Overview

Impact resistance is one of the most critical material characteristics for engineers to consider when designing a metal or plastic component. The ability of a material to withstand repeated brunt schock forces is especially important for any sort of moving part used inside a machine. Impact testing is especially prevalent in the automotive and aerospace industries where product reliability and lifespan.

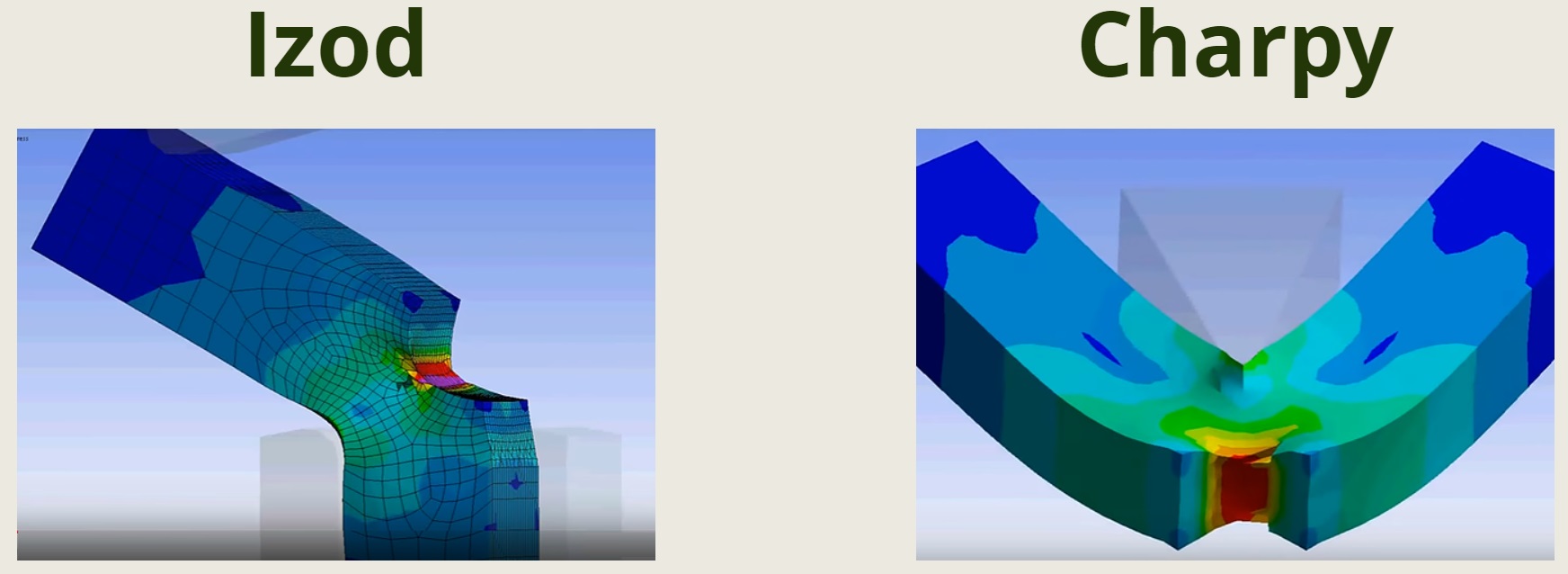

ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy absorbed by the notched specimen when impacted by a swinging pendulum. A typical Charpy test requires the notched metal specimen to rest on supports at each end (in a horizontal way) while coming in contact with vertical anvils adjacent to the supports. The specimen is then struck opposite the anvils at its centerline by a striker that is attached to a swinging pendulum (hammer).

In order to measure the toughness of a material using a Charpy impact test, it is necessary to obtain specimens from the material or product of interest. Normally, specimens are 55 mm long with a 10 x 10 mm section and a central V-notch of 2 or 3.3 mm or a U-type of 5 mm. The standard also allows reduced section specimens 10 x 7.5 or 10 x 5 and in this case special thicknesses to be interposed between the supports and the specimen to assure the perfect striker stroke axiality have to be provided.

