Handheld XRF for Positive material identification

14:23 - 04/03/2021

X-Ray fluorescence handheld spectrometer is an ideal tool for PMI because of excellent precision for metals in wide concentration range (from ppm to 100%), fast results getting (several seconds) and nondestructive testing

Analysis of Aluminum ADC12, ADC6 According to JIS H 5302 Standard

Main Magnesium Alloys used in Industrial Production

What is X-Ray Diffraction (XRD)

ElvaX ProSpector for Regulatory Compliance

The TrueX handheld alloy analyzer integrates the latest scientific innovations of LANScientific and is a powerful tool for metal material identification in the production process. It has the advantages of fast, high precision, portability, and other advantages. It can carry out on-site detection and rapid classification of large amounts of metal waste, providing users with rapid, efficient and accurate data information.

Advantages of TrueX 800/860:

- The product's built-in brand database contains 380 kinds of alloy brands, which can solve the conversion problem of different countries' brands in special industry applications. At the same time, users can customize the expansion of alloy brand library, can simultaneously analyze more than 600 kinds of alloy, alloy materials more than 10,000 kinds.

- New net strength fitting method, super-FP algorithm enables users to accurately analyze metal material and element content without switching modes.

- The whole testing process has no damage to the product, and the measurement can be carried out under various extreme environmental conditions such as high and low temperature, dust, dark and damp.

- Professional management analysis software, can set up security password, output customized, personalized and with the company LOGO analysis report.

- One-button operation, more convenient; The instrument is smaller and lighter, convenient for users to carry, and remote control of the instrument can be easily realized.

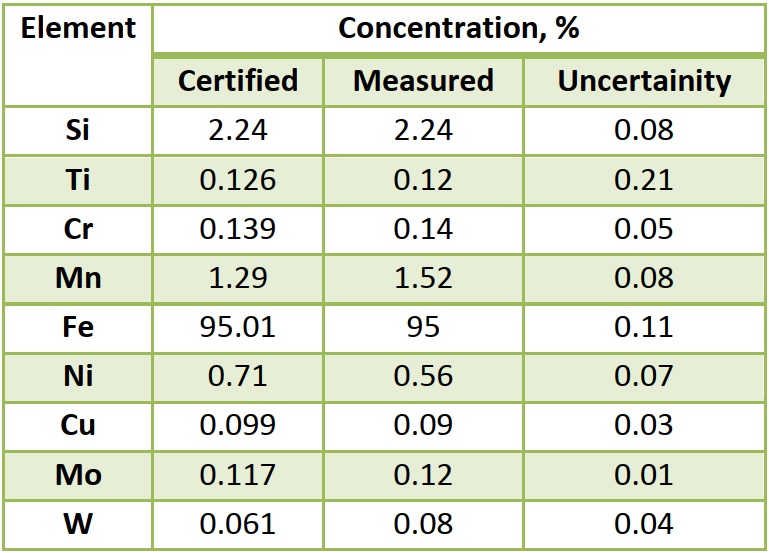

Compare to alloy. Displaying both measured and certified concentrations of a specific alloy ID:

