DISPENSER ROBOT 2-COMPONENT 3-AXIS XYZ GLUE DESKTOP

Outstanding features:

- Meets standards: CE certification

- Simple to operate, easy to install, and can be adjusted with the buttons on the front of the machine without using the controller.

- 3-axis XYZ moving robot with high precision < 0.01 mm. Meets a variety of complex surface shapes.

- The machine can download CAD files to change the glue application program.

- XYZ axis has 2 linear guide rails, increasing stability. X, Y, Z axises are equipped with imported bi-linear guide and precision stepper motor, running more stably than similar products, with higher load.

- The Z-axis brake motor, greatly increases equipment stability and movement precision, when the z-axis load is a maximum of 6kg, it will remain in the above position after power off.

- The machine can operate without PC control. There is an LED screen with a program list and soft control keys on the front of the robot. When you finish editing the program with the soft joystick, you can directly control the robot to work without the need for a hand controller.

- TIANHAO's specialized glue dispersion software is easy to program, has high accuracy, and improves product quality and productivity.

- USB port allows data transfer between PC and robot.

- Lightweight, easy to transport.

Application:

- Mixing ratio: 1:1 ~ 1:3, customizable.

- Tank: standard 4L, (optional 2L, 10L, 20L).

- Mixing method: static mixing.

- The machine provides high precision glue dispersion, fast speed, and can operate continuously for 24 hours.

- Suitable viscosity: < 10,000 mPa.s.

- Compatible fluids: 2-component epoxy adhesive, polyurethane with separate container.

- Compatible packaging types: 400 mL, 1L, 3.5L, 9L, 18L cans.

Specifications:

Model | TH-2004D-300 | TH-2004D-400 | TH-2004D-500 |

Working area X/Y/Z | 300 x 300 x 100mm | 400 x 400 x 100mm | 500 x 500 x 100mm |

Dimensions (WxDxH) mm | 500 x 580 x 610 | 600 x 680 x 610 | 700 x 780 x 610 |

Weight | 34kg | 39kg | 46kg |

Standard | CE Approved | ||

Maximum load XY/Z | 10 kg / 3 kg | ||

XY/Z speed | 800/350 mm/Axis | ||

Repeatability | ±0.01mm per axis | ||

Resolution | 0.005mm /Axis | ||

Memory storage | 9,999 programs / 4,000 points | ||

Data storage format | Flash Card/ USB | ||

Display screen | LCD display | ||

Software | Exclusive to TianHao (Available in English and Chinese) | ||

Drive system | Micro stepper motor | ||

Dynamic transmission | Belt guides accurately over time | ||

Program editing | Programming on PC (CAD files can be uploaded directly) Front panel (LCD&LED display) | ||

Front panel | Offset, run manual optimization & Select Offset program | ||

I/O Signals | 4 Inputs / 4 Outputs | ||

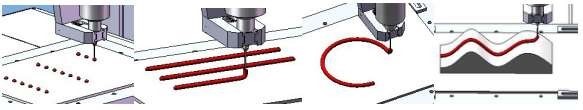

Types of glue application | 3D straight lines, circles, curves, continuous zigzag lines, running both XYZ and 3D simultaneously | ||

Number of glue distribution valves | 01 glue mixing valve. | ||

Inlet air pressure | 1-7bar (1bar =1.01972kg/cm² =14.5038psi) | ||

Output air pressure | 0.1bar-7bar | ||

Power supply | AC110V/220V Internal conversion | ||

Working temperature | 0 ~40℃ | ||

Working humidity | 20~90% (no dew) | ||

Increased benefits for customers:

- Increase production efficiency.

- Control the precision of the production process.

- Improve product quality.

- Reduce production costs, and reduce defective products.

- Reduce material waste.

Contact HUST Vietnam for more detailed advice on your products and applications!