DELO Adhesives for photonic integrated circuits (PIC)

15:36 - 27/09/2023

Photonic integrated circuits (PIC) play a major role in integrating optical functions like signal processing, data transfer, and sensing into electronic devices. A PIC is an advanced system on a chip in which multiple miniaturized optical components such as amplifiers, modulators, or filters are combined. Operating in the optical/IR ra

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Adhesives for photonic ICs (PIC)

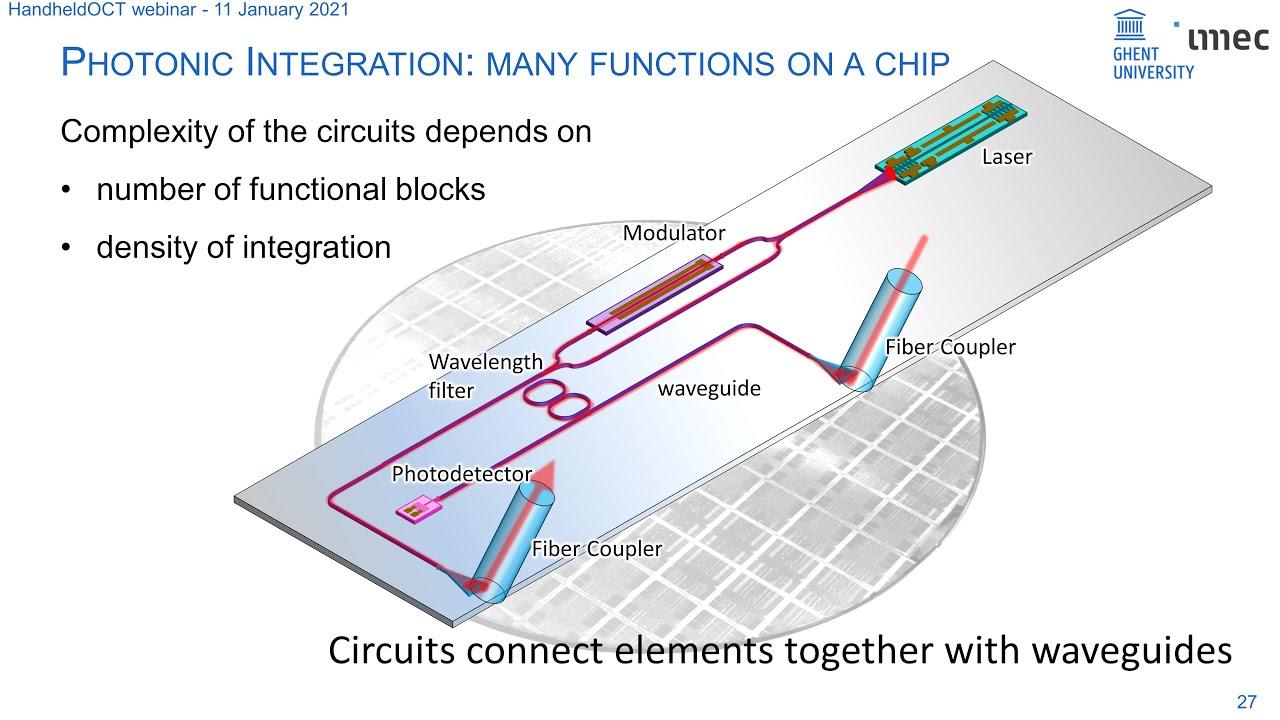

Photonic integrated circuits (PIC) play a major role for integrating optical functions like signal processing, data transfer, and sensing to electronic devices. A PIC is an advanced system on a chip in which multiple miniaturized optical components such as amplifiers, modulators or filters are combined. Operating in the optical/IR range of the EM spectrum (380 – 1650 nm), they allow very high bandwidth and data transfer at high speed.

Packaging and optical interconnecting on chip-level as well as on board-level is technically very challenging. Low coupling loss requires very precise active alignment capable adhesives. Post-processing like the assembly of electronic SMDs by typical reflow processes underlines the need for highly reliable materials.

Optical coupling

There are several approaches to couple a PIC with optical fibers. In general, single mode fibers with core diameter of just a few microns are used, requiring very high precision active alignment. The fibers can be directly bonded to the PIC with the adhesive within the light path. Using the adhesive outside the light path by bonding the fiber to an interposer is typically followed by filling the gap between fiber and PIC with an optical adhesive that matches the index of refraction (RI), minimizing the transmission loss caused by Fresnel-reflection. Another approach is to use microlenses on the PIC, allowing higher tolerances or enabling contactless connection (expanded beam connector).