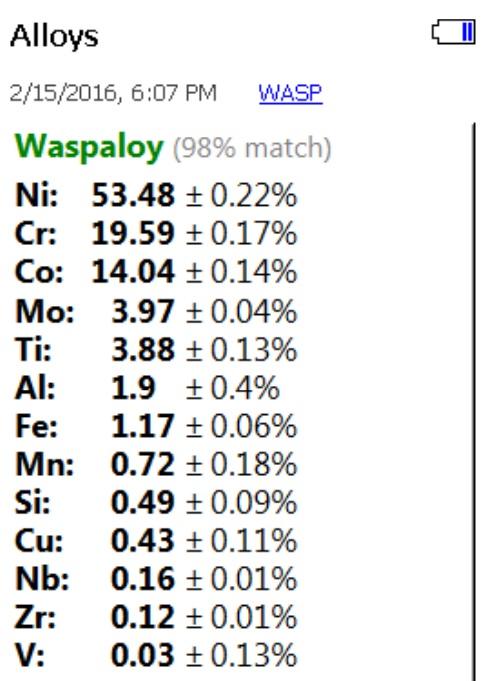

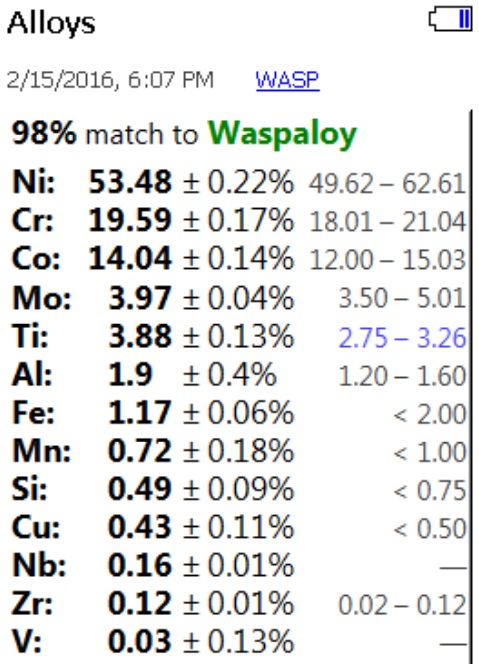

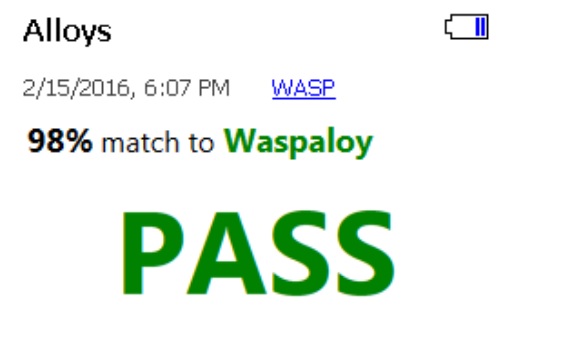

Pass/Fail. It is a useful mode for grading a specific alloy ID. Displaying “Pass” message when measured alloy fully complies alloy grade what you want, and “Fail” in other case.

Detailed specification of TrueX 800/860:

Alloy analysis requires minimal sample preparation. The most samples can be measured directly, but if any surface impurity or rust is presented, then analyzed surface must be polished.

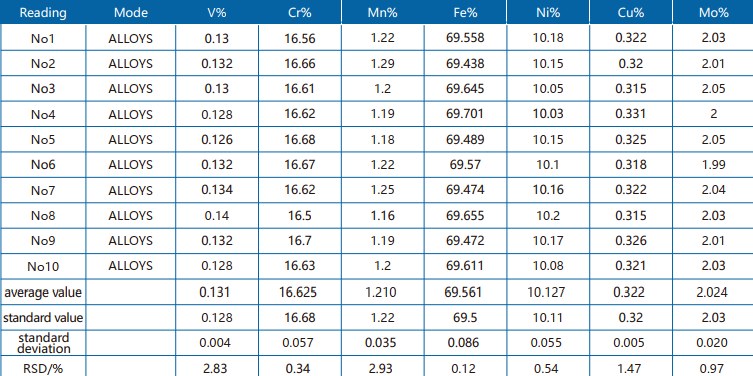

Alloy analysis 10 times:

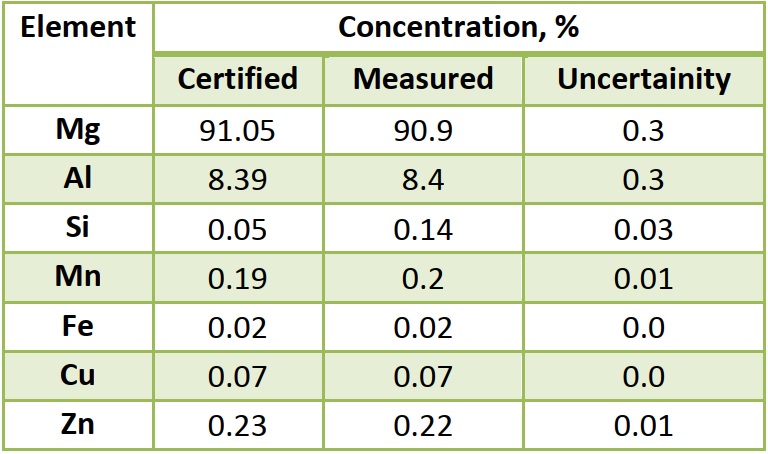

Magnesium alloy AZ80A (UNS M11800):

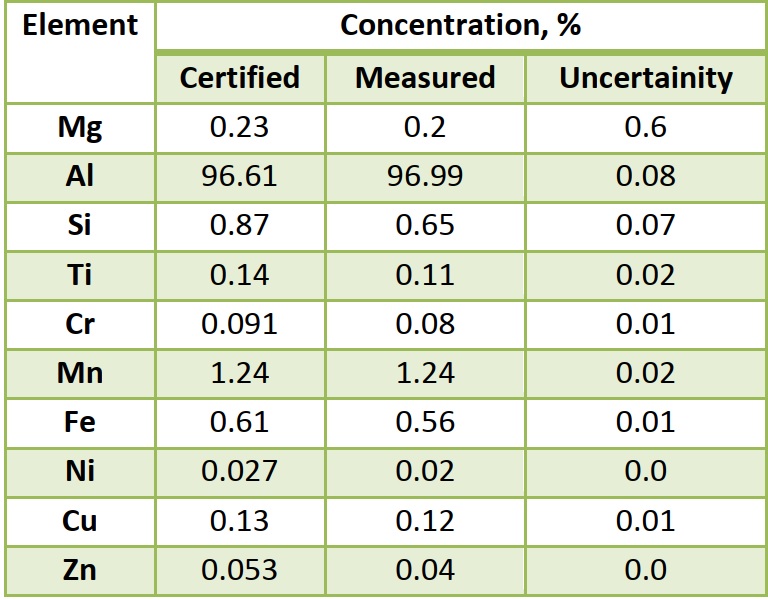

Aluminum alloy grade 3030 (UNS A93030)

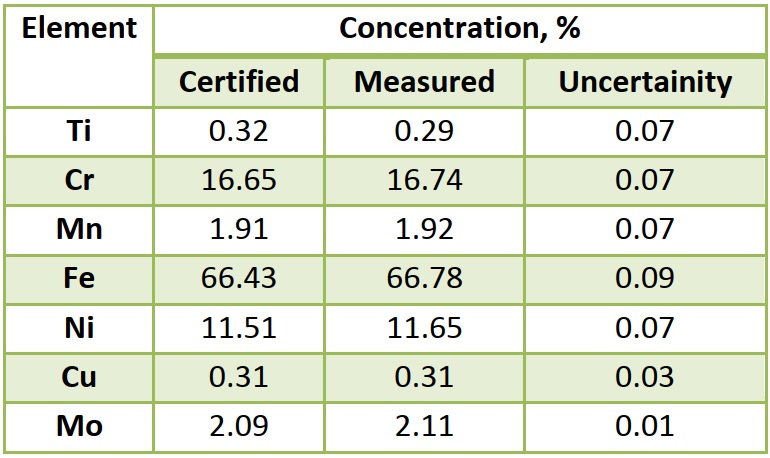

Stainless steel grade 316 (UNS S31600)

Low alloy steel AISI 9260

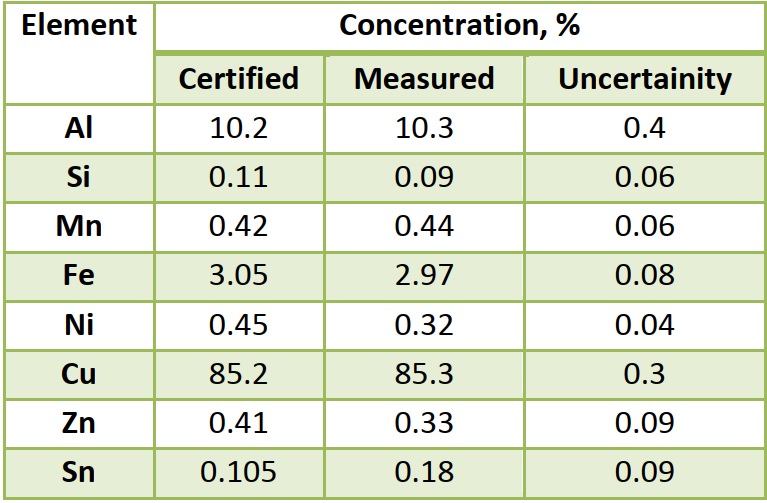

Bronze grade UNS C61900

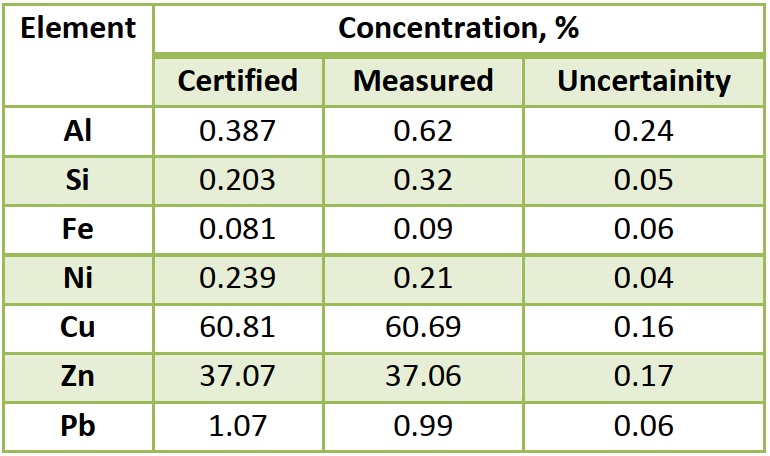

Brass grade UNS C37000

Another important parameter of XRF device is the repeatability of the analysis. The SS316 was measured 10 times over a period of time. An average, standard deviation (Std Dev) and relative standard deviation (RSD) for Fe, Cr, Ni, Mo content was calculated from this data:

| No | Fe, % | Cr, % | Ni, % | Mo, % |

| 1 | 66,81 | 16,76 | 11,59 | 2,13 |

| 2 | 66,81 | 16,78 | 11,57 | 2,13 |

| 3 | 66,82 | 16,77 | 11,58 | 2,14 |

| 4 | 66,85 | 16,77 | 11,54 | 2,13 |

| 5 | 66,84 | 16,77 | 11,57 | 2,13 |

| 6 | 66,81 | 16,76 | 11,57 | 2,14 |

| 7 | 66,82 | 16,77 | 11,59 | 2,14 |

| 8 | 66,85 | 16,72 | 11,6 | 2,13 |

| 9 | 66,84 | 16,75 | 11,58 | 2,14 |

| 10 | 66,8 | 16,76 | 11,61 | 2,13 |

| Average | 66,825 | 16,761 | 11,58 | 2,134 |

| Std Dev | 0,016 | 0,011 | 0,014 | 0,005 |

| % RSD | 0,024 | 0,066 | 0,121 | 0,234 |

Video:

Analysis of SS304:

Analysis of SS316:

Analysis of Aluminum AA6061: