Analysis of Zinc Alloy Composition According to ASTM B6 and ASTM B240 Standards

14:46 - 20/05/2025

In the hardware industry, zinc alloys play a crucial role. Thanks to their outstanding properties, zinc alloys are increasingly applied across various fields, contributing to the perfection of mechanical components

Main Magnesium Alloys used in Industrial Production

What is X-Ray Diffraction (XRD)

Handheld XRF for Positive material identification

ElvaX ProSpector for Regulatory Compliance

In the hardware industry, zinc alloys play a crucial role. Thanks to their outstanding properties, zinc alloys are increasingly applied across various fields, contributing to the perfection of mechanical components.

1. Scope of Application

Type | Standards | Features |

Pure Zn | ASTM B6 | Zn ≥ 99.95%, Low Impurities |

Zn-Al (ZAMAK 3) | ASTM B240 | Al 3.9-4.3%, Easy to Cast, Widely Used |

Zn-Al-Mg-Cu | According to Actual Composition | Improved alloy, increased strength, precision casting |

These alloys are widely used in the automotive, electronics, construction, and packaging industries.

This standard specifies the testing methods for determining the chemical composition of zinc and zinc alloys, including elements such as:

Zinc (Zn)

Aluminum (Al)

Magnesium (Mg)

Copper (Cu)

Iron (Fe)

Lead (Pb)

Cadmium (Cd)

Tin (Sn)

Rare earth elements and other impurities

2. Analytical Methods

To meet the needs of analyzing the composition of zinc and its alloys, three main technical groups are commonly used:

• Optical Emission Spectroscopy (OES)

Principle: An electric arc excites the solid sample through an optical system (lens, diffraction grating, etc.), generating characteristic emission spectra of each element.

Advantages: Fast analysis (20–40 seconds), simultaneous detection of multiple elements (Zn, Al, Pb, Fe, Cu, Sn).

Disadvantages: Requires grinding and surface cleaning prior to measurement.

• X-ray Fluorescence (XRF)

Principle: X-rays excite electrons, causing the sample to emit characteristic photons, which are then analyzed by a detector.

Advantages: Non-destructive, can measure directly on parts or coils, portable.

Disadvantages: Low sensitivity to light elements (Al, Mg), requires calibration standards.

Measurement Time: ~60 seconds per point

• Wet Chemistry & Atomic Absorption Spectroscopy (AAS)

Principle: The sample is dissolved in acid, and light absorption by atoms is measured using a flame (Flame AAS) or graphite furnace (GFAAS).

Advantages:

Very high sensitivity for trace elements (Cd, Pb, Mg, Mn at ppb levels)

Lower equipment cost compared to OES

Disadvantages:

Time-consuming sample preparation (dissolving, filtering, diluting)

Generates chemical waste

Measurement Time: 5–15 minutes per complete sample

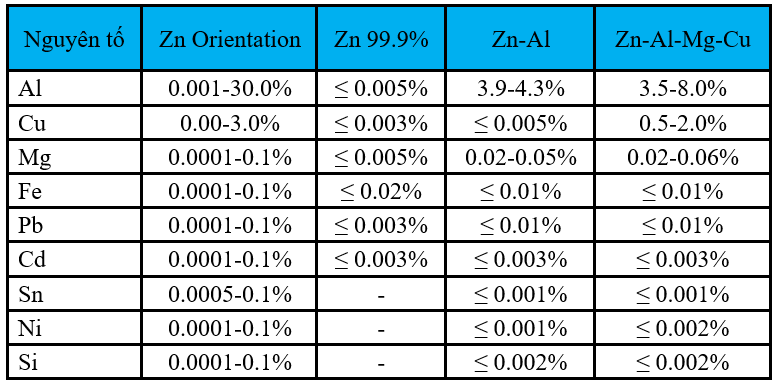

3. Applications of Material Groups

| Material Group | Main Applications |

|---|---|

| Zn 99.9% | Hot-dip galvanizing to protect steel, Zn-MnO₂ battery manufacturing, zinc compound production, base alloy, and electroplating |

| Zn-Al (ZAMAK) | Precision die casting of small parts: electrical housings, furniture accessories, motorbike components |

| Zn-Al-Mg-Cu | Die casting of light load-bearing parts such as hinges, handles, electronic frames, automotive parts, and outdoor corrosion-resistant coatings |

4. Elemental Composition Tables According to Standards

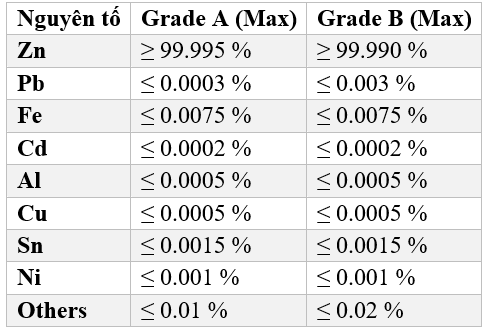

ASTM B6 – Pure Zinc (Zn)

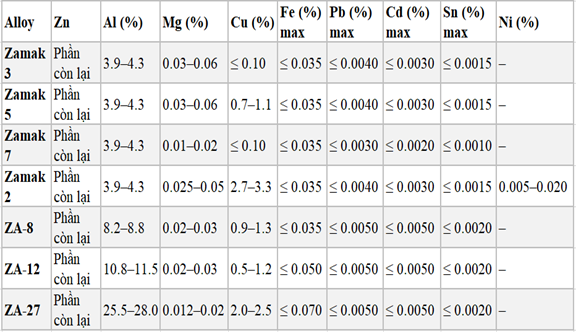

ASTM B240 – Zn–Al Alloys (Ingot)

5. Notes on Standard Application

ASTM B6 and ASTM B240 only define composition limits and ingot form requirements for pure zinc and Zn–Al alloys. These standards do not include detailed analysis methods or accuracy/tolerance specifications.

To perform accurate measurements, the following analytical method standards should be applied:

ASTM E634 for Spark/OES optical emission spectroscopy

ASTM D7343 for X-ray fluorescence (XRF) analysis

ASTM E536 for wet chemical analysis and atomic absorption spectroscopy (AAS)

Combining B6/B240 with analytical method standards ensures:

Clear specifications: composition limits from B6/B240

Reliable results: precision, reproducibility, and limit of detection (LOD) from analytical standards

6. Analytical Equipment

• Benchtop OES Spectrometers: S1 MiniLab 150 / S3 MiniLab 300 (GNR – Italy)

Application: Fast and accurate analysis of Zn, Al, Cu, Fe, Ni, Sn base alloys

Advantages:

Compact design, user-friendly

Multi-element analysis with high resolution

Low argon gas consumption

Below is a list of elements that the S1 MiniLab 150 or S3 MiniLab 300 can analyze in zinc alloys:

• Handheld XRF Analyzer: TrueX 800/860

Application: Rapid analysis of Zn, Al, Cu, Mg-based alloys

Advantages:

Compact and portable

Quick, non-destructive results

Ideal for on-site material sorting and quick inspection of incoming materials

If you need consultation on choosing the most accurate equipment for zinc alloy composition analysis, please feel free to contact us!