CHARPY & IZOD IMPACT TESTER - INTRODUCTION VIDEO 1

Impact is a particularly safe instrument with solutions exceeding standard requirements, for example the metal bar that mechanically stands between the armed pendulum rod and the area where the operator manually loads the specimen. The fully interlocked protection guard is also available with two access doors for easy retrieval of post-test specimen parts. Transparent lexan panels permit the operator to view the impact test. The machine includes a motorized return of the hammer to the release point to eliminate any operator lifting of the hammer preventing injury.

ASTM E23 details the requirements for impact testing of Charpy specimens. Additionally, the application we were asked to perform required NIST (National Institute of Standards and Technology) certified results. Since NIST requires that the specimens be cooled to -40° C and then tested at that temperature, it is necessary to have a cooling bath for high series energy breaks. As soon the test is done, it is necessary to send NIST our documentation that includes the impact energies of each specimen along with the broken specimens for certification review. We can expect either certification (pass) or a failure report that includes suggestions for modifications to meet the next NIST certification attempt. These procedures can be submitted to the Galdabini Service Center that will handle the entire procedure. BCR certified specimens are also available for measuring instrument accuracy checking.

Charpy pendulums are available in different sizes of 150, 300, 450 or 750 Joule and can be supplied complete with plinth in pre-compressed material to avoid customer foundation works.

GALDABINI offers a complete range of metal - pendulum impact tester with a nominal range of 150 / 300 / 450 / 600 / 750. The machines are equipped with motorized hammer lift and electronic control panel. The equipment can be used for Charpy and Izod tests according ISO148 or ASTM standard.

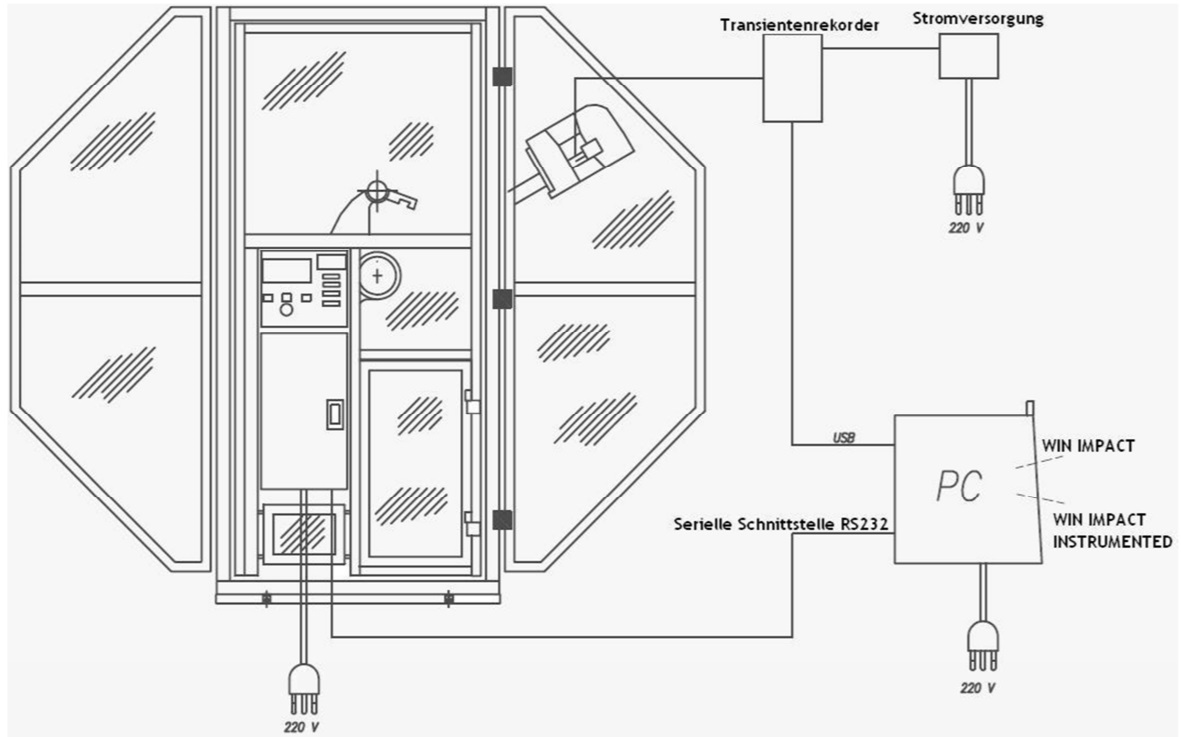

This modern and state of the art designed impact testers are controlled by a microcontroller which ensures al safety rules (interlock of door, catching the hammer after impact test). The controller will be operated by the user by integrated, comfortable touch panel. This panel also shows the consumption of energy after the test. At the integrated data connection this result can be exported in easy way (ASCII-signs at RS232 port. After breaking the specimen the hammer will automatically rise to the start position and insures with this a continuously comfortable work.

PENDULUM IMPACT TESTER - INTRODUCTION VIDEO 2

Features

- Rigged machine bodies designed using the FEM finite element method

- Protective housing with electrically locked security door

- Suitable for notch impact and impact bending tests on standard specimens or samples with reduced cross-section (abutment support)

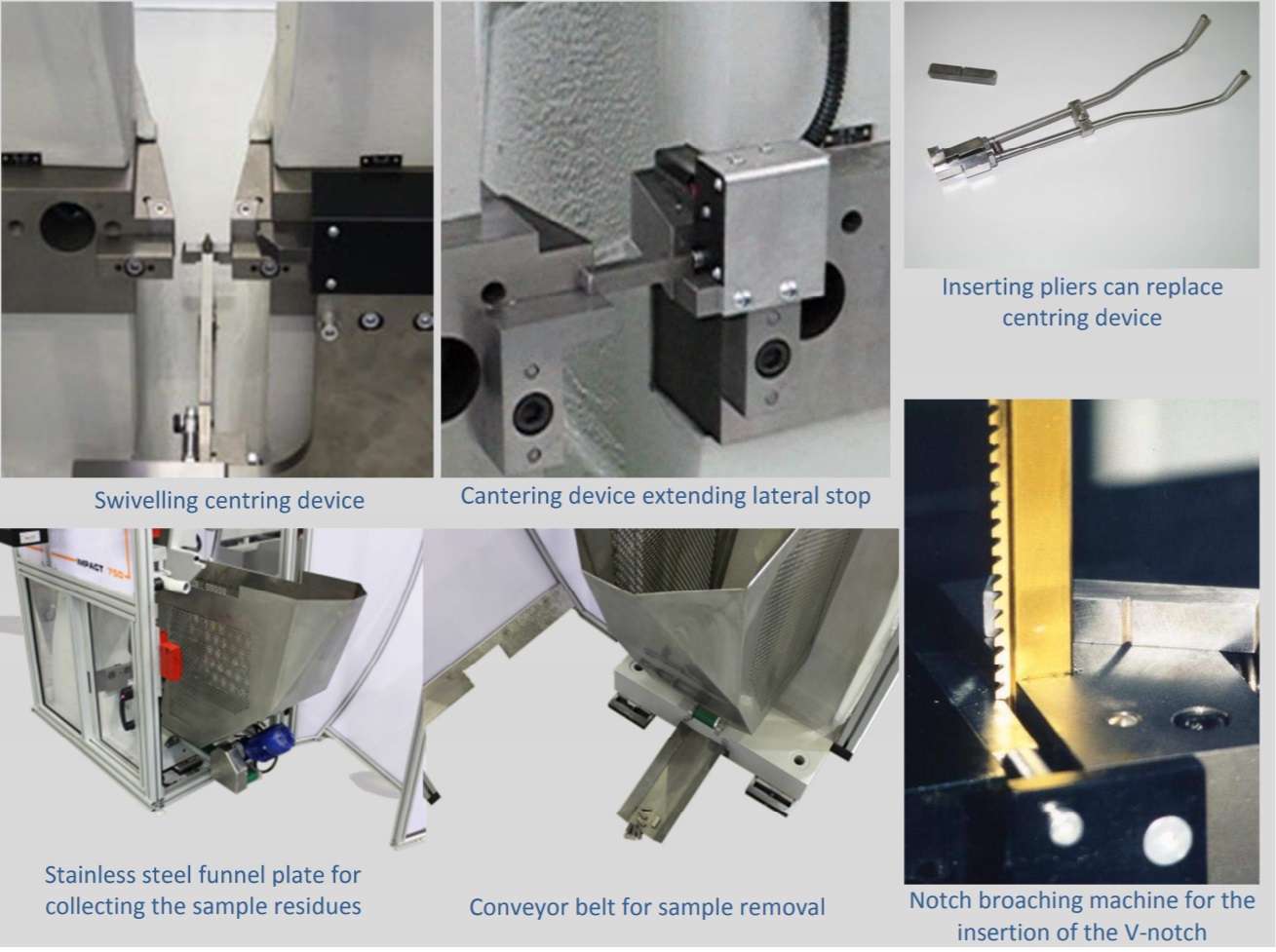

- Optional sample centring device: Sample can be inserted without centring pliers

- Futuristic design and advanced technology

- Optionally automated available (unmanned testing)

- Manufactured by ISO 9001 certified compan

- Unbeatable quality-price ratio

- State-of-the-art technology with touch screen control panel + test memory for 99 tests

Advantages

- Electronic control panel for easy setting of: Test method (Charpy / Izod), used standard (EN, ASTM, JIS ...), nominal energy (change of weight masses), potential / consumed energy, sample data, test temperature, date + time

- The test results can be read out via the USB/LAN interface for further processing in the optional WIN-IMPACT software, evaluated, printed and archived

- The exact angular position of the trigger angle and the evaluation of the impact energy consumed are determined by means of a highresolution incremental rotary encoder. The high resolution ensures the high-precision evaluation of the absorbed energy

- The operator can easily activate the automatic hammer lift (standard setting) in the operator menu. The hammer lift uses the residual energy available after the previous attempt to quickly raise the pendulum again by closing an electro-mechanical clutch at right time

- The automatic pendulum hammer lift ensures that the pendulum hammer is ready for the next test in a few seconds

- The pendulum hammer can be manually moved to any position for changing the weight masses, the impact fin or for calibration

- The pendulum hammer can be equipped with conventional impact fins (Charpy, Izod, impact pulling devices) or other tools that can be changed quickly and easily