Adhesive properties:

- Low shrinkage.

- Fast fixation.

- Low CTE.

- High Tg.

- RI matching.

- High transmission.

- Reflow stability.

|  |  |

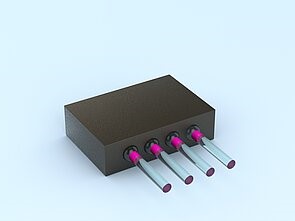

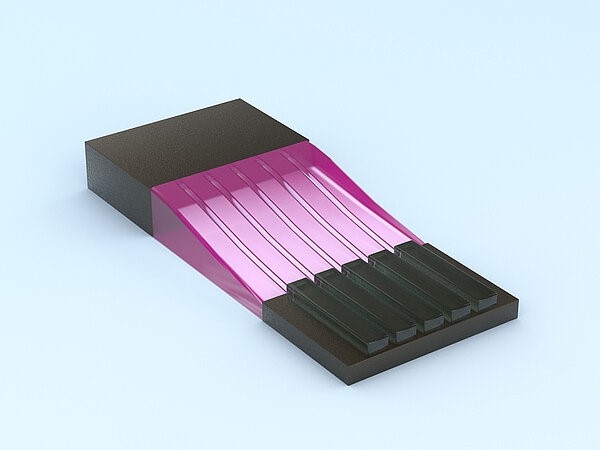

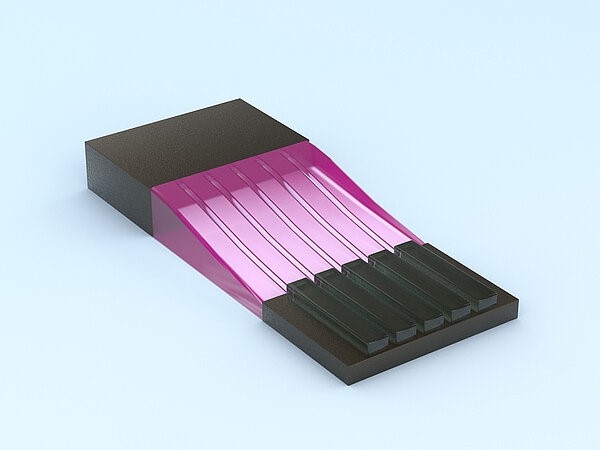

V-groove bonding

The use of V-groove structured substrates is common for passive alignment of fibers. Instead of connecting several single fibers to the PIC one by one, they can be pre-assembled by using V-grooves. The whole part, consisting typically of 12 fibers or more, can then be connected to the PIC in one step. The fibers are kept in the V-groove by bonding a lid on top. DELO adhesives can be dispensed before joining the lid or afterwards by an underfill process.

Adhesive properties:

- Suitable viscosity.

- Low CTE.

- Reflow stability.

Cladding

Short distance PIC to PIC or fiber to PIC connections can be achieved using photonic wire bonding. Similar to electrical wiring, an optical wire is used for interconnecting already assembled PICs and/or fibers. The photonic wire bonds can be 3D written by means of two-photon polymerization (2PP). For protecting the tiny wires, DELO offers a low index of refraction (RI) adhesive cladding that allows wave guiding by total inner reflection.

Adhesive properties:

- Low RI.

- Low viscosity.

- High reliability.

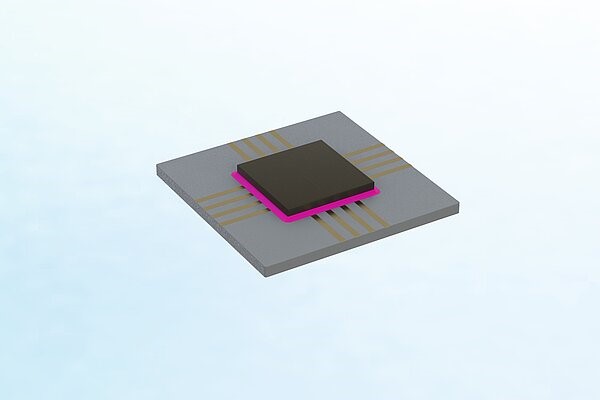

Chip attach

Attaching the PIC to a substrate or interposer is essential for photonic packaging. Reliable bonding with low CTE and sufficient bond strength are required. Additionally, DELO offers adhesives with light fixation that are beneficial for high accuracy and reducing the cycle time.

Adhesive properties:

- High bond strength.

- Low CTE.

- Low shrinkage.

- High reliability.

Source: DELO (https://www.delo-adhesives.com/us/)