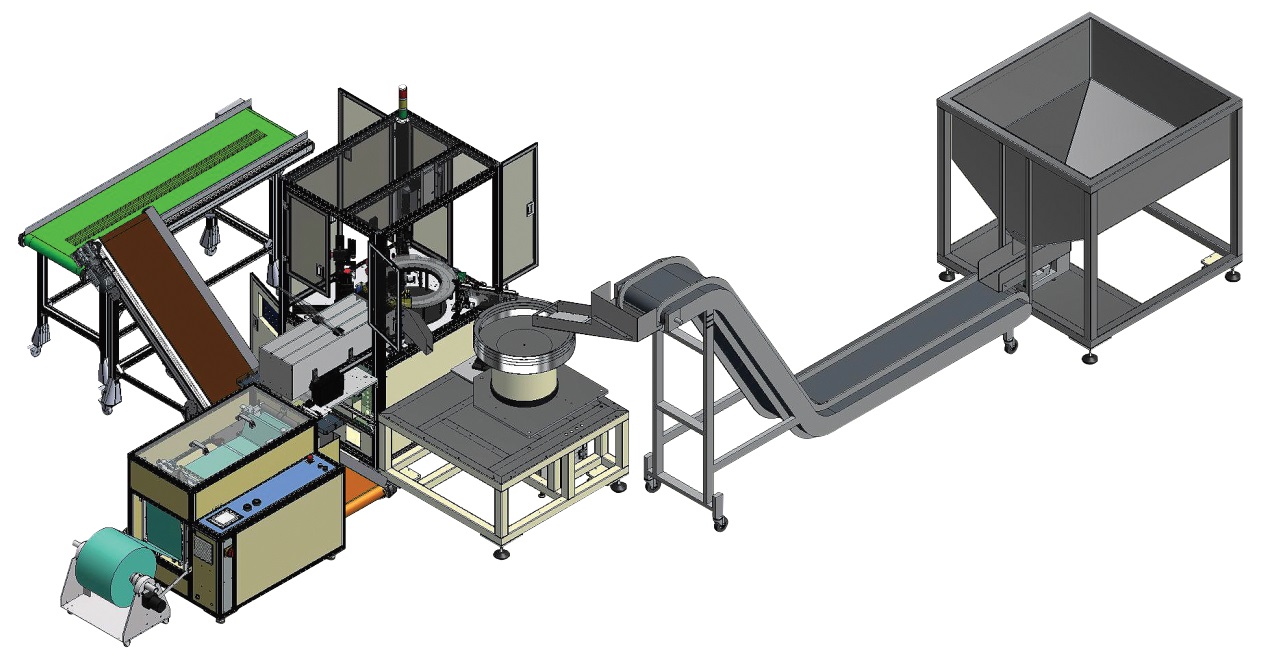

Structure of system:

- Auto feeding: Vibration bowl

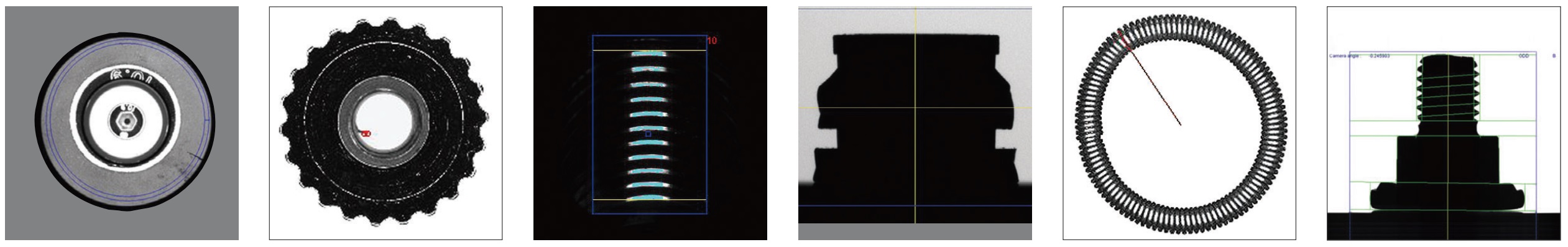

- Auto inspection: Includes optical & lighting (Germany CCD Camera), Inspection software (OCR - Optical Character Recognition is an optional), rotating table (Steel or Glass)

- Sorting system: OK/NG sorting in automatically, sorting according to range of tolerance, recognize / inspect defect, comparision

Moreover, after sorting stage, The system should be integrated with auto packing device, conveyor in order to create a fully automatic system.

APPLICATION SCOPES

ACV-16041 Series is often use to inspect small parts in the field of Fastener, rivet contacts , micro screw, micro parts manufacturing (Suitable for small parts with size at 0.5mm)

For example: screws of mobile phone, MP3, PDA, notebook, digital camera.