- The machine was specially designed for absolutely hazard-free use. Among other things, safety devices are used here that have not been implemented by any other supplier to date (swivel safety rod). Due to the protective housing and the electrical locking of the safety door, simple and fast operation from the outside is possible

Option

- 2 types of centring devices: A.) swivelling in from below B.) with extending lateral stop

- Loading tongs for handling cooled samples, with centring function (centring device may not be required)

- Deep cooling cryostat: Bath for notched bar impact bending samples down to - 90° C (special brochure)

- Stainless steel funnel plates with conveyor belt: Broken samples are directed funnel-like onto the conveyor belt (recommended if the lateral expansion of the samples must be measured / the samples are sorted

- Side parts protective housing hinged and locked one side / both sides

- Application of the hammer fin for instrumented notched bar impact tests with special electronics / software

- Notch broaching machine for the rational insertion of the notch into a prefabricated sample 55 x 10 x 10 mm

Specification

Potential Energy (Joule) | 150 | 300 | 450 | 600 | 750 | Impact speed 5,5 m / second |

Power supply | 230 V / 50 Hz / 110 V / 60 Hz – other clamping on request | |||||

Power consumption Watt | 450 | 450 | 650 | 1000 | 1300 | |

Machine weight ca. kg | 670 | 670 | 670 | 1.530 | 1.530 | |

Weight (min.) kg | > 1.200 | > 1.200 | > 1.200 | > 2.400 | > 2.400 | Flatness: 0,5 mm / 1.000 mm in both directions |

Supported Standards | EN ISO-148, ISO-R/442 ASTM E4, ASTM E23-00a; JIS and other | |||||

Time motorized hammer lifting | < 9 seconds | |||||

Operating temperature | Temperature / Air humidity + 10 – 40 °C / 10 – 90 % | |||||

Cooled samples | According required (down to 196° C possible) | |||||

Sample throughput | approx. every 15 seconds = approx. 240 samples per hour | |||||

Dimensions: | ||||||

Height mm | 2000 | 2100 | ||||

Width mm | 2360 | 2450 | ||||

Depths mm | 960 / 1.100 (450 J) | 1200 | ||||