GLUE FOR GLASS FURNITURE – CREATING NEW DESIGN TREND

15:26 - 29/06/2021

Glassware brings a sense of luxury and sophistication to living rooms, cafes, or public spaces.

Glue is used a lot to bond glass parts together. Adhesives DELO PHOTOBOND PHOTOBOND 4494 and GB368 are two common glue codes used in these applications.

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Glassware brings a sense of luxury and sophistication to living rooms, cafes, or public spaces.

Glue is used a lot to bond glass parts together. Adhesives DELO PHOTOBOND 4494 and PHOTOBOND GB368 are two common glue codes used in these applications.

Table glass design

Glue requirements in glass furniture designs:

- Good adhesion to surfaces: glass/glass, glass/metal, glass/plastic, etc.

- Good resistance to weather, humid and harsh environments, does not change color when exposed to high temperatures or sunlight;

- Glue must be colorless and transparent;

- Compression shear strengh of glass/glass > 17 MPa.

PHOTOBOND glue is a line of modified acrylate glue, 1 component, cured under ultraviolet light (UV) with extremely fast curing speed in only 15 ~ 30 s.

Using DELO glue will bring additional values beyond customer expectations:

General features of DELO PHOTOBOND glue:

- Quick curing in seconds when using UV lamp; - Suitable wavelength: 320 ~ 420 nm; all DELOLUX lamps are possible. - Colorless and transparent; - Anti-discoloration / yellowing under high-temperature conditions or exposed to sunshine; - Stable to harsh environments; - Tensile- equalizing. |

The main technical parameters of these 2 glue codes as below:

Specifications | DELO PHOTOBOND – One-component acrylate clear glass adhesive | ||

PHOTOBOND 4494 | PHOTOBOND GB368 | ||

Color | Colorless | Colorless | |

Viscosity (mPa.s) | 20000 | 5700 | |

Density (g/cm 3 ) | 1.0 | 1.0 | |

Suitable wavelength (nm) | 320~420nm | ||

Curing time (s) | 3~7 s | 15s | |

Glue surface after curing | Tacky | Hard touch | |

Compression shear strength (MPa)

| Glass/glass | 28 | 23 |

Glass/ Al | 25 | 23 | |

Glass/ PC | 17 | 7 | |

Glass/PMMA | 4 | - | |

PC/PC | 18 | 6 | |

PMMA / PMMA | 10 | 15 | |

Glass/ABS | - | 15 | |

Elongation at tear (%) | 160% | 17% | |

Storage time | 9 months (+18~ +25 o C) | 12 months (0~25 o C) | |

Type of UV lamp used: | ||

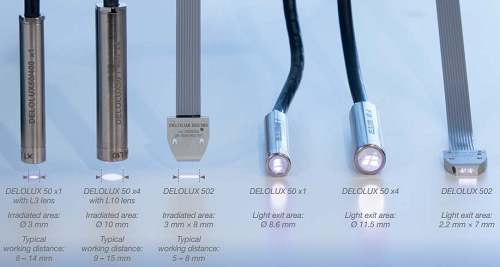

- DELOLUX 20/50/80 lamps are suitable for specific applications; - Fixed wavelength 365 nm or 400 nm are suitable; - Controlled by DELOLUX pilot AxT/S4T for a separate module or Axi/S4i for pairing and controlled by PLC PROFINET system; - Time life: >20,000 hours of continuous use; |

Refer to the following DELO lamps:

|  |  |

| DELOLUX 20 | DELOLUX 50x | DELOLUX 80 |

Surface treatment before applying glue: | |

- Use DELOTHEN cleaner for metal, plastic surfaces or DELOTHEN EP for glass surfaces. - 500ml spray bottle is available; | |

Dispensing methods: | |

Depending on the requirements of the application, customers can choose from the following ways to dispense the glue: | |

- Apply glue directly by hand. For simple applications, small joints, just need to apply glue by hand carefully with a 50ml glue flat bottle, easy to use. | |

- Using a precise dispensing pump system with large volume glue bottles (≥1000ml) DELOMAT 100, applications with designs that require high precision for small parts.

| |

Curing method: | |

- Depending on the application, select the appropriate type of UV lamp; - Set the time and intensity of UV irradiation. - Glue will be cured immediately after a few seconds of UV irradiation and will give strong adhesion after 3~5 minutes. | |

Feel free to contact us for advice and support in choosing the most suitable solution and glue for the application you are interested in. HUST Vietnam is proud of the exclusive distributor of adhesive products, glue release machines, UV glue drying lamps, and technology transfer from DELO in Vietnam. |