SPECIFICATIONS

| Size range | M0.5 ~ M4; Length: <25mm |

| Speed | 600 - 1200 pcs/min, depend on feeding speed |

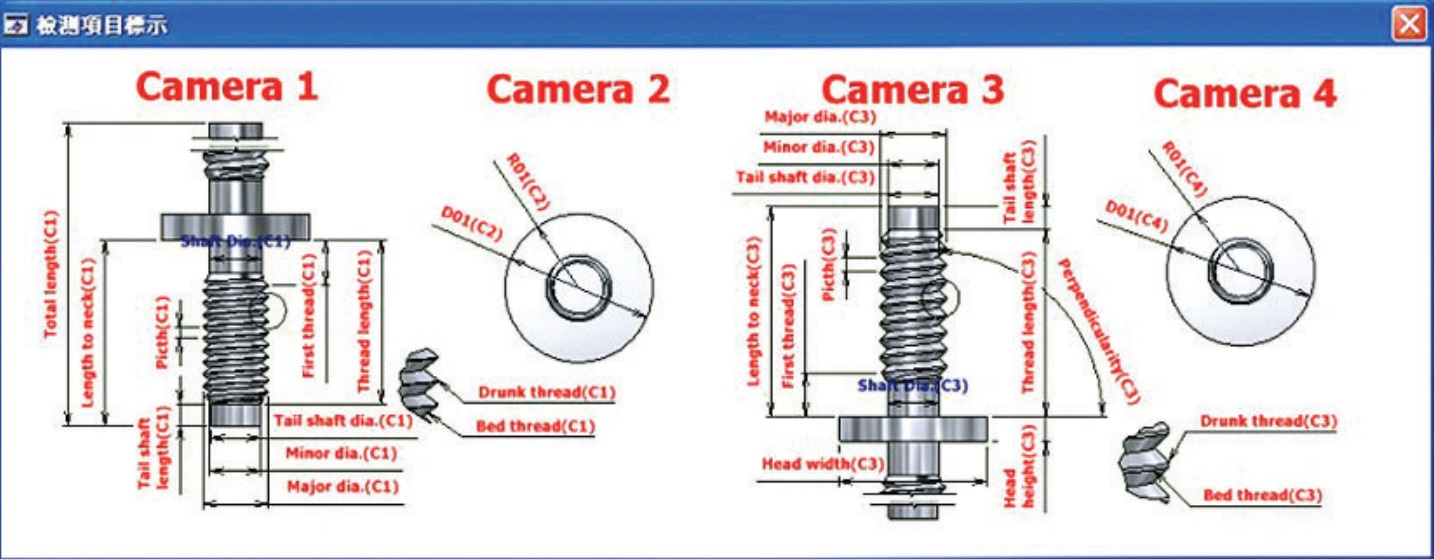

| Optical system | Highly magnified CCD camera / light source sets |

| No. of Camera | 1 - 6 (2 cameras is standard) |

| Outlet | From 1 to 2 bins for OK parts From 1 to 4 bins for NG parts |

| Software | Friendly GUI, easy to learn and use |

| Optional | Eddy Current Structure Testing System, OCR system, 360-degree camera module, packing system, telecentric lens, auto hopper system |

