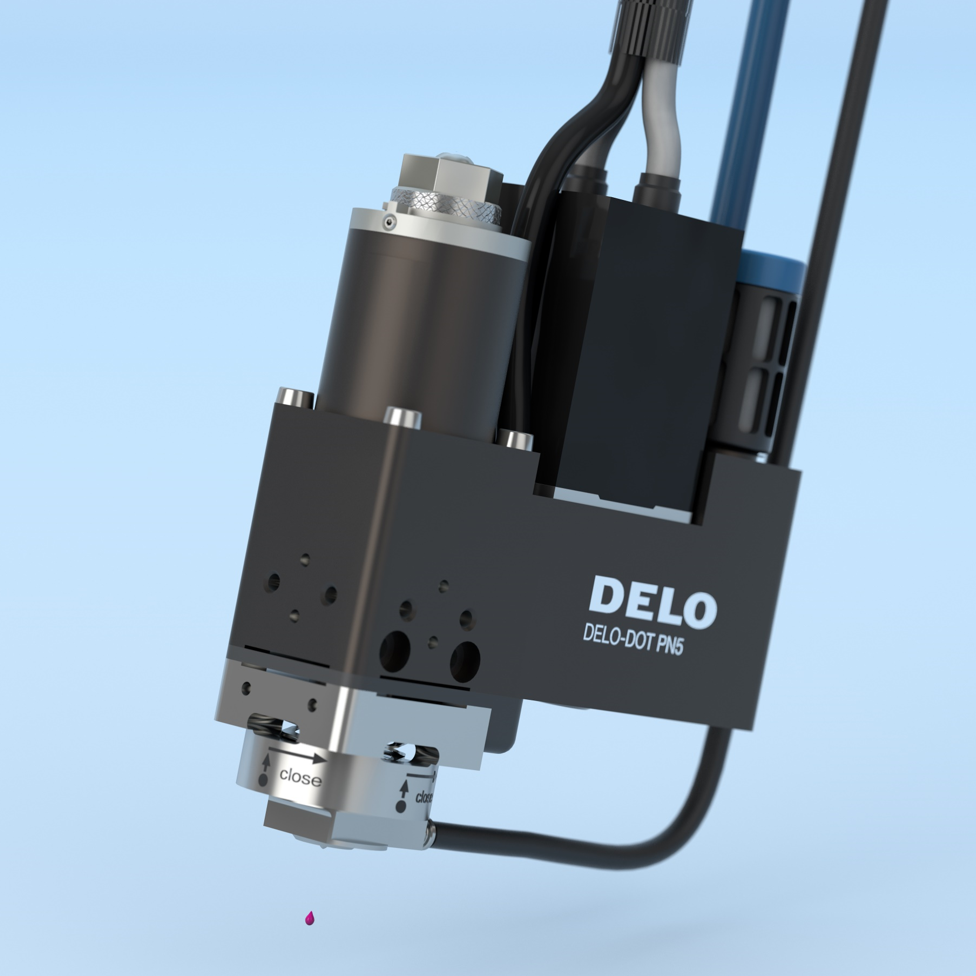

DELO-DOT PN5 non-contact glue release valve - high performance!

DELO-DOT PN5 is suitable for non-contact applications, preventing collisions between the release valve and other components. Adhesives that are highly viscous and difficult to drip, the valve can be dispensed accurately, and reliably.

The valve has nozzles of different diameters that can be easily replaced, as well as a flexibly adjustable piston stroke. This ensures that the application of the glue gives repeatability accuracy to the nanoliter scale.

The piston of the glue release valve is mainly made of ceramic and carbide. It is suitable for continuous use for a long time, even with complex materials. When the piston wears out at the end of its life, simply replace the injector and piston. No special disassembly tools are required as the conduit system, valve coupling can be easily removed by quick-release pins.

The actuator has a lifespan of more than a billion cycles. Compared to its predecessor, the new glue release valve can be cleaned easily and efficiently as fewer parts come into contact with the adhesive.

