Guide to choosing DELOLUX pilot Sxi or SxT controller for DELOLUX 50 spot UV irradiators

14:22 - 18/05/2021

Applications that require UV adhesive and UV curing are very common in the industry. Depending on different purposes, choosing the appropriate type of glue and UV lamp is necessary. For small parts such as in electronic components, the bonding area is only a few millimeters, the choice of a spot-type<

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Applications that require UV adhesive and UV curing are very common in the industry. Depending on different purposes, choosing the appropriate type of glue and UV lamp is necessary. For small parts such as in electronic components, the bonding area is only a few millimeters, the choice of a spot-type glue curing lamp is the most appropriate.

| |

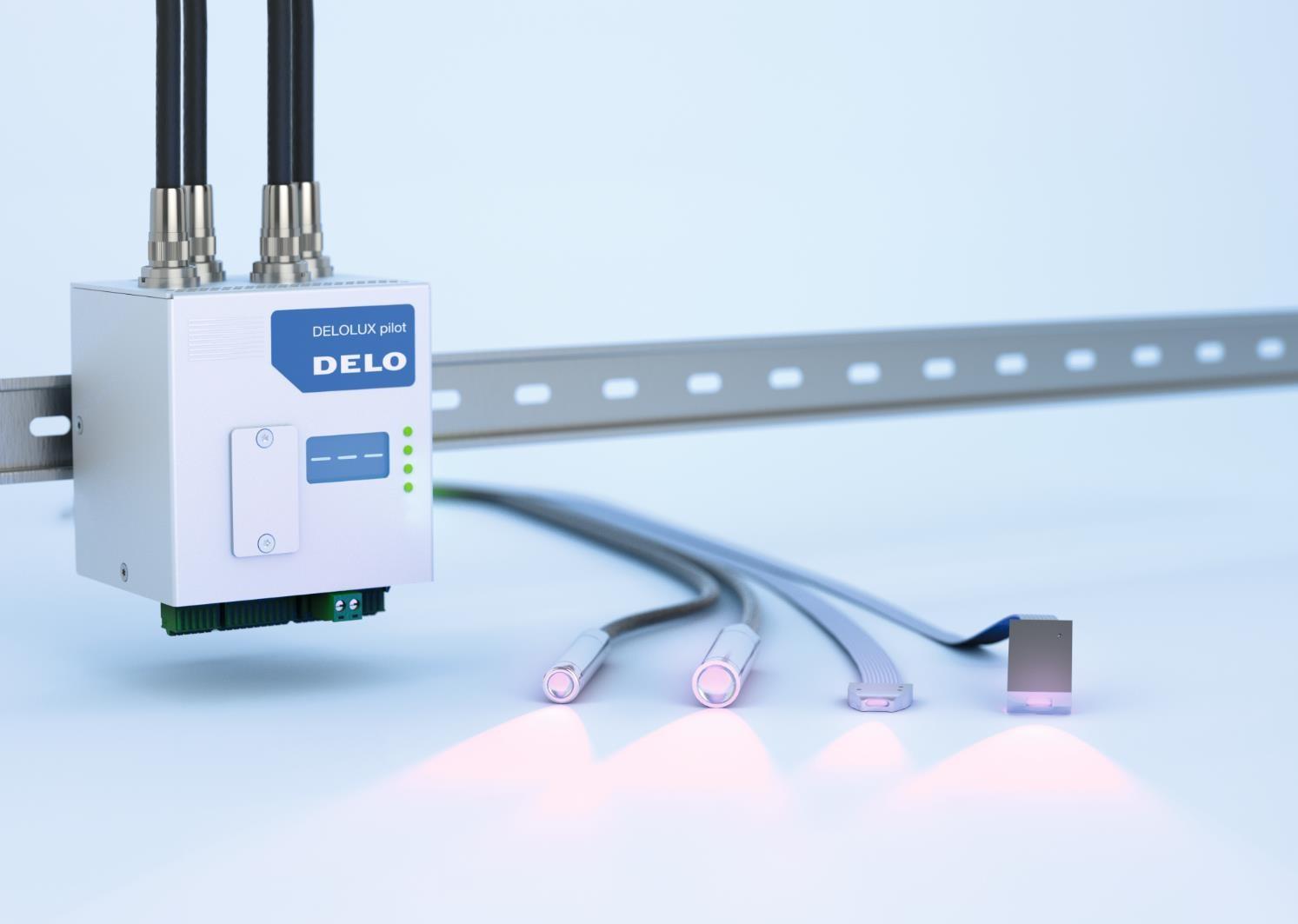

Example of UV glue curing application with DELOLUX50/502 lamp | |

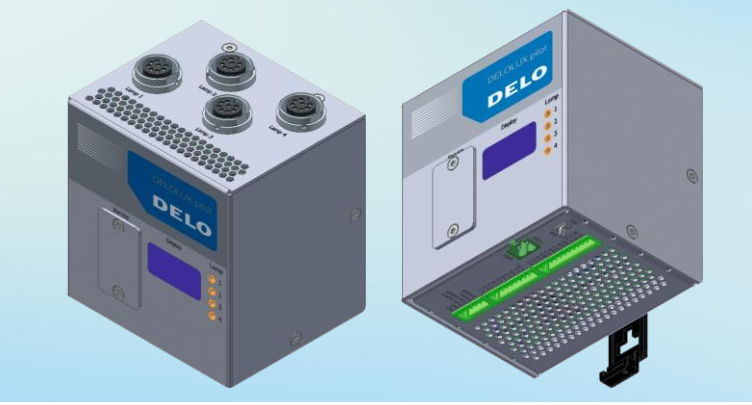

DELOLUX S4i Controller

DELOLUX 50 spot lamp is a type of UV lamp used to irradiate small or very small areas of glue such as onboard chips, camera modules, mini speakers on smartphones, etc.