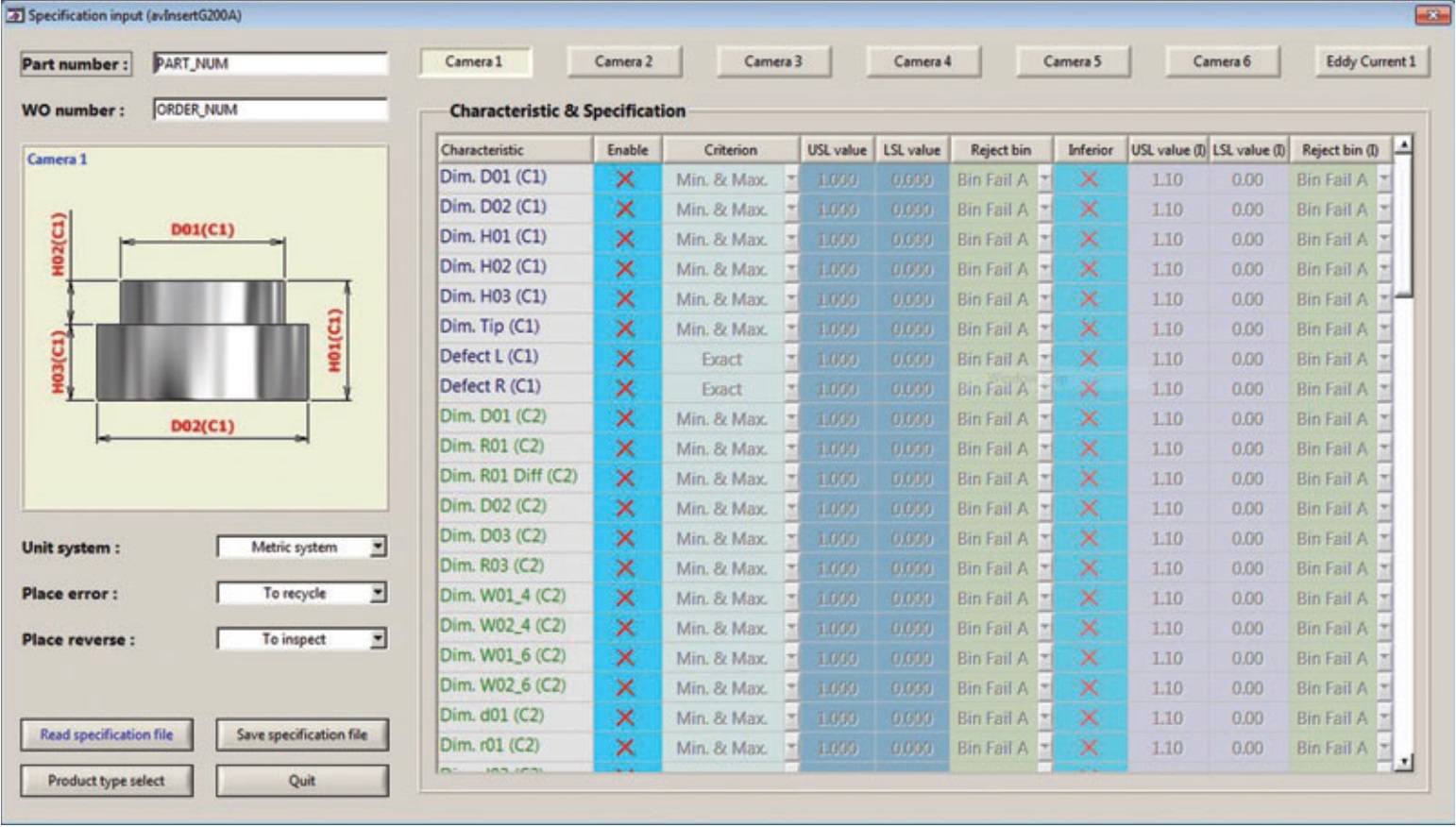

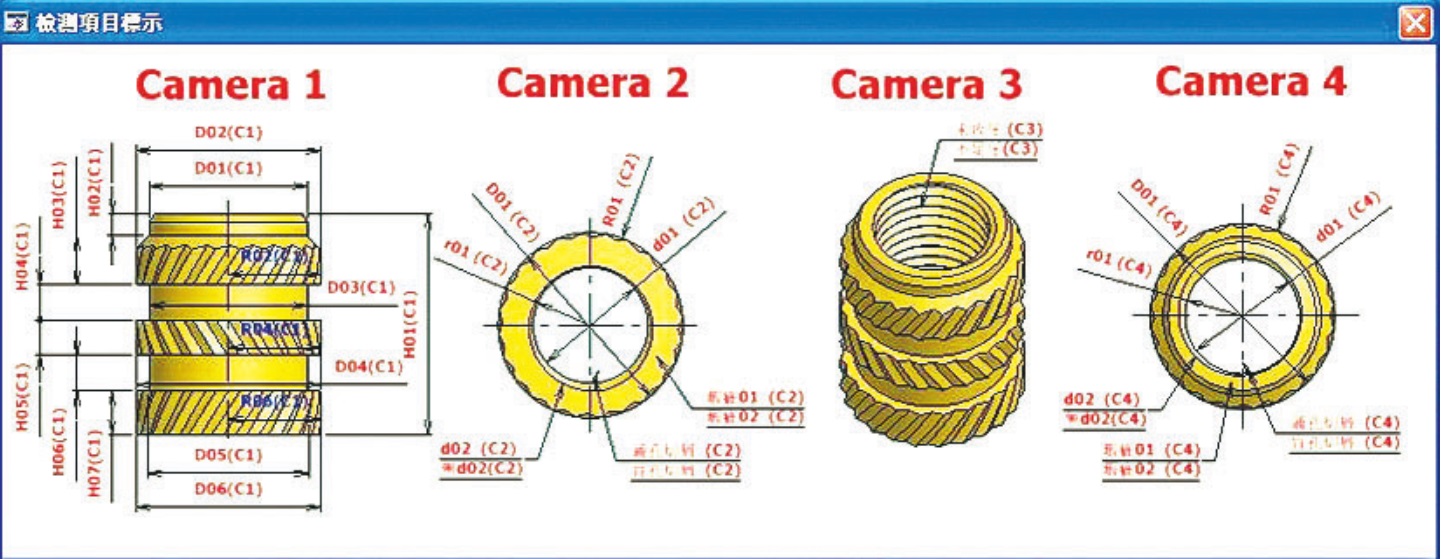

| Inspection parameters | Fastener parts head width / height / pinhole depth / recess shape / burr in recess/ spiral thread / thread I.D. / thread E.D./ neck length / shank vertical / screw length / first thread / drunk thread / head crack / plating / insert nut thread / burr / dimension / etc. |

