DELO KATIOBOND 4594 adhesive – a perfect solution for PCBs - FR4 components bondings on automotive

10:32 - 04/06/2020

In the automobile manufacturing industry, people also use the form of PCBs-FR4 hybrid board - attach copper coil in the car air conditioning system. Due to space-limited, copper coils cannot be fixed mechanically. Therefore, the best solution is to use adhesive.

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Today, print circuit boards - flame retardant (PCBs-FR4) has been developed and applying to various industrial areas like electronic, automotive, aerospace, …

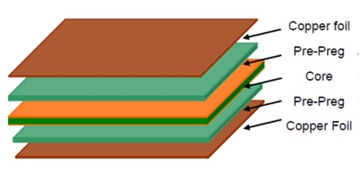

FR4 is a common material used to produce the print circuit board (PCB) in the industry, due to it has high strength, easy to manufacture, and very cheap. FR material has fire resistance thank the glass fibers reinforce to epoxy resin. When combination thin copper laminates cover FR material laminate, we will obtain a material to fabricate print circuit boards. For PCBs two laminates, the FR4 is placed between two copper laminates. For multilaminate PCBs, the FR4 PrePreg has been put between copper laminates and FR4 is the core one.

Structure of FR4 materials

Structure of FR4 materials

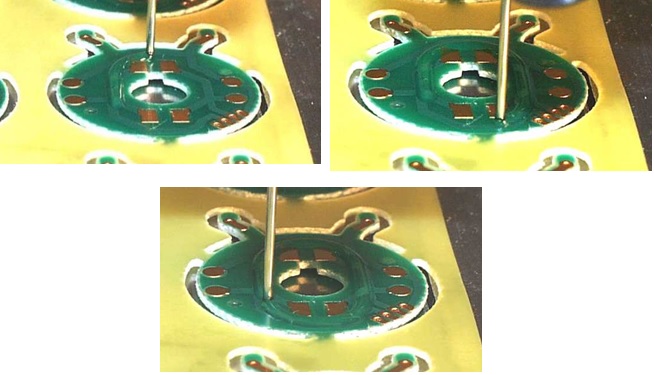

In the automobile manufacturing industry, people also use the form of PCBs-FR4 hybrid board - attach copper coil in the car air conditioning system. Due to space-limited, copper coils cannot be fixed mechanically. Therefore, the best solution is to use adhesive.

The car air conditioning system

However, some following difficult requests related to bonding copper coils by adhesive has to reach:

- Curing time is just seconds and heating does not allow (manufacture cycle is 5 s);

- Tensile strength above 100N when removing copper coils from circuit boards at 85 oC is reached;

- Copper coils have to completely bond into FR4-PCBs;

- Copper coils have to generate good magnetic;

- Meet the requirements that can be put into mass production lines PCBs-FR4 printed circuit boards in the automotive industry.

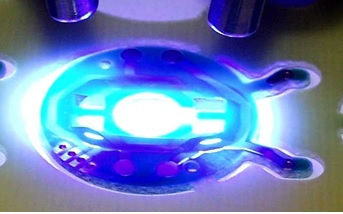

Understanding these essential domains, DELO has produced DELO KATIOBOND 4594, a UV (Ultraviolet) curing adhesive product kind specifically for the bonding of electronic components such as bond copper coils onto PCBs-FR4 in air conditioners for car or in many other industries.

FR4 - Print circuit boards

This adhesive not only satisfies the difficult requirements above but also brings many advantages for customers to use such as simplicity, space-saving in the production line, especially without any improvement in the production line to use glue.

Specifications about the strength test of DELO KATIOBOND 4594 adhesive has been published details on their website. Below show some especial specifications reach requirements to use adhesive when applying to bond copper coils onto PCB-FR4:

- The components have been bonded can be store in a long period, at high temperature: 125 oC in 1000h;

- Shock test resistance: : -65 °C/5 min, +150 °C/5 min, archived 100 cycles;

- Temperature follow cycles resistance: -65 °C/20 min, +150 °C/20 min, archived 100 cycles;

- Temperature – humidity test resistance: +85 °C, 85 % related humidity, archived 1000 h

- Tensile strength: at +85 oC, archived > 100N.

Bonding copper coils onto RCB-FR4 by use DELO KATIOBOND 4594 adhesive process:

- Prepare copper coils and circuit boards with clear surfaces;

- Dispensation adhesive by specialized equipment DELOMAT 100 in combination with automatic control system;

Activation adhesive with two UV lamps DELOLUX 04 (5 mm diameter, the irradiation time of 5 s);

- Put copper coils on glued parts;

- Irradiation to curing adhesive, fixing coils, irradiation time is 10 s;

- Transfer the completed components to the next stage;

- Adhesive will be cured completely within 24h;

- UV irradiation stage in the production line is extremely convenient, the whole object can be easily irradiate with the light direct wire of the DELOLUX 04 device even when the space is limited.

References:

https://vnpcb.com/fr4-vat-lieu-su-dung-rong-rai-trong-mach-in