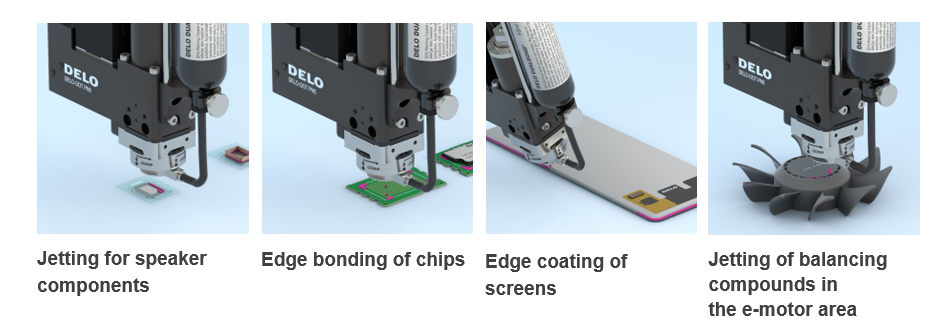

Popular applications:

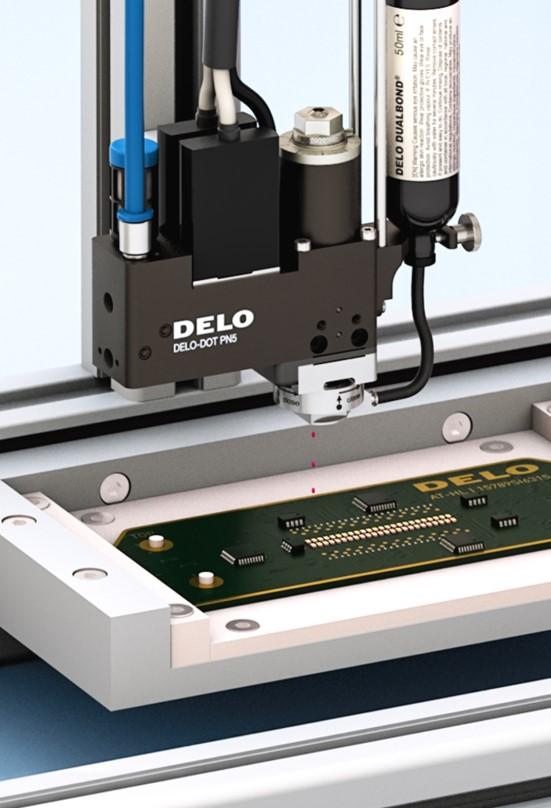

In electronic industrial production that requires high speed and accuracy, PN5 is capable of meeting those requirements.

For example: Smartcard production; RFID; mini-speaker, and smartphone,...

DELO-DOT PN5 is used in many applications electrical industry (DELO photo)

Specifications:

Driver | Pneumatic |

Maximum glue release frequency | 300 Hz (300 drops/s) |

Raw material viscosity | Up to 500,000 mPa.s |

Nozzle size | 0.05 / 0.1 / 0.2 / 0.3 mm |

Nozzle heating | Control up to 100 oC |

Valve life | 1 billion cycles |

Valve size | 86 mm × 28 mm × 99.5 mm |

Valve weight | 485g |

Salient features | Infinitely customizable, customizable glue bottle holder mounts in 4 90 ° positions on the nozzle |

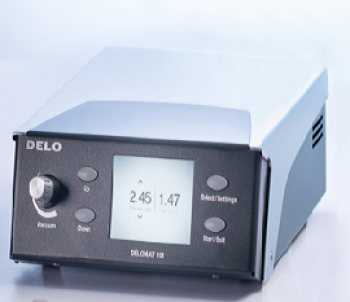

Corresponding controller | DELO-DRIVERBOX PN series

|

Reference video: https://youtu.be/QT9ni0jHUf8

Contact HUST Vietnam for more detailed information.

HUST Vietnam is proud to be the exclusive distributor of glue, dispensing equipment, UV curing lamps, and technology transfer from DELO in Vietnam!