| Power supply | AC 220 - 240V, 50/60Hz |

| Dimensions | 1065mmL×860mmW×1,855mmH |

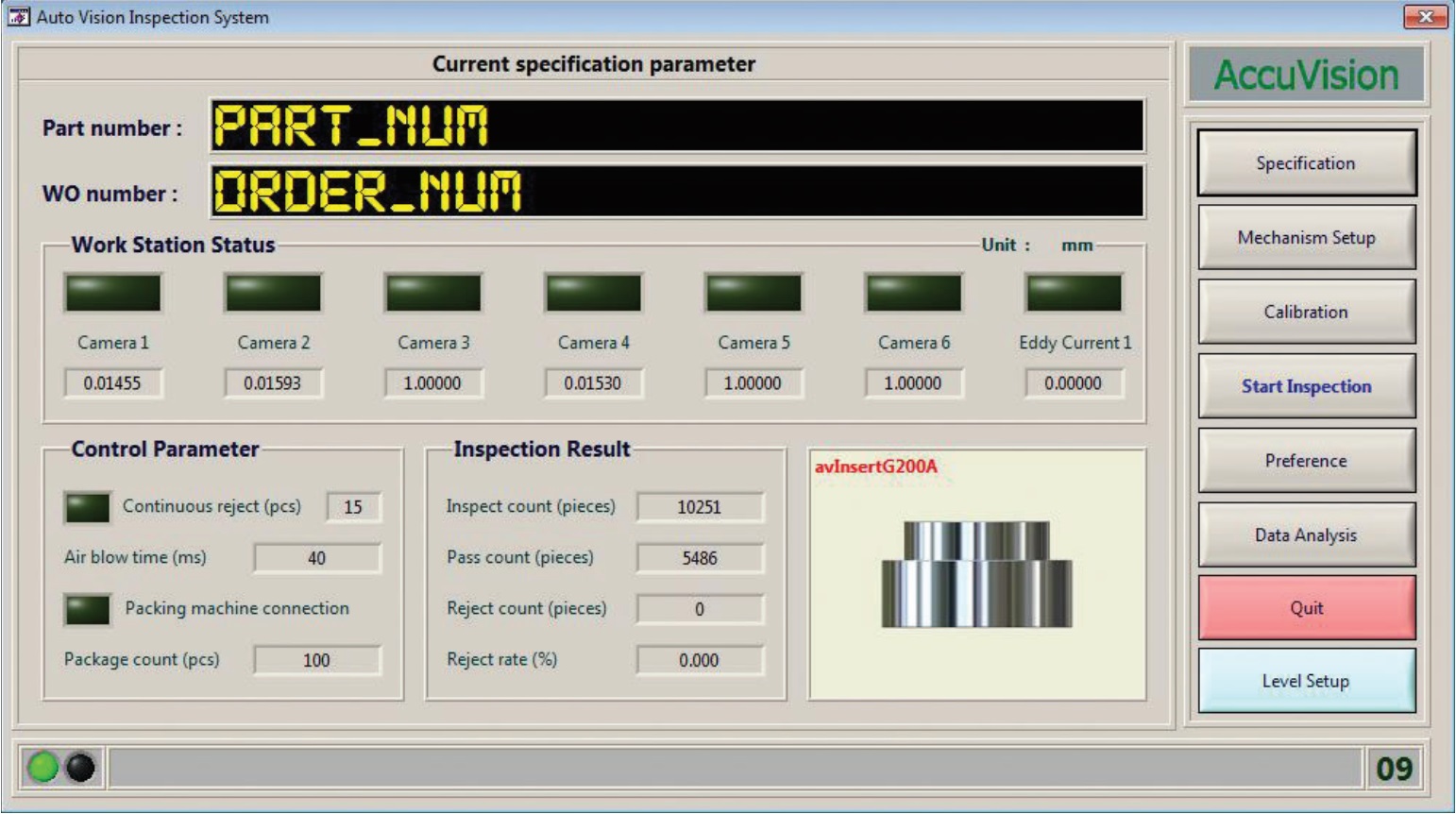

INSPECTION SOFTWARE

User friendly GUI graphic user interface

Add-on features: Statistatics inspection data analysis, defective analysis, SPC chart, report output data, support remote service, CAI computer aids instruction, etc

Inspection software should be designed according to customer requirements in detail.