These lights are controlled by DELOLUX pilots S4i and S4T. These are two new models improved by DELO, with higher irradiation intensity power and more compact size.

DELOLUX pilot S4i (i=integrated) is used for DELOLUX 50 lamp heads and is specialized for integration with PLC system, control for automatic production lines.

- The model has dimensions (WxDxH mm): 94 mm × 104 mm × 86 mm;

- Connect up to 4 DELOLUX 50/502 lamp heads;

|  |

DELOLUX S4i Controller | DELOLUX S4T Controller |

DELOLUX S4T Controller

DELOLUX pilot S4T (T=Touch) is a fully designed model for an individual UV irradiator.

Model is controlled manually by touch screen without PLC;

However, this model also allows connecting to the PLC if you want to switch to automatic mode.

- Dimensions: 235 mm × 202 mm × 152 mm.

- Connect up to 4 DELOLUX 50/502 lamp heads;

Compared to its predecessor, this version of S4 gives 2.5 times more power (from 60W to 150W). This helps the DELOLUX 50 lamps give higher irradiance, speed up the curing of the glue, and shorten the production time.

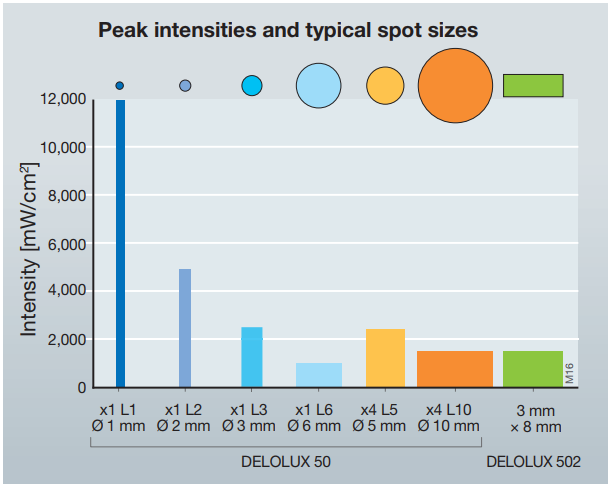

Overview of the types of DELOLUX 50 lamp heads

Types of DELOLUX 50 /502 Lamp Heads

There are basically 2 types, DELOLUX 50 and DELOLUX 502.

These LUX 50 lamp heads can all be connected from 1~4 units running at the same time to the DELOLUX pilot Sxi/SxT controller (x =1~4 is the number of lamp heads that can be connected).

The LUX 50 lamp head has a round shape with different lens sizes, which will give different irradiation areas. Details of these lenses are given in the table below.

In the LUX 50 series, it is also divided into 2 more types: LUX 50x1 which has only 1 LED bulb / 1 lamp head, and LUX 50x4 with 4 LED bulbs / 1 lamp head.

For the LUX 502 series, the lamp head is flat, with 2 fixed LEDs / 1 lamp head. The irradiation area is also fixed at 3 x 8 mm.

Specifications of different lenses for DELOLUX 50 and 502 lamp heads

Lamp head | Lens | Irradiation area | Working Distance (mm) | Irradiation intensity (mW/cm 2 ) |

DELOLUX 50x1 | L1 | Ø 0.6 ~ 1.1 mm | 3~5 | 12000 |

L2 | Ø 1.1 ~ 2.0 mm | 6~14 | 6000 | |

L3 | Ø 2.0 ~ 3.2 mm | 8~14 | 2500 | |

L6 | Ø 3.2 ~ 6.0 mm | 10~30 | 1000 | |

DELOLUX 50x4 | L5 | Ø 5.0 mm | 7~8 | 2500 |

L10 | Ø 10.0 mm | 9~15 | 1500 | |

DELOLUX 502 | - | 3 mm x 8 mm | 5~8 | 1500 |

From this table, it is easy to choose the right lens for the type of lamp and the specific requirements of each application. Adjust the distance of the lamps to the glued surface in accordance with the desired irradiation intensity.

The maximum irradiance intensity is proportional to the characteristic irradiation area of different lenses

Normally, for DELO's UV glue lines, the maximum intensity irradiation only at 700 mW/cm 2 is needed, so the irradiation distance can be customized quite comfortably, mainly needing to pay attention to the irradiation area for lamps. UV light covers the entire application area.

By using the DELOLUXcontrol irradiance meter, it is easy to control the UV intensity, align the irradiation distance to the sample as well as the power set on the DELOLUX Sxi/ SxT controller.

DELOLUXcontrol UV irradiation intensity meter

Contact HUST VN for specific advice on UV glue curing equipment and how to choose a UV lamp for your application!

HUST VN is proud to be the exclusive distributor of DELO adhesive products, dispensing, glue curing equipment, and technology transfer from DELO in Vietnam!