2-COMPONENT GLUE ROBOT DUALCARTRIDGE 50mL 3 XYZ AXIS DESKTOP

Model: TH-2004D-300-206AB

Special features:

- Specialized for 50 ml 2-component glue bottles.

- Equipped with a quantitative glue control system using air pressure and time.

- The controller accurately controls the amount of glue pumped out, and has a vacuum mode to prevent the glue from dripping when the pump stops.

- Professional glue checking software, customized settings as required.

- PLC controller, Easy to program.

- Each axis has 2 linear guide rails, providing greater stability.

- Z-axis brake motor, greatly increases equipment stability and movement precision.

Application:

In industrial production, potting, sealant, casting, molding, gasket applications for small and medium-sized parts.

Compatible with 2-component epoxy, polyurethane (PUR) glue lines, 50mL double glue bottles with all viscosity ranges.

Specifications:

Model | TH-2004D-300 | TH-2004D-400 | TH-2004D-500 |

Working area X/Y/Z | 300 x 300 x 100mm | 400 x 400 x 100mm | 500 x 500 x 100mm |

Dimensions (WxDxH) mm | 500 x 580 x 610 | 600 x 680 x 610 | 700 x 780 x 610 |

Weight | 34kg | 39kg | 46kg |

Standard | CE Approved | ||

Maximum load XY/Z | 10 kg / 3 kg | ||

XY/Z speed | 800/350 mm/Axis | ||

Repeatability | ±0.01mm per axis | ||

Resolution | 0.005mm /Axis | ||

Memory storage | 9,999 programs / 4,000 points | ||

Data storage format | Flash Card/ USB | ||

Display screen | LCD display | ||

Software | Exclusive to TianHao (Available in English and Chinese) | ||

Drive system | Micro stepper motor | ||

Dynamic transmission | Belt guides accurately over time | ||

Program editing | Programming on PC (CAD files can be uploaded directly) Front panel (LCD&LED display) | ||

Front panel | Offset, run manual optimization & Select Offset program | ||

I/O Signals | 4 Inputs / 4 Outputs | ||

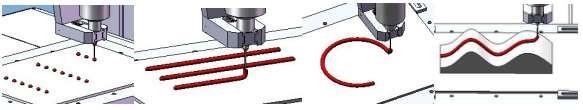

Types of glue application | 3D straight lines, circles, curves, continuous zigzag lines, running both XYZ and 3D simultaneously | ||

Number of delivery valves/cartridge clamps | Valve: 1, 2; cartridge clamp 1,2,3,4 (standard is 1 valve or 1 cartridge clamp) | ||

Inlet air pressure | 1-7bar (1bar =1.01972kg/cm² =14.5038psi) | ||

Output air pressure | 0.1bar-7bar | ||

Power supply | AC110V/220V Internal conversion | ||

Working temperature | 0 ~40℃ | ||

Working humidity | 20~90% (no dew) | ||

Increased benefits for customers:

- Increase production efficiency.

- Control the precision of the production process.

- Improve product quality.

- Reduce production costs, and reduce defective products.

- Reduce material waste.

Contact HUST Vietnam for more detailed advice on your